Candy conveying device

A transfer device and candy technology, applied in packaging and other directions, can solve the problems of high maintenance cost, reduced production efficiency, high failure rate of sugar-packing components and compression springs, simplified mechanical mechanism, reduced accident rate, and strong market promotion. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and specific embodiments:

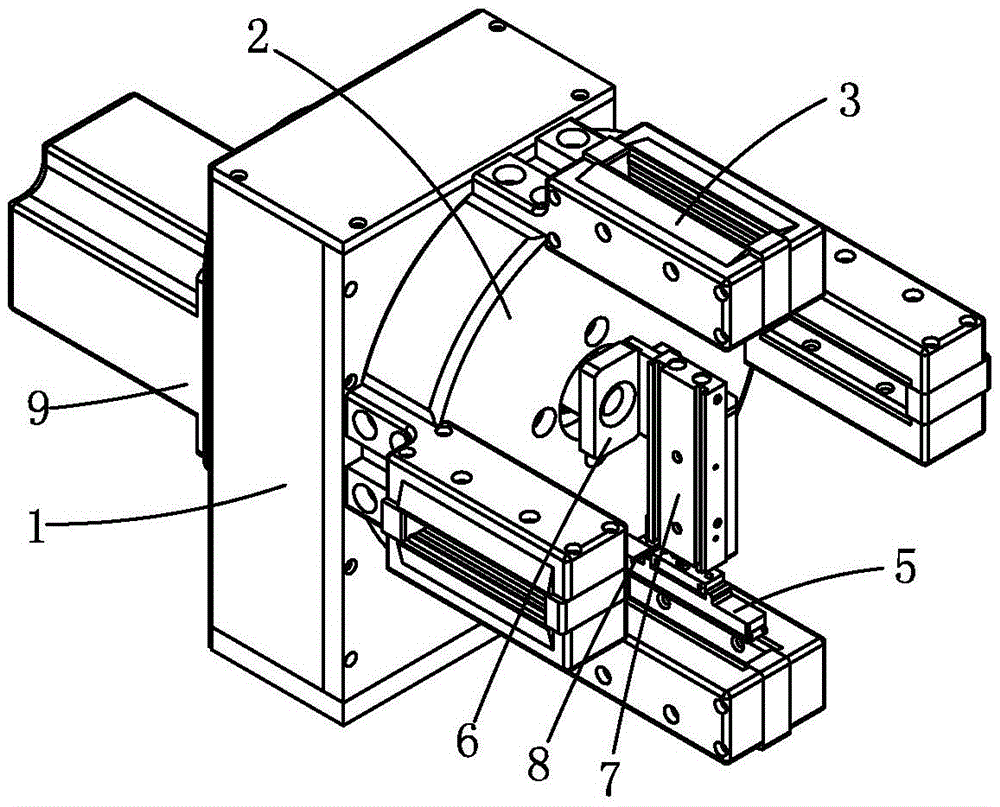

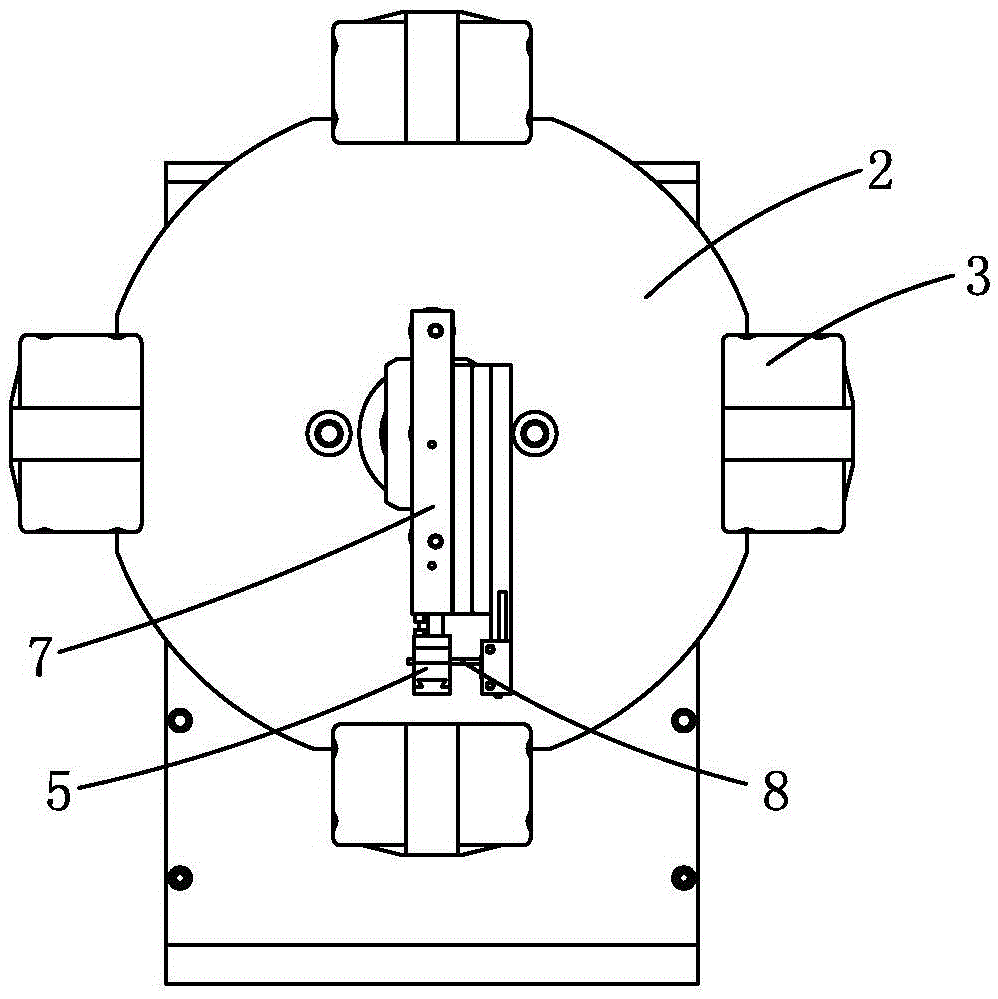

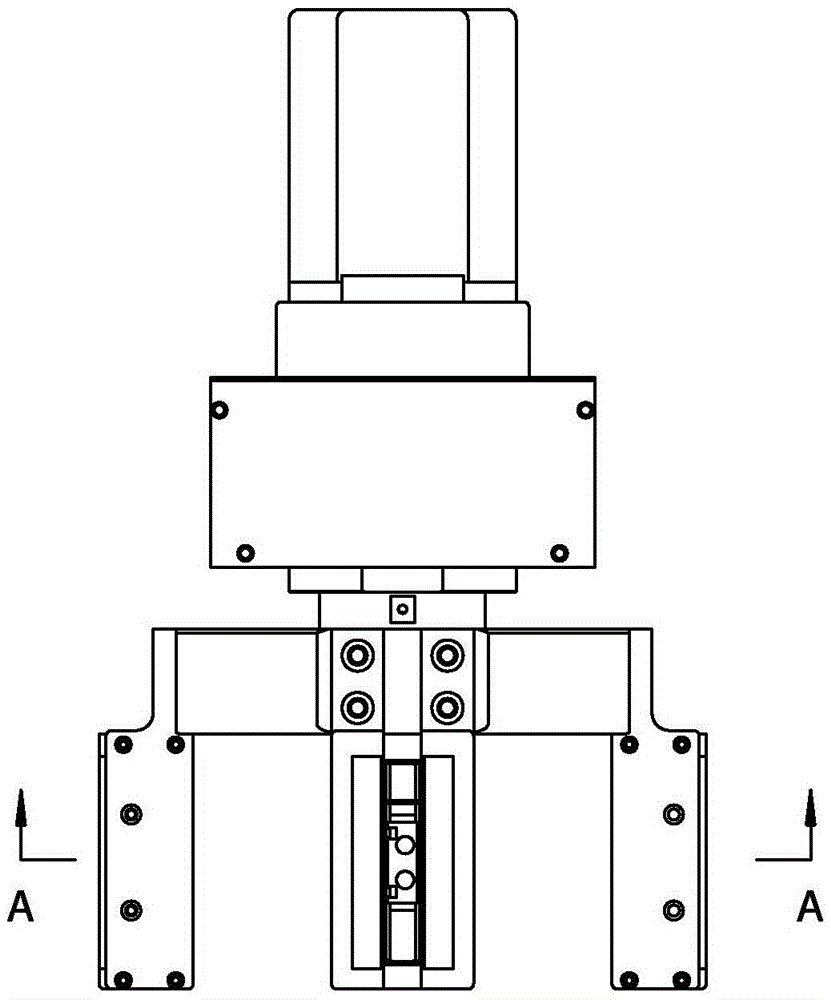

[0018] Such as Figure 1 to Figure 4 As shown, the candy transfer device for candy inner box packaging equipment of the present invention includes a rack 1 for installing various components. The rack 1 is equipped with a turntable 2, the turntable 2 and a motor 9, so that it can intermittently surround its center. Each time it rotates, the angle of rotation is 90°; four sugar transfer arms 3 are evenly distributed on the circumference of the turntable 2, and each transfer sugar swing arm 3 is provided with two retractable sugar holding parts 4 oppositely. The sugar holding part 4 is provided with grooves matching the shape of the candy 10, and the grooves on the sugar holding parts 4 opposite to each other on the sugar swing arm 3 are arranged opposite to each other. Specifically, the sugar holding parts 4 are connected to each other through an elastic element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com