Temperature-difference temperature measuring device

A temperature measuring device and temperature difference technology, which is applied in the direction of liquid level indicators for physical variable measurement, can solve problems affecting sensor measurement data, etc., and achieve the effects of ensuring detection sensitivity, preventing contact thermal resistance, and good heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

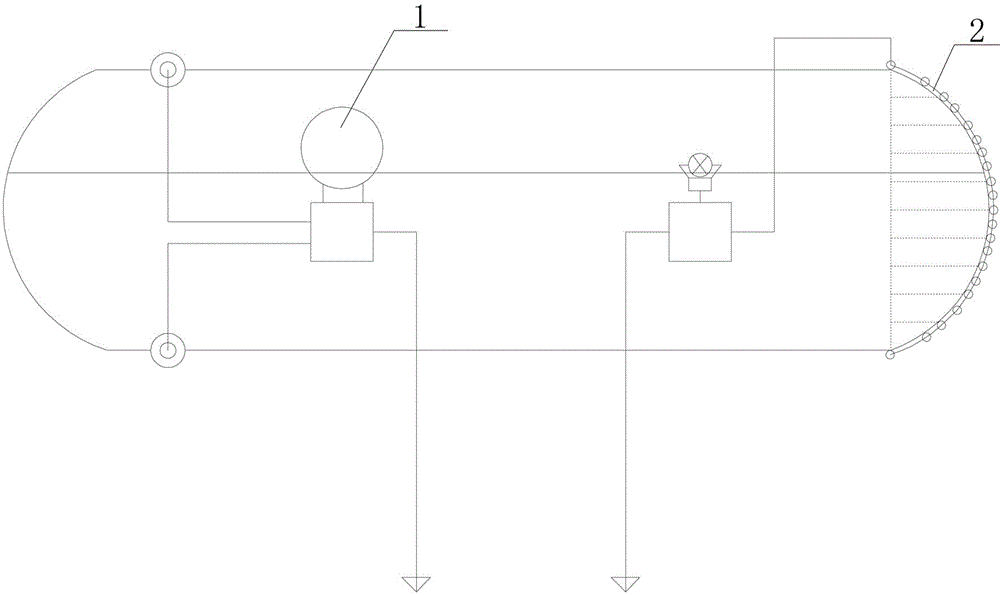

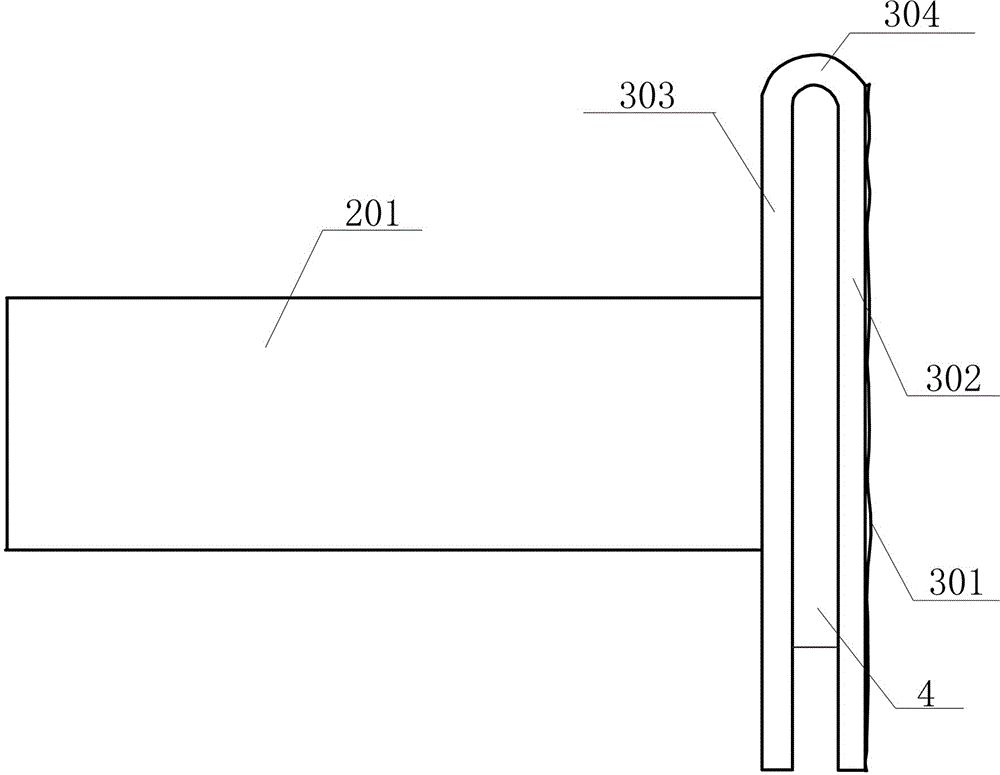

[0019] Such as figure 1 and figure 2 Shown is a temperature difference type temperature measuring device, which includes a liquid level gauge 1, a sensor array 2 is arranged on the liquid level gauge 1, and the sensors in the sensor array 2 include sensor probes, and a heat conduction structure is arranged on the sensor probe, and the heat conduction structure Including a flexible heat conduction layer 301 , the flexible heat conduction layer 301 is pasted on the first heat conduction part 302 , the first heat conduction part 302 and the second heat conduction part 303 are connected by a connector 304 , and the second heat conduction part 303 is connected with the sensor probe 201 .

[0020] The first heat conduction part 302 , the second heat conduction part 303 , and the connecting piece 304 form a U-shaped structure, and the elastic piece 4 is arranged in the U-shaped structure.

[0021] The flexible thermal conduction layer 301 is a silicone layer.

[0022] The first he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com