An aluminum foil wrinkling machine

A creping machine and aluminum foil technology, applied in the equipment field of the aluminum foil technology field, can solve the problems of unsuitable aluminum foil, unstable pattern, complicated equipment, etc., and achieve the effects of stable pattern, simple structure and stable wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

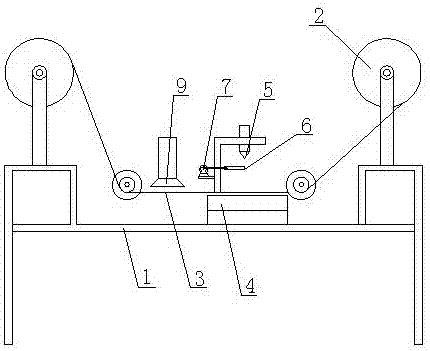

[0011] The present invention will be further described below in conjunction with accompanying drawing.

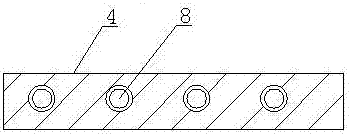

[0012] Such as figure 1 , 2 As shown, an aluminum foil wrinkling machine is characterized in that it includes a frame 1, and there is a roller 2 for conveying aluminum foil on the frame. 3. There is a bottom bracket 4 installed on the shelf under the aluminum foil path, and the top of the bottom bracket is close to the aluminum foil path. There is a metal layer on the bottom bracket, and the heating probe 5 is installed on the shelf above the aluminum foil path to face the aluminum foil path. There is a reciprocating baffle plate 6 below the heating probe, the baffle plate is connected to the power unit 7, and the reciprocating movement of the baffle plate can block the heating probe and illuminate the aluminum foil at intervals.

[0013] In this way, under the action of the baffle plate 6, the heating probe heats the aluminum foil intermittently, and the aluminum foil is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com