Electronic product assembly line workbench capable of achieving transverse moving

A technology for electronic products and workbenches, applied in assembly machines, manufacturing tools, metal processing equipment, etc., can solve the problems of inability to meet the requirements of modern assembly, low work efficiency of workers, and inhumane assembly, and achieve simple and convenient structure. Promotion and application, the effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

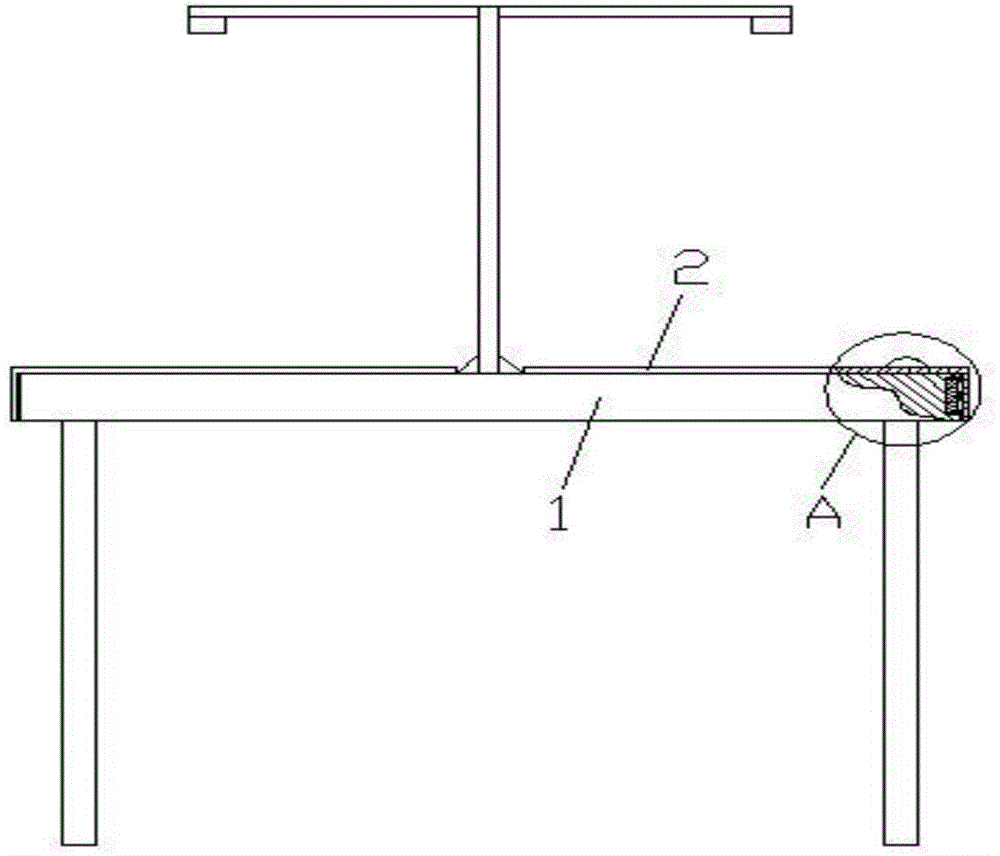

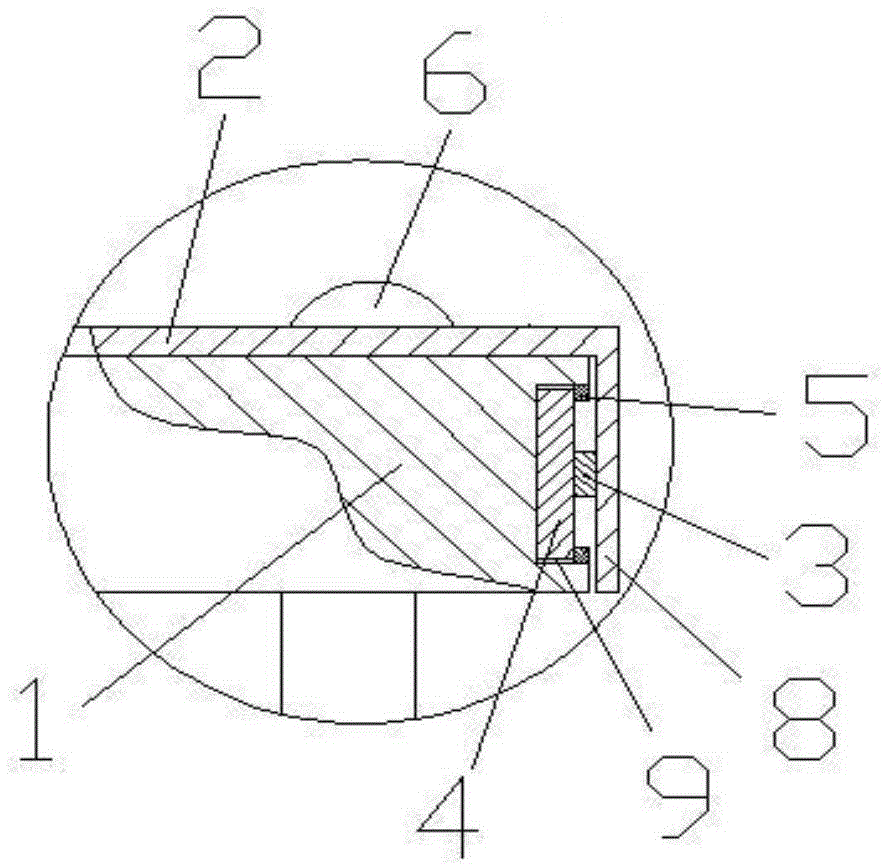

[0019] like figure 1 , figure 2 The shown workbench of a transversally movable electronic product assembly line includes a workbench 1, which is characterized in that: the upper part of the side surface of the workbench 1 close to the staff is provided with a U-shaped groove 9, and the U-shaped groove Two rollers 4 are arranged in parallel in the groove 9, and a cover plate is arranged on the workbench 1, and the cover plate includes a horizontal cover plate 2 installed on the upper surface of the workbench 1 and a vertical roller vertically connected with the horizontal cover plate 2. Cover plate 8, the vertical cover plate 8 is covered above the U-shaped groove 9, the inner side of the vertical cover plate 8 is connected with the roller 4 through the rotating shaft 3, and the distance between the two rollers 4 is less than that of the roller 4. Three times the diameter of the cross-section, the upper and lower sides of the U-shaped groove 9 are respectively provided with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com