Composite reinforced bamboo pipe component with inner fillers and preparation method thereof

A technology of bamboo tubes and components, which is applied in the field of composite inner filler reinforced bamboo tube components and its preparation, can solve the problems of weak bending moment resistance, underutilization of hollow parts, and large differences in individual strength, so as to improve bending resistance. The effect on the performance under pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a composite inner filler reinforced bamboo tube member, which is mainly used for bending members such as beams and boards of buildings.

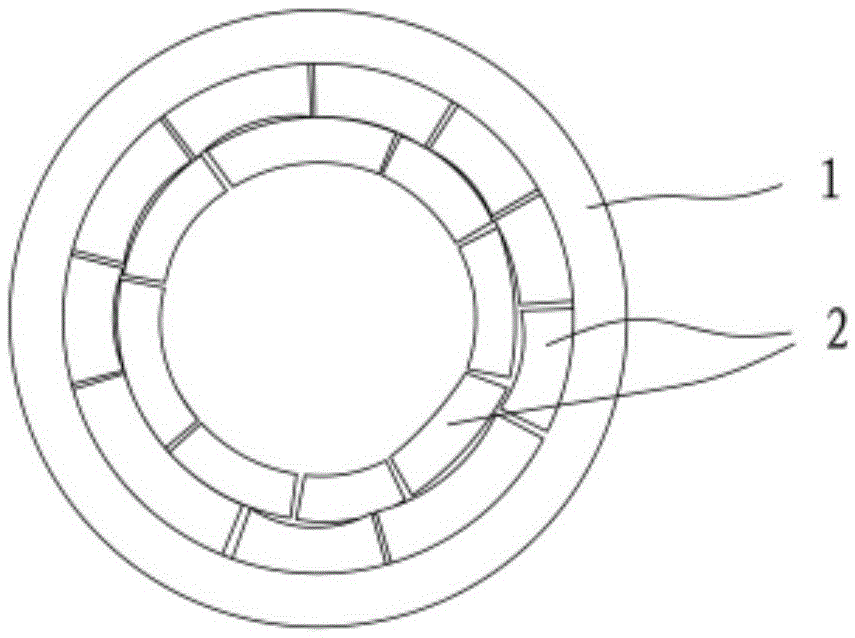

[0028] Such as figure 1 As shown, the bamboo tube member includes a bamboo tube 1 and a plurality of bamboo strips 2 located in the bamboo tube 1, and the bamboo strips 2 are provided with one or more turns, figure 1 The middle bamboo strip 2 is provided with two circles, and the surface of the bamboo strip 2 is coated with epoxy resin glue to arrange and fix around the inner wall of the bamboo tube 1. The diameter of bamboo tube 1 is 10~15cm.

[0029] The preparation process of the present embodiment bamboo tube member is as follows:

[0030] S1. Cut off several bamboo tubes 1 with good straightness, open the internal bamboo joints, split some bamboo tubes 1 longitudinally and cut them into bamboo strips 2 with the same length as the bamboo tubes 1.

[0031] S2. Anti-corrosion treatment, remove the bamboo ...

Embodiment 2

[0035] This embodiment provides a composite inner filler reinforced bamboo tube component, which is mainly used for compression components such as columns and walls of buildings.

