Water immersion type ultrasonic detecting system for aluminum alloy flat casting ingots and using method thereof

An ingot water immersion, detection system technology, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, measuring devices, etc., can solve the problems of poor accuracy and detection efficiency, etc. Achieve high reproducibility, high repeatability, and good beam directivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

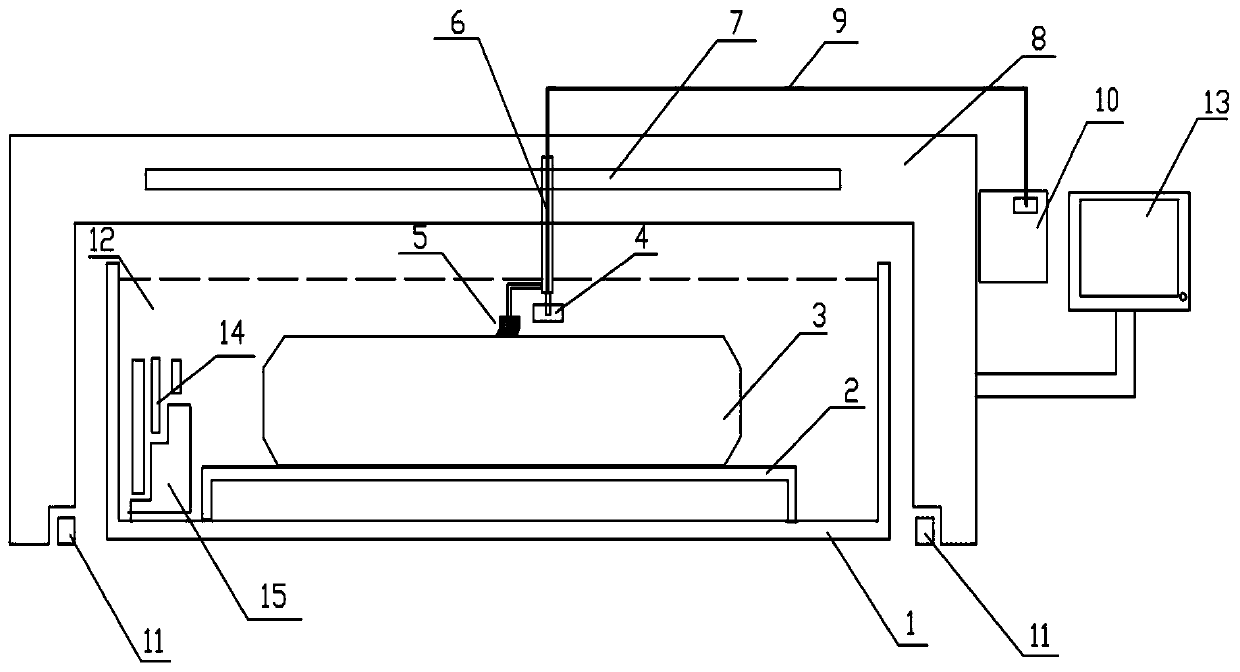

[0060] Such as figure 1As shown, an aluminum alloy flat ingot water immersion ultrasonic detection system includes: ultrasonic water tank (1), movable support frame (2), water immersion phased array ultrasonic probe (4), bubble brush (5), Z-direction movement axis (6), Y-direction track (7), scanning bridge and electrical system (8), probe cable (9), phased array ultrasonic instrument (10), X-axis track (11), industrial computer ( 13), test block bracket (15), wherein, the bottom of the ultrasonic water tank (1) is provided with a movable support frame (2) for carrying the aluminum alloy flat ingot (3) to be tested, and one side wall of the ultrasonic water tank A test block support (15) is provided between the movable support frame (2) for carrying the ultrasonic test block group (14), and deionized water (12) is injected as an ultrasonic coupling agent in the ultrasonic water tank (1) The upper end of the Z-direction motion shaft (6) is slidably connected to the Y-direction...

