a jukebox

A kind of on-demand seeding machine and seed technology, which is applied in the direction of single-grain seeding machine and seeding machine parts, etc., can solve the problems of uneven seeding, spreading, and huge structure of the seeding machine, so as to prevent seed jamming and damage seeds, avoid missing seeding, and improve The effect of the on-demand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

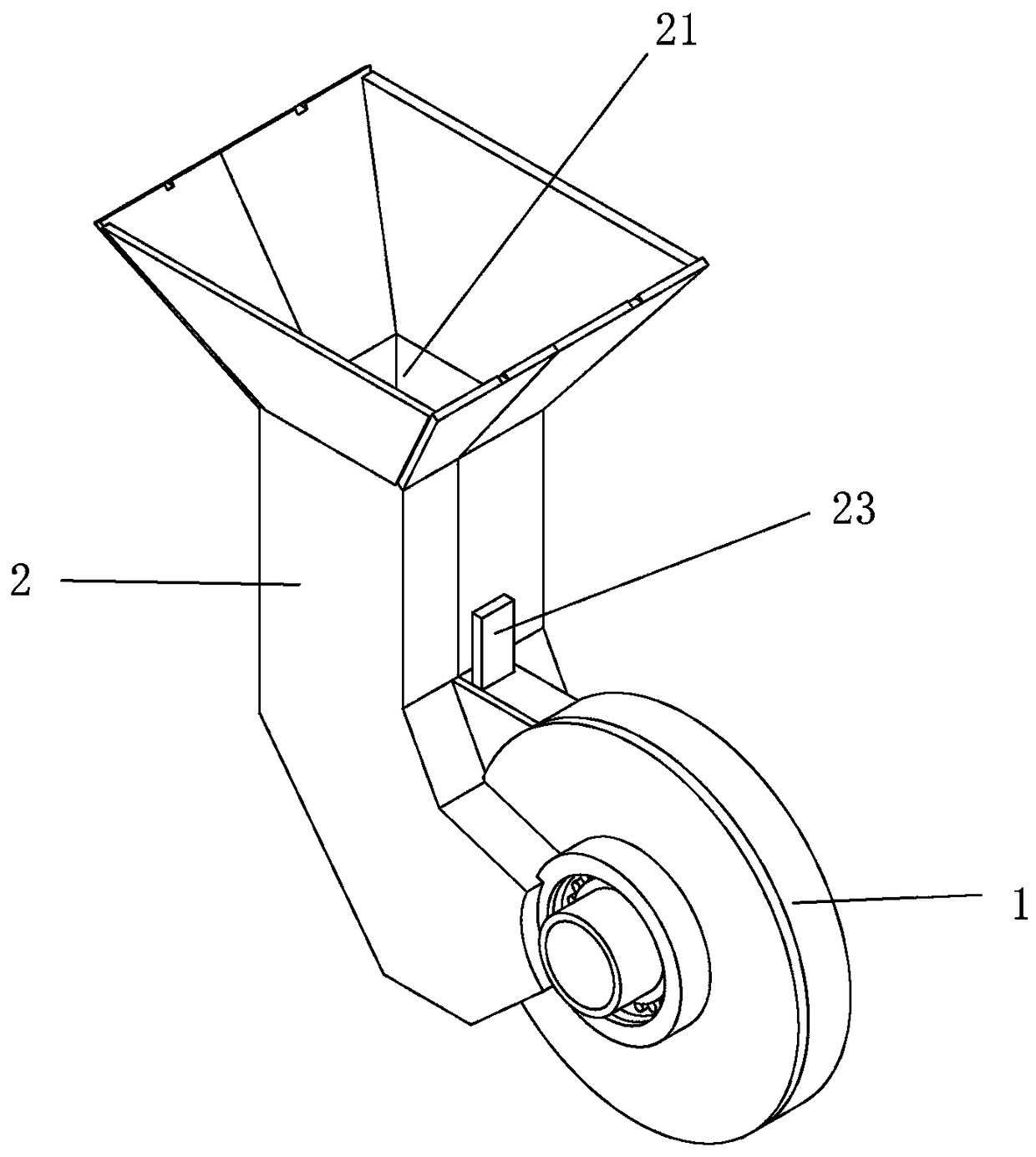

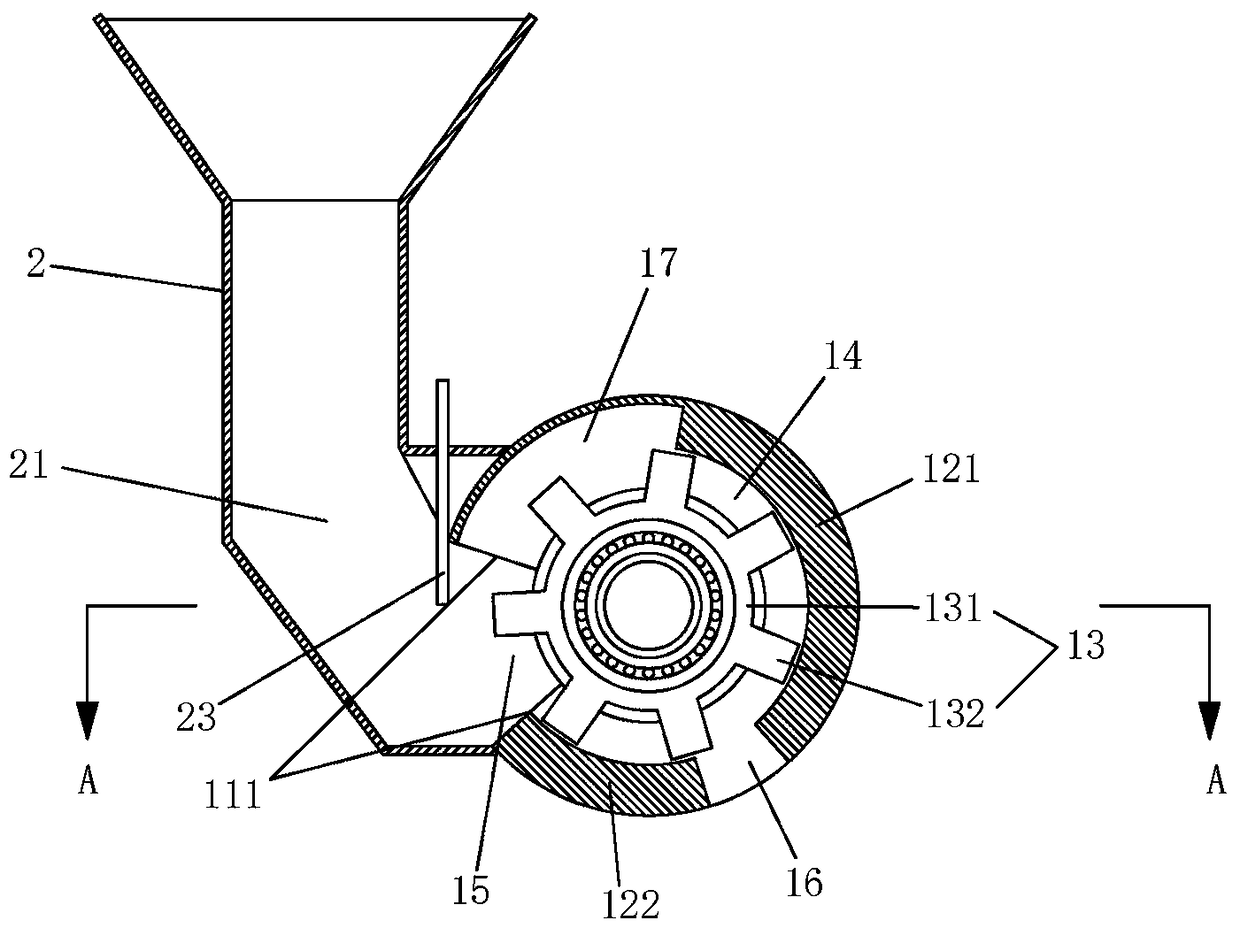

