Tobacco containing device of tobacco clamp in curing barn

A cigarette clip and cigarette loading technology, which is applied in the fields of tobacco, tobacco preparation, transportation and packaging, etc., can solve the problems of poor transportation stability and easy jamming of off-chain cigarette clips, and achieve stable and safe lifting, stable and safe transportation Reliable, Simple Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

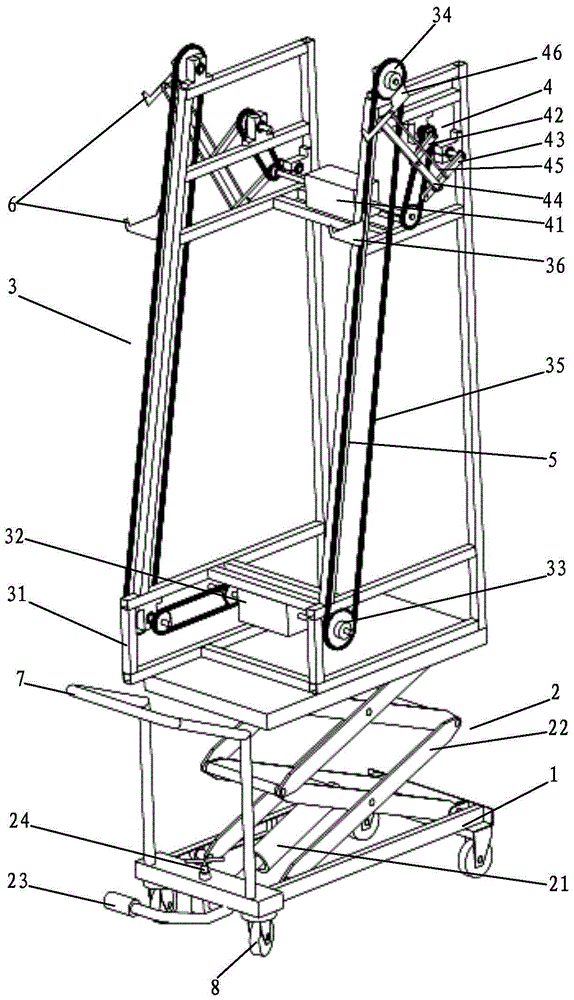

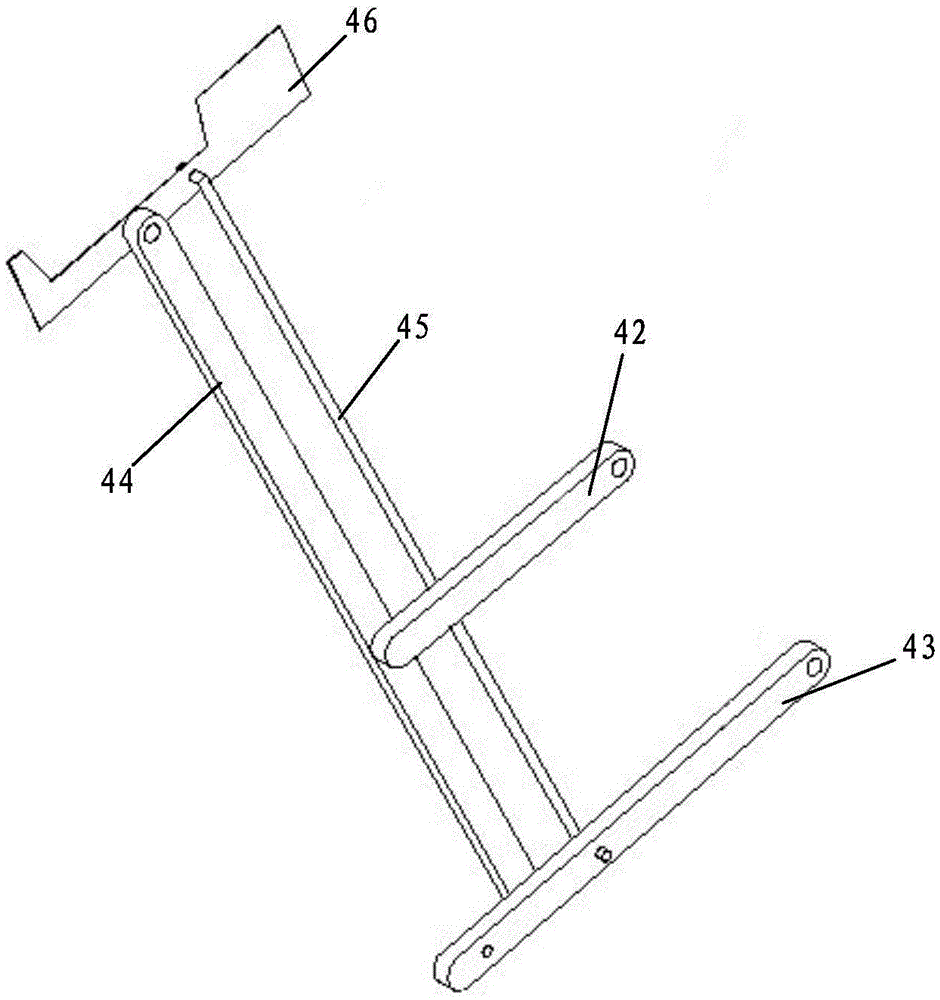

[0027] refer to figure 1 , this embodiment relates to a cigarette clamping device, including a frame 1 and a lifting device 2, a conveying device 3 and a straightening device 4 arranged on the frame 1, the output end of the lifting device 2 is connected to the conveying device The device 3 is connected, and the straightening device 4 is located at the end of the conveying channel on the conveying device 3; the conveying device 3 includes a mount 31, a first motor 32, a driving wheel 33, a driven wheel 34, a chain 35 and a On the first handle 36 where the cigarette holder is placed, the first motor 32 is fixedly mounted on the bottom of the mounting base 31, the driven wheel 34 is rotatably mounted on the upper part of the