Self-rotary ceramic product processing oven

A self-rotating, ceramic technology, applied in the drying, drying, dryer and other directions of ceramic products, can solve the problems of inability to separate the box, no air conduction, inconvenient cleaning, etc. Easy installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

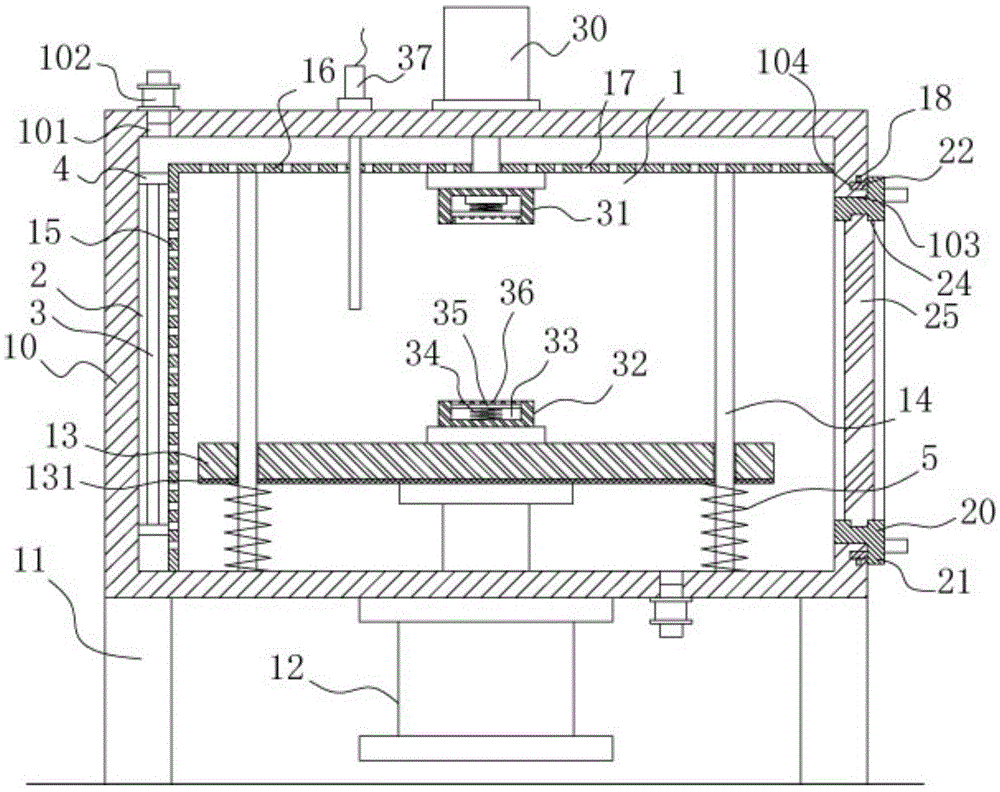

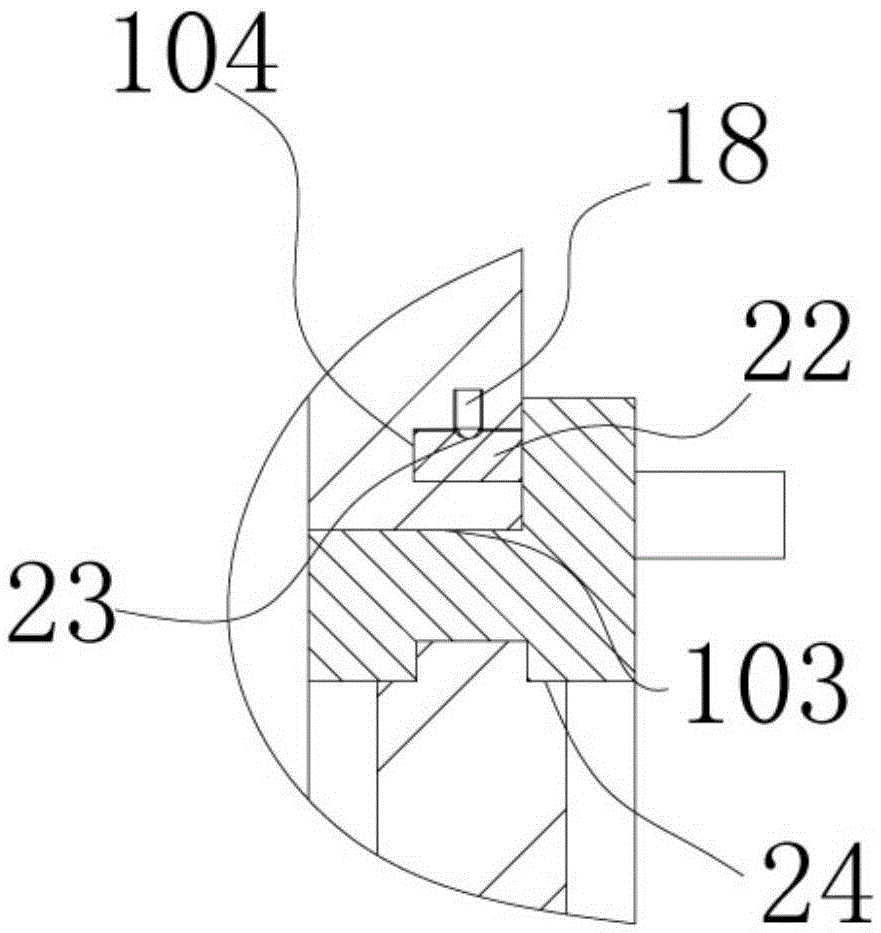

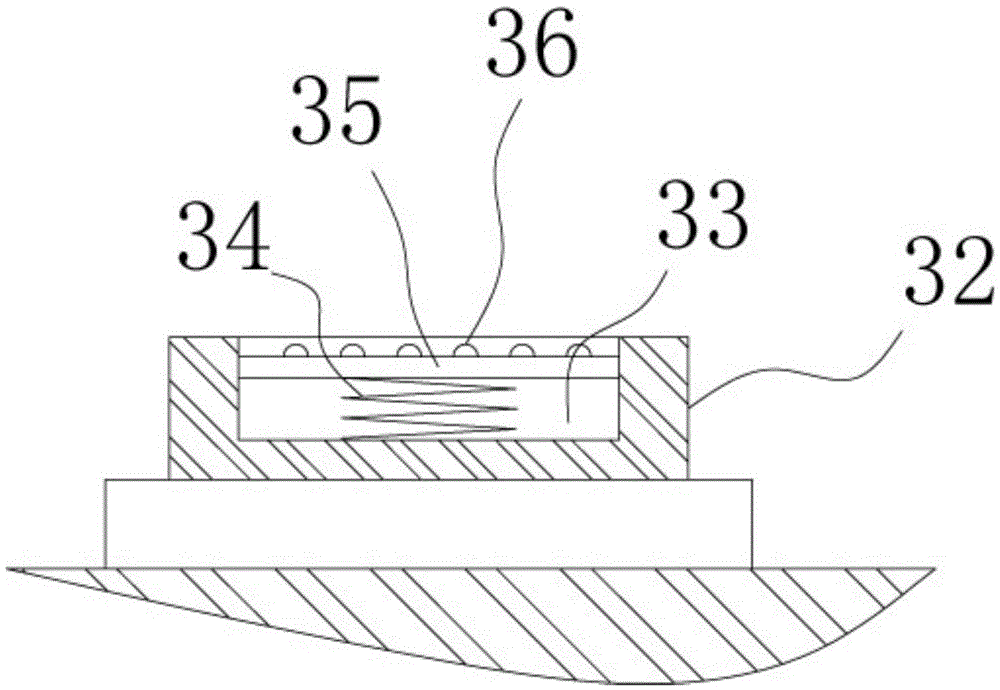

[0020] Example: see Figure 1 to Figure 3 As shown, a self-rotating ceramic product processing oven includes a box body 10, a plurality of legs 11 are fixed on the bottom surface of the box body 10, a push cylinder 12 is fixed on the bottom surface of the bottom plate of the box body 10, and the push cylinder 12 The push rod vertically extends upwards into the casing 10, and the end of the push rod that promotes the cylinder 12 is fixed with a placement plate 13, and the placement plate 13 is in the casing 10. The bottom plate of the box body 10 at the side is fixed with an inner dividing plate 15, and the top surface of the three inner dividing plates 15 is fixed on the upper top plate 16, and the three inner dividing plates 15 and the upper top plate 16 will box body 10 Separated into a placement cavity 1 and a heating cavity 2, the placement plate 13 is placed in the placement cavity 1, the heating rod 3 is installed in the heating cavity 2, a plurality of guide support rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com