Novel bearing steel

A kind of bearing steel, a new type of technology, applied in the field of bearing steel, can solve the problems of bearing steel steel quality, poor performance stability, hard toughness of bearing steel that cannot meet the demand, poor appearance quality, etc., and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] Example 1: carbon: 0.15%; chromium: 0.05%; sulfur: 0.001%; nickel: 3.20%; aluminum: 0.015%; vanadium: 0.04%; Phosphorus ≤ 0.020%; the balance is Fe and unavoidable impurities.

Embodiment 2

[0011] Example 2: carbon: 0.18%; chromium: 0.15%; sulfur: 0.005%; nickel: 3.10%; aluminum: 0.020%; vanadium: 0.04%; Phosphorus ≤ 0.020%; the balance is Fe and unavoidable impurities.

Embodiment 3

[0012] Example 3: carbon: 0.16%; chromium: 0.25%; sulfur: 0.001%; nickel: 3.50%; aluminum: 0.040%; vanadium: 0.08%; Phosphorus ≤ 0.020%; the balance is Fe and unavoidable impurities.

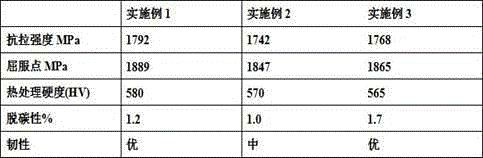

[0013] Table 1 Performance comparison of various low-alloy steels.

[0014]

[0015] Experiments show that the bearing steel shown in the invention has good mechanical properties and fatigue strength, and at the same time reduces the overheating sensitivity and decarburization tendency of the steel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com