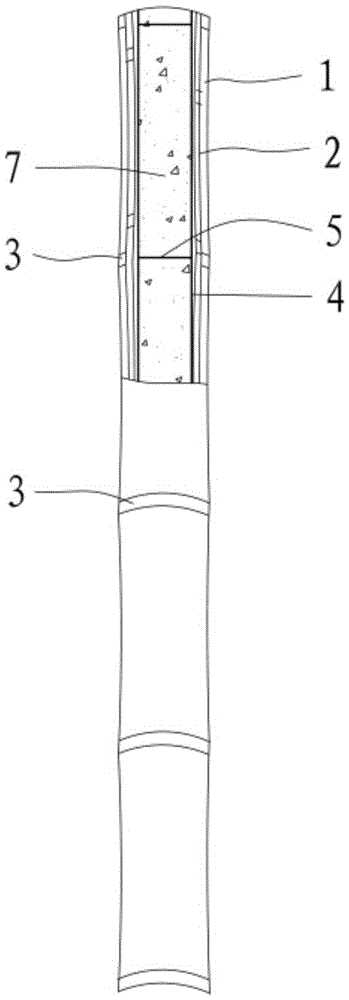

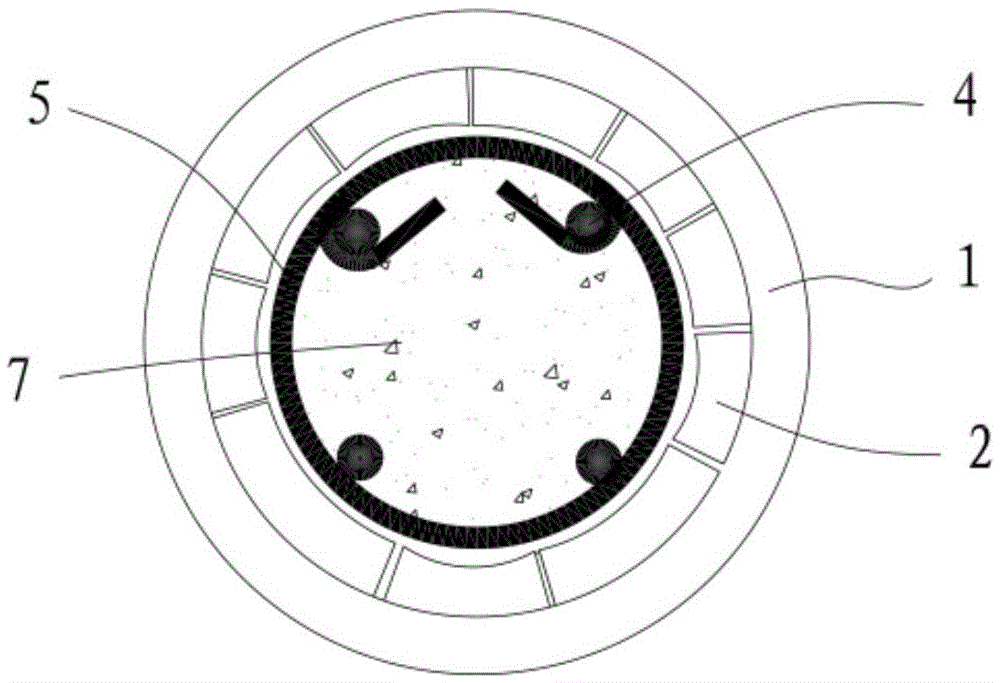

[0036] Such as figure 2 , image 3 As shown, the bamboo tube member includes a bamboo tube 1 and a plurality of bamboo strips 2 located in the bamboo tube 1. The bamboo strips 2 are provided with one or more turns, and the surface of the bamboo strips 2 is coated with an environmentally friendly high temperature resistant toughened epoxy resin. The inner walls of the bamboo tubes 1 are arranged and fixed. The diameter of bamboo tube 1 is 10~15cm. The inside of the bamboo tube 1 is also provided with longitudinal stress bars 4 and several circular stirrup bars 5 . Stirrups 5 are arranged at intervals of 3 along the bamboo tube 1 bamboo joint, and the stirrups 5 are welded and fixed on the longitudinal stress bars 4 . Concrete is poured between the bamboo tube 1 and the longitudinal reinforcement...

Embodiment 3

[0041] This embodiment provides a composite inner filler reinforced bamboo tube component, which is mainly used for compression components such as columns and walls of buildings.

[0042] Such as Figure 4 , Figure 5 As shown, the bamboo tube member includes a bamboo tube 1 and a plurality of bamboo strips 2 located in the bamboo tube 1. The bamboo strips 2 are provided with one or more turns, and the surface of the bamboo strips 2 is coated with an environmentally friendly high temperature resistant toughened epoxy resin. The inner walls of the bamboo tubes 1 are arranged and fixed. The diameter of bamboo tube 1 is 10~15cm. The inside of the bamboo pipe 1 is also provided with a steel pipe 6, the steel pipe 6 is coaxially packed into the bamboo pipe 1, and a concrete layer 7 is poured between the steel pipe 6 and the bamboo pipe 1 and inside the steel pipe 6.

[0043] The preparation steps of the bamboo tube member in this embodiment are as follows: Steps S1-S4 are the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com