Embodiment 2

[0062] It is necessary to use the hardware and technical methods of the phased array ultrasonic system to perform non-destructive evaluation on the 7075 brand aluminum alloy flat ingot with a specification of 500mmX1650mmX5000mm. According to the alloy phase diagram calculation and practical experience, it is speculated that the composition of the alloy, such as improper control of casting process parameters, has a greater tendency to form Alx(Cr,Mn)y aggregated coarse metal compound defects. For the non-destructive quality control of Alx(Cr,Mn)y aggregated coarse metal compound defects, the aluminum alloy flat cast ingot water immersion ultrasonic detection system described in Example 1 is used for detection,

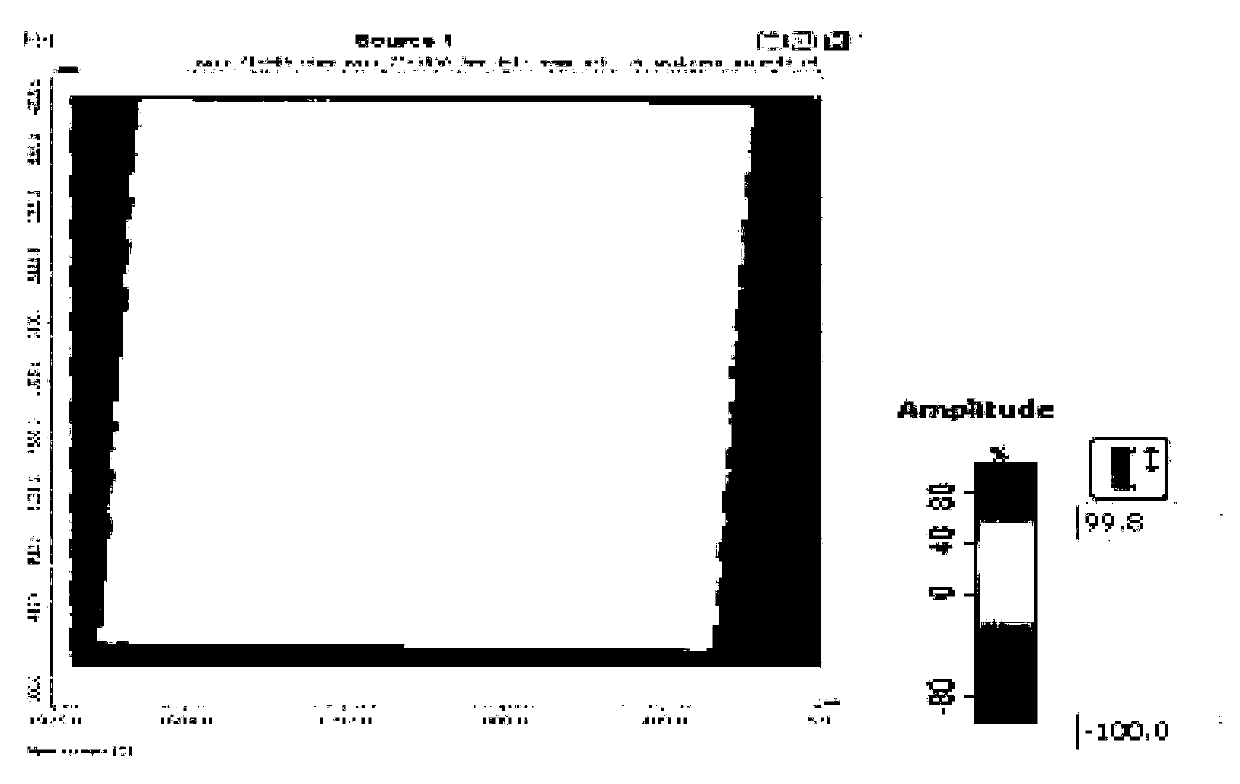

[0063] Specifically, the water-immersion phased-array ultrasonic probe (4) in the detection system uses a one-dimensional linear phased-array ultrasonic probe to balance investment cost and use efficiency. The number of phased array crystal elements of the one-dimensio...

