Movement component for placement

A technology of moving components and driving components, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems affecting the quality and efficiency of product production, skewed assembly of electronic components, unstable moving mechanism, etc., to improve quality and efficiency, The effect of stable lateral movement and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

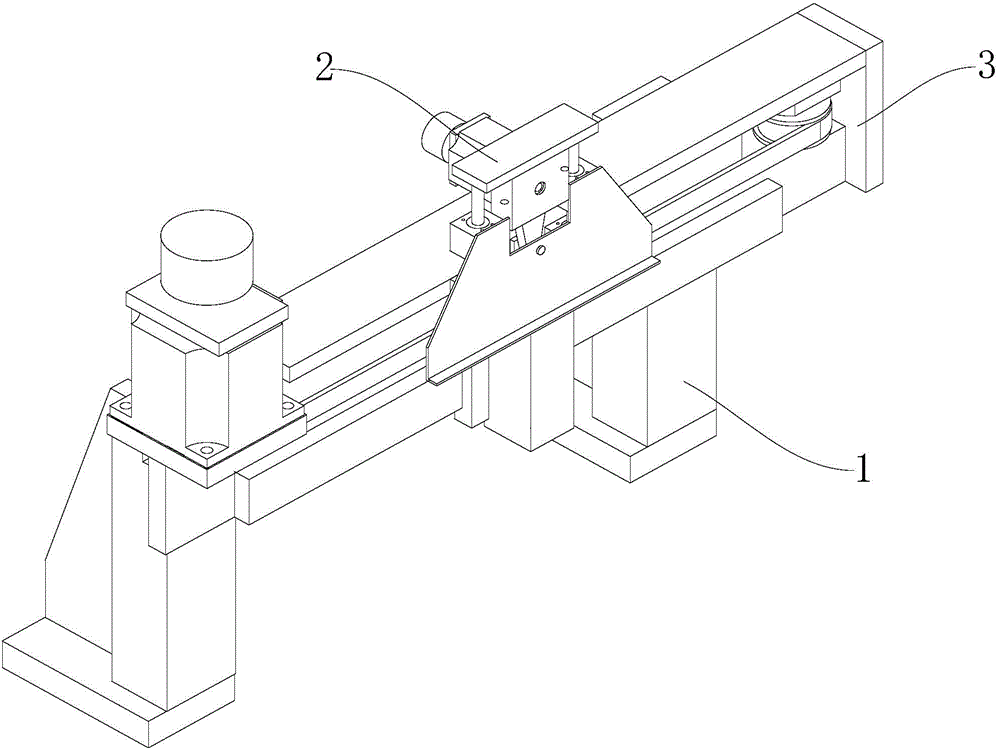

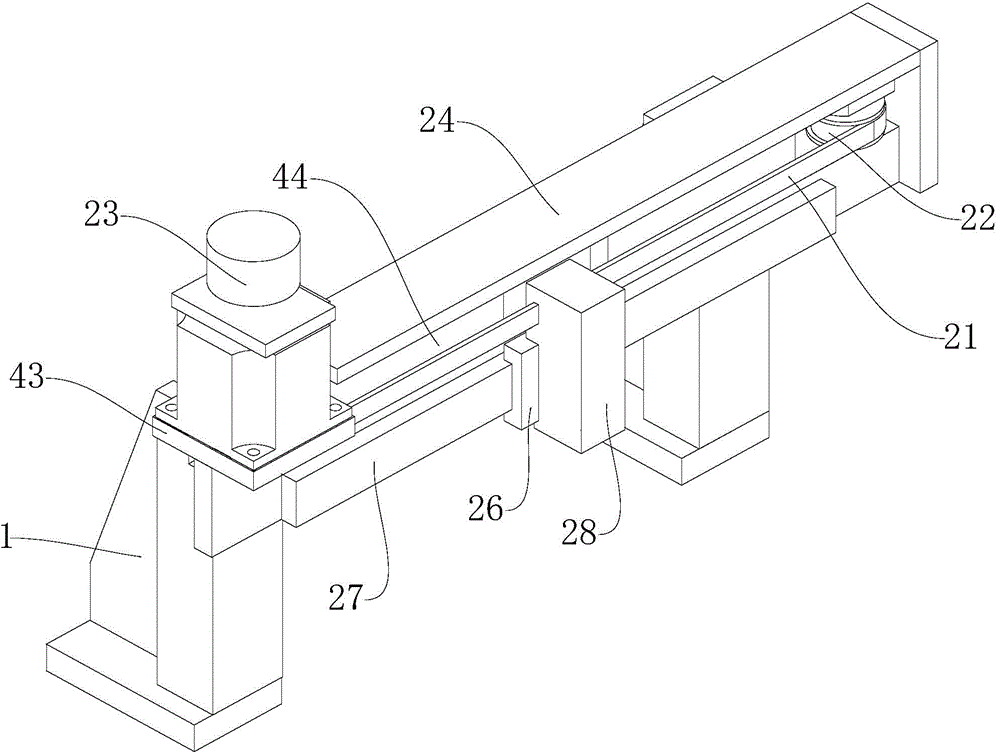

[0026] Such as Figure 1 to Figure 5 As shown, a moving assembly for placement is characterized in that it includes a horizontal drive assembly 2, a longitudinal drive assembly 3, and a support 1 for supporting the horizontal drive assembly 2;

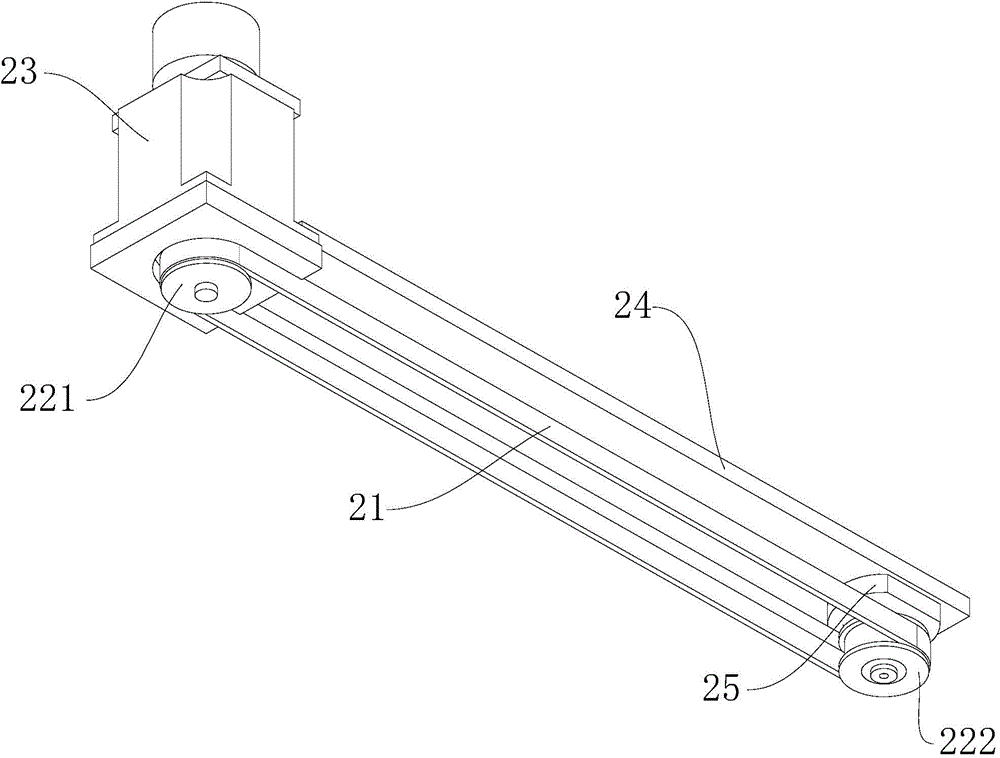

[0027] Described lateral driving assembly 2 comprises endless conveyor belt 21, acts on the transmission wheel assembly 22 of endless conveyor belt 21, is used to support the transmission wheel shaft 25 of transmission wheel assembly 22, is used to drive the horizontal stepping motor 23 of transmission wheel assembly 22 transmission, and The support 1 is fixedly connected to the fixed plate 44 installed vertically, the mounting plate 24 fixedly connected to the upper end surface of the fixed plate 44 and arranged horizontally, the slide rail 27 fixedly connected to the rear end surface of the fixed plate 44 and arranged parallel to the fixed plate 44, The horizontal slider 26 which is arranged on the slide rail 27 and can move laterall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com