High pressure electric cooking pot

A high-voltage electric and hot pot technology, which is applied to pressure cookers, cooking utensil lids, cooking utensils, etc., can solve the problems of troublesome opening and closing of pot lids and cannot be used normally, and achieve the effect of convenient opening and closing of pot lids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

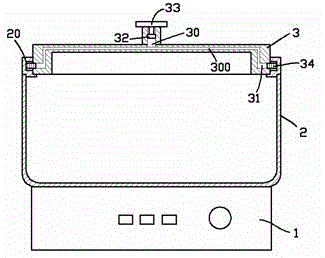

[0014] exist figure 1 In the shown embodiment one, the high-voltage electric heating pot includes a base 1, a pot body 2, and a pot cover 3; the upper port of the pot body 2 forms a horizontal ring groove 20, and the notch of the horizontal ring groove 20 faces the pot Inside; the center of the pot cover 3 vertically upwards to form a central slideway 30, and the central slideway 30 is connected to the horizontal slideway 31 symmetrically arranged on both sides of the pot cover through the hole 300; the inside of the central slideway 30 A vertically movable central slide 32 is provided, and the central slide 32 is vertically connected to the lid handle 33; the horizontal slide 31 is provided with a horizontally movable horizontal slide 34, and the horizontal slide The block 34 is matched with the horizontal ring groove 20; the channel between the central slide 32 and the transverse slide 34 is filled with liquid, and when the central slide 32 drops to the lower limit position,...

Embodiment 2

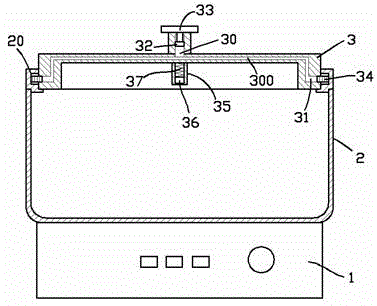

[0018] for figure 2 The second embodiment shown is different from the first embodiment in that: the center of the pot cover 3 extends vertically downwards with a lower slideway 35, and a permanent magnetic slideway 35 is provided in the lower slideway 35. block 36, and between the permanent magnet slider 36 and the bottom end of the lower slideway 35, a vacuum is provided, and a support spring 37 is provided; when the permanent magnet slider 36 is in the lower limit position, the support spring The elastic force of 37 is balanced with the standard atmospheric pressure; when the permanent magnet slider 36 is subjected to an upward pressure greater than 1 standard atmospheric pressure, it moves upward and further compresses the support spring 37 until the permanent magnet slider 36 is stressed balanced; the central slide 32 is also composed of permanent magnets, and is opposite to the same pole of the permanent magnet slider 36; the permanent magnet slider 36 has slid to the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com