Embodiment 3

[0083]It is necessary to use the hardware and technical methods of the phased array ultrasonic system to perform non-destructive evaluation on the 5083 brand aluminum alloy flat ingot with a specification of 600mmX2000mmX2600mm. According to the alloy phase diagram calculation and practical experience, it is speculated that the composition of the alloy, such as improper control of casting process parameters, has a greater tendency to form Alx(Mn,Fe)y aggregated coarse metal compound defects. For the non-destructive quality control of Alx(Mn,Fe)y dispersed metal compound defects, the aluminum alloy flat cast ingot water immersion ultrasonic detection system described in Example 1 is used for detection,

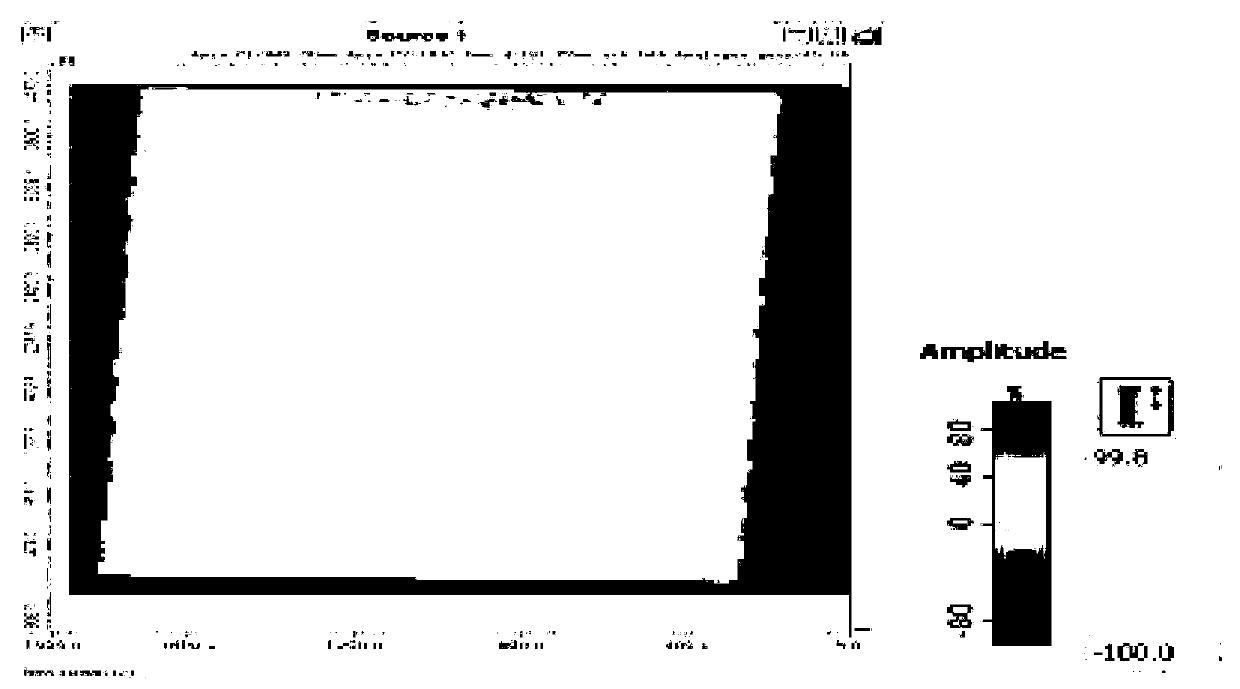

[0084] Specifically, the water-immersion phased array ultrasonic probe (4) in the detection system uses a one-dimensional linear phased array ultrasonic probe with the characteristic of "broadband and narrow pulse". The number of phased array crystal elements of the one-dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Drilling depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com