mounting base 31, and the driving wheel 33 It is fixedly installed on the first motor 32, and is driveably connected with the driven wheel 34 through a chain 35. The first support handle 36 is fixedly installed on the chain 35; the inner side of the chain 35 ...

Embodiment 2

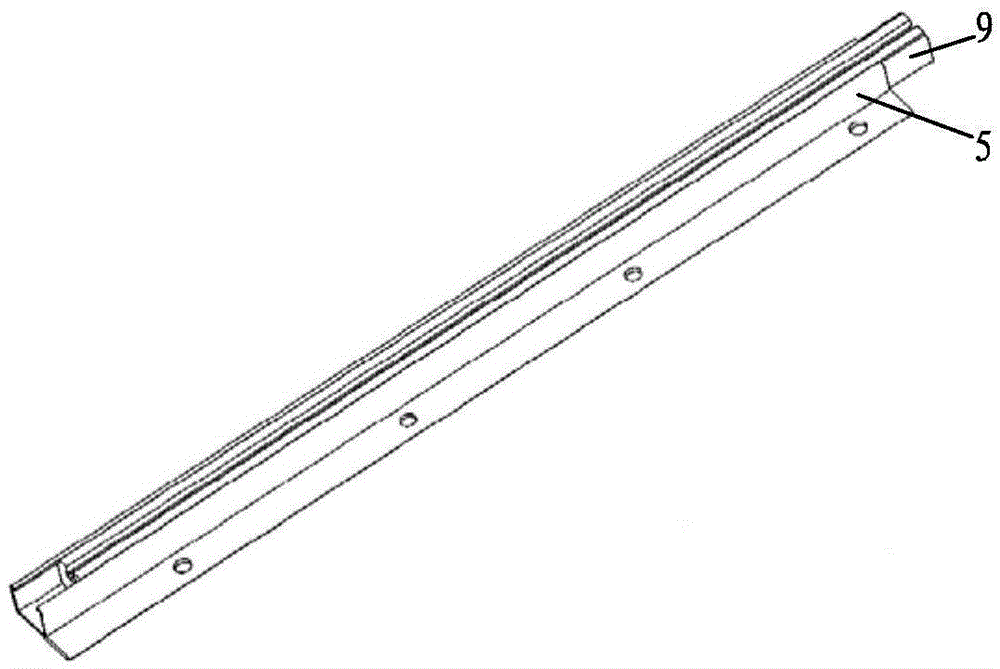

[0036] This embodiment is on the basis of Embodiment 1, as an improvement to the protective guide rail 5, as image 3 and 4 As shown, the guard guide rail 5 is nested with a clip 9 , and the clip 5 is provided with a guide groove 91 for guiding the first handle 36 . The cross-section of the guide groove 91 is a "ten"-shaped structure, and the first support handle 36 is sleeved in the guide groove 91 , and moves linearly along the guide groove 91 under the guidance of the guide groove 91 . Since the first handle 36 is constrained by the guide groove 91, the chain 35 connected to the first handle 36 is also constrained. After the chain 35 bears the gravity of the cigarette clip, under the support of the protective guide rail 5, the chain 35 will not The deformation can keep the linearity of the movement of the chain 35, thereby preventing the chain 35 from falling off due to lateral force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com