Air conditioner duct flow rate controller

An air-conditioning duct and controller technology, which is applied to heating and ventilation control systems, space heating and ventilation, heating methods, etc. The effect of reducing wind resistance, high clamping force and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

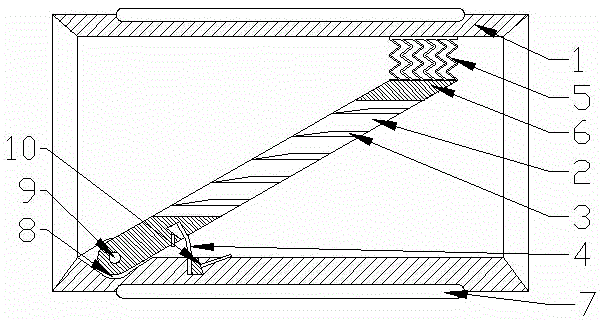

[0026] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

[0027] Such as figure 1 As shown, the present invention is an air-conditioning pipeline flow rate controller. The controller includes a beam tube 1 installed on the inner wall of the air-conditioning duct. A windward plate 6 is provided in the beam tube 1, and the An exhaust hole 2 is provided in the middle of the windward plate 6, in which a plurality of windward fins 3 are fixed in an array, and the cross section of the axial ends of the windward fin 3 in the width direction is triangular; The inner wall of the flow tube 1 is rotationally connected, and a resistance strain gauge 4 is provided between the inner wall of the beam tube 1 and the rotating connection end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com