A tool and method for measuring the accuracy of the c-axis angle of a turn-milling compound machining center

A compound machining center and shaft angle technology, which is applied in metal processing equipment, metal processing machine parts, manufacturing tools, etc., can solve the problems of undetectable, unrotatable axis positioning accuracy, correction and compensation, etc., and achieve saving inspection, simple and fast Effect of Detection and Correction Methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

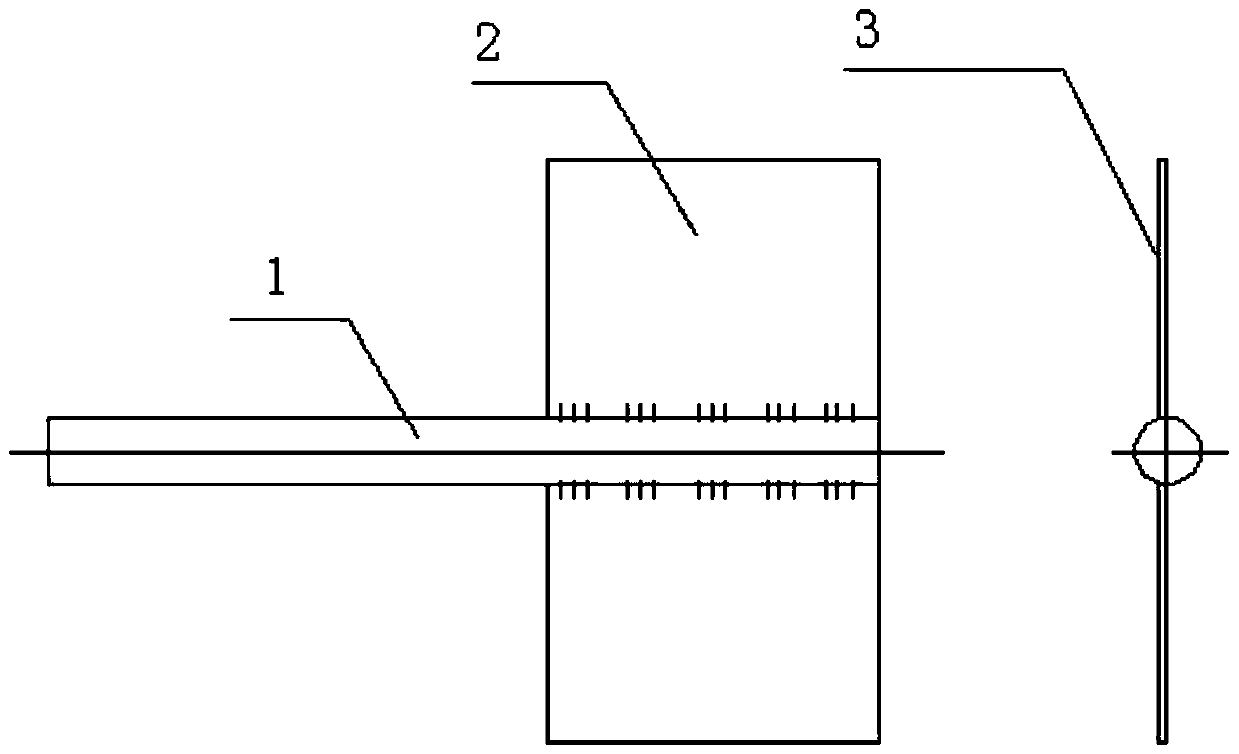

[0012] Reference attached figure 1 , the tooling of the present invention includes a round bar 1 and a flat plate 2. One end of the round bar 1 is provided with a stepped plane along the axial direction of the round bar.

[0013] One end of the round rod 1 can also be provided with parallel grooves, and the flat plate 2 can be installed and fixed in the parallel grooves along the axial direction of the round rod.

[0014] The present invention also provides a method for measuring the accuracy of the C-axis angle of the turning-milling compound machining center, which is characterized by comprising the following steps:

[0015] Step 1, self-made a set of tooling, the tooling includes a round rod and a flat plate, a step plane is milled out along the axis of the round bar at one end of the round bar, the flat plate is fixed on the step plane of the round bar, and the other side is ground Machining, as the reference measurement surface;

[0016] Step 2: Position the C-axis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com