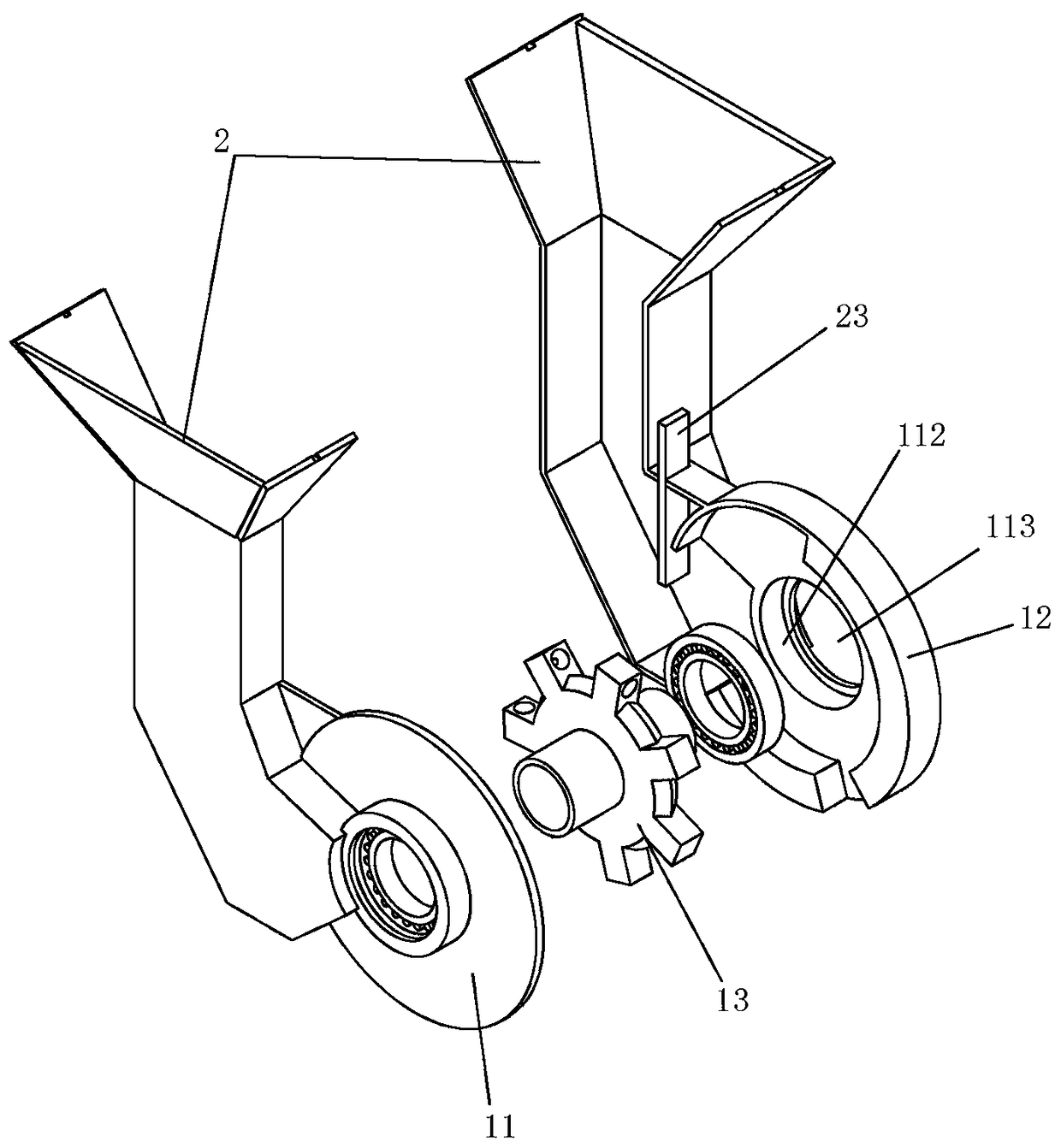

[0022] Example: such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a jukebox includes a dial assembly 1. The dial assembly 1 includes a dial chamber 14 and a dial member 13. The dial chamber 14 is matched by a blocking plate 12 and side baffles 11 on both sides of the blocking plate 12. A non-closed cavity structure is formed for accommodating the rotary dial 13 . The rotary dial 13 is arranged in the rotary dial cavity 14, and the seeds that enter the rotary dial cavity 14 through the seed inlet 15 are dialed out from the seed outlet 16 by using its own rotation, including a rotating body 131 and a number of uniformly arranged on the rotating body 131 Pick 132 on the peripheral surface. The seed inlet 15 is formed by the cooperation of the left and right baffles 11 and is arranged at the start of the dial chamber 14; the seed outlet 16 is formed by the cooperation of the left and right side baffles 11 and is arranged at the end of the dial chamber 14 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com