Sampling device of mixing and clarifying tank

A technology of mixing and clarifying tank and sampling device, applied in the direction of sampling device, etc., can solve the problems of sample pollution, poor durability, difficulty in sampling by manipulator operation, etc., and achieve the effect of uniform sample suction and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

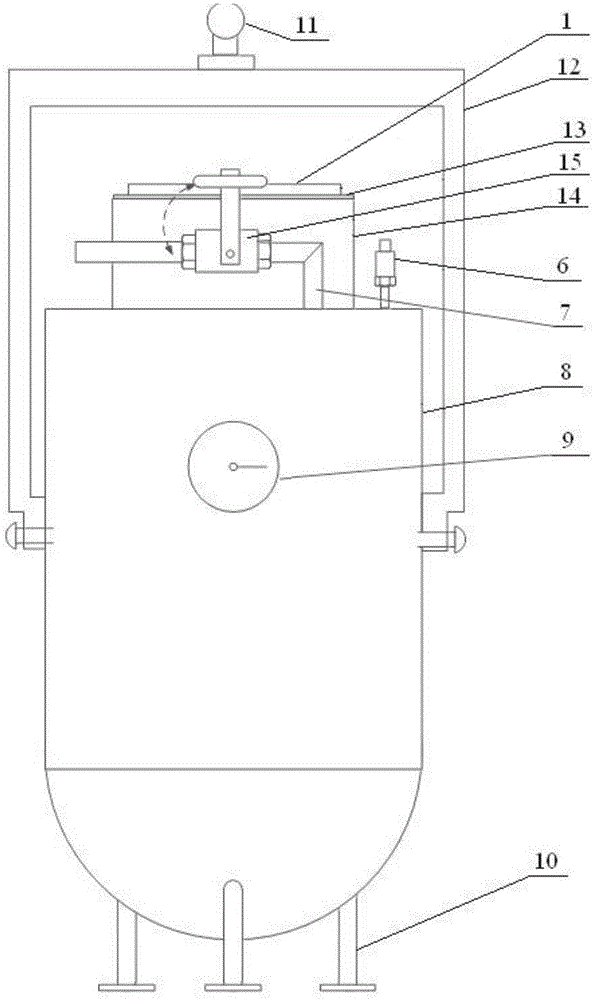

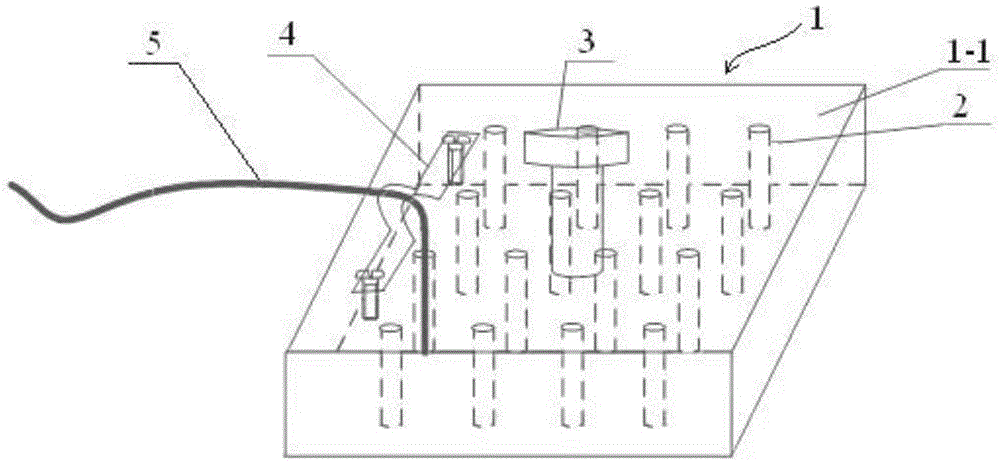

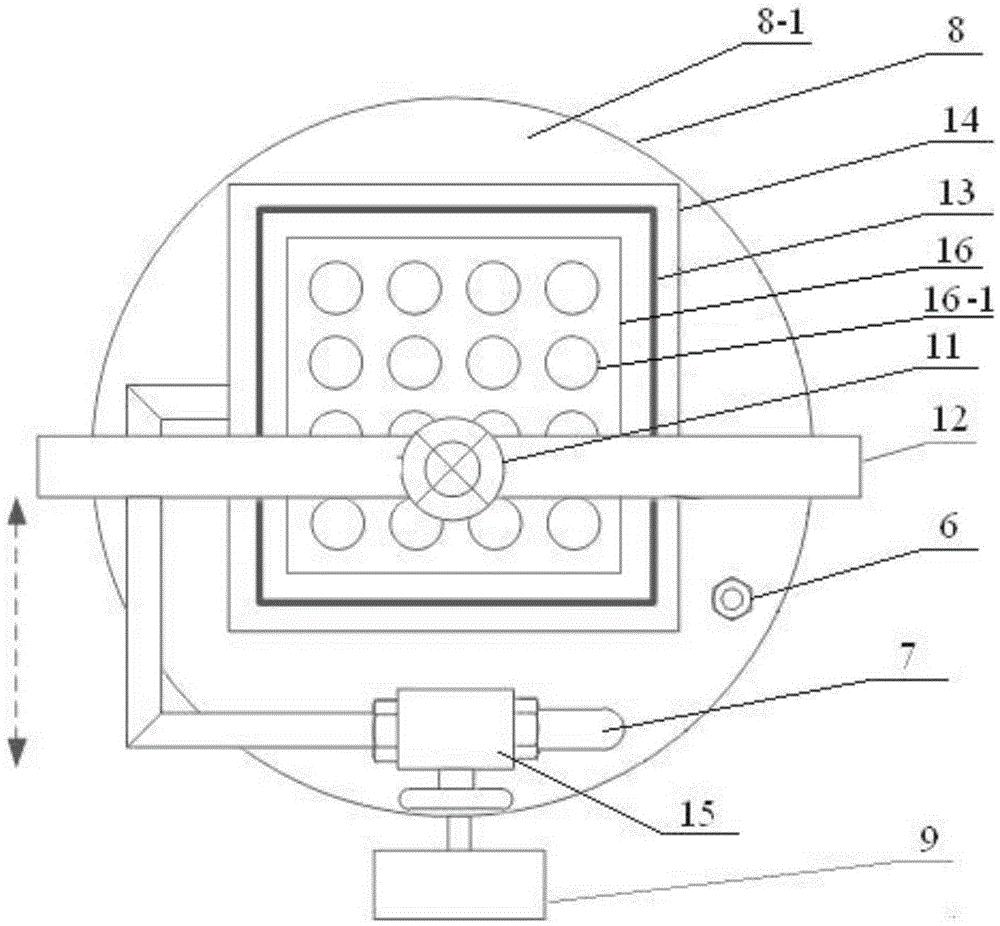

[0024] combine figure 1 , 3 It can be seen that the sampling device of the mixing and settling tank provided by the present invention comprises several sampling tubes 5 which are connected to each other at the bottom of each level of clarification chambers of the mixing and settling tank, the sampling box 1 with the bottom opening which is all connected to each other of the sampling tubes 5 (see image 3 ) and the box-shaped sampling box base 14 and vacuum buffer tank 8 of the top opening; The connecting pipe 7 with a vacuum regulating valve 15 communicates with the inner cavity of the sampling box base 14 to suck the liquid into the sampling device by means of the negative pressure generated by the vacuum buffer tank 8; there are several holes on the top plate 1-1 of the sampling box 1 , the corresponding position of each hole is respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com