Outer flanging crawler wheel

A track wheel and flanging technology, applied in the direction of wheels, transportation and packaging, vehicle parts, etc., can solve the problems of poor structural strength, track wheels can only be used as track wheels, etc., and achieve the effect of good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

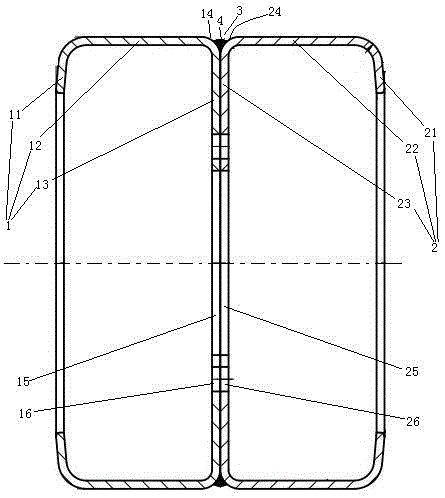

[0023] Embodiment one, see figure 1 , an outturned track wheel, comprising an outer half wheel 1 and an inner half wheel 2.

[0024] The outer half wheel 1 is provided with an outer inner flange 11, an outer track support ring 12 and Outer half spoke 13. The outer inner flange 11, the outer track support ring 12 and the outer half-spoke 13 are connected together in one structure. An outer chamfered surface 14 is provided between the outer track support ring 12 and the outer half-spoke 13 . The outer half spoke 13 is provided with an outer half central hole 15 and an outer half mounting hole 16 .

[0025] The inner half wheel 2 is provided with an inner inner flange 21 , an inner track support ring 22 and an inner half spoke 23 sequentially from the inner side to the outer side. The inner flange 21, the inner track support ring 22 and the inner half-spoke 23 are connected together in one structure. An inner chamfer surface 24 is provided between the inner track support rin...

Embodiment 2

[0027] Embodiment two, the difference with embodiment one is:

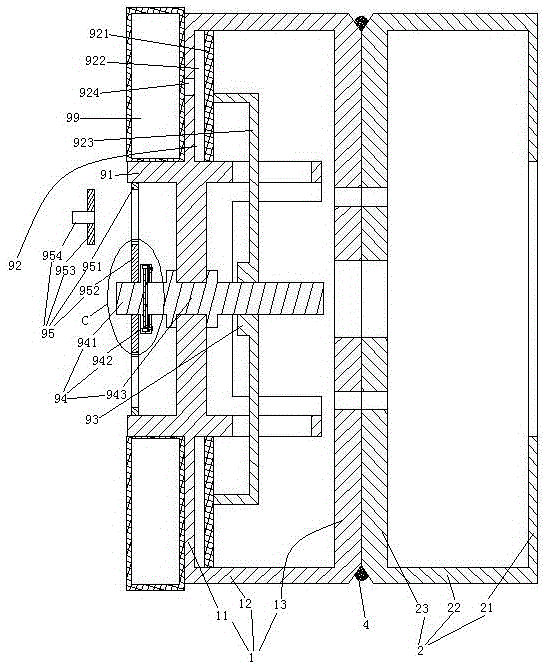

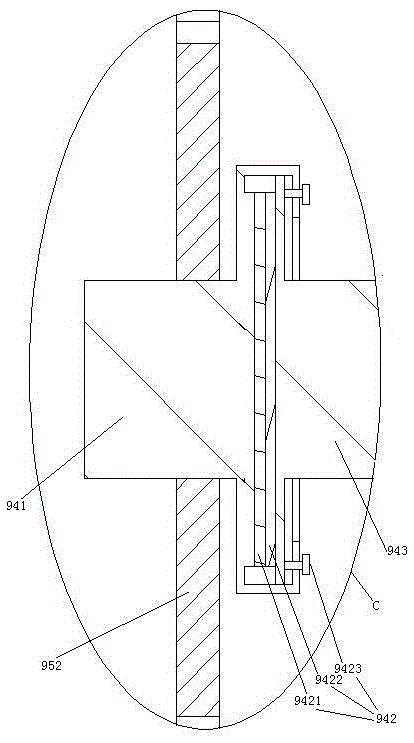

[0028] see figure 2, also includes a support mode switching mechanism 9. A tire support ring 91 is provided on the outer side of the outer inner flange 11 . The tire support ring 91 is coaxially fixed together with the outside half-wheel 1. The tire support ring 91 and the outer track support ring 12 are distributed along the axial direction of the outer half wheel 1 . A pneumatic tire 99 is provided on the tire support ring 91 . The support mode switching mechanism 9 includes an air storage cylinder 92 , a threaded sleeve 93 , a screw rod 94 and a differential mechanism 95 . The outer half wheel 1 is provided with an anti-rotation structure 911 . The anti-rotation structure 911 is an elongated hole disposed on the outer half wheel 91 and extending axially along the rim. The air storage cylinder 92 is arranged inside the outer inner flange 11 . The air storage cylinder 92 is an annular cylinder coaxial wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com