Fuel rod puncture device

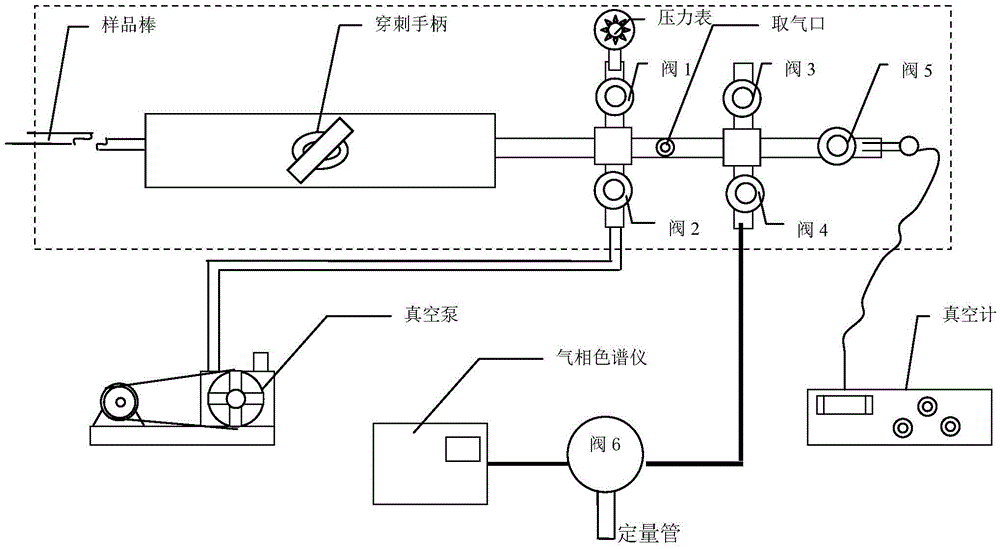

A technology of fuel rods and measuring chambers, which is applied in the field of helium volume ratio measurement in fuel rods, can solve the problems of poor sealing, low vacuum degree of puncture device, error of detection results, etc., achieves improved device vacuum degree, good sealing effect, and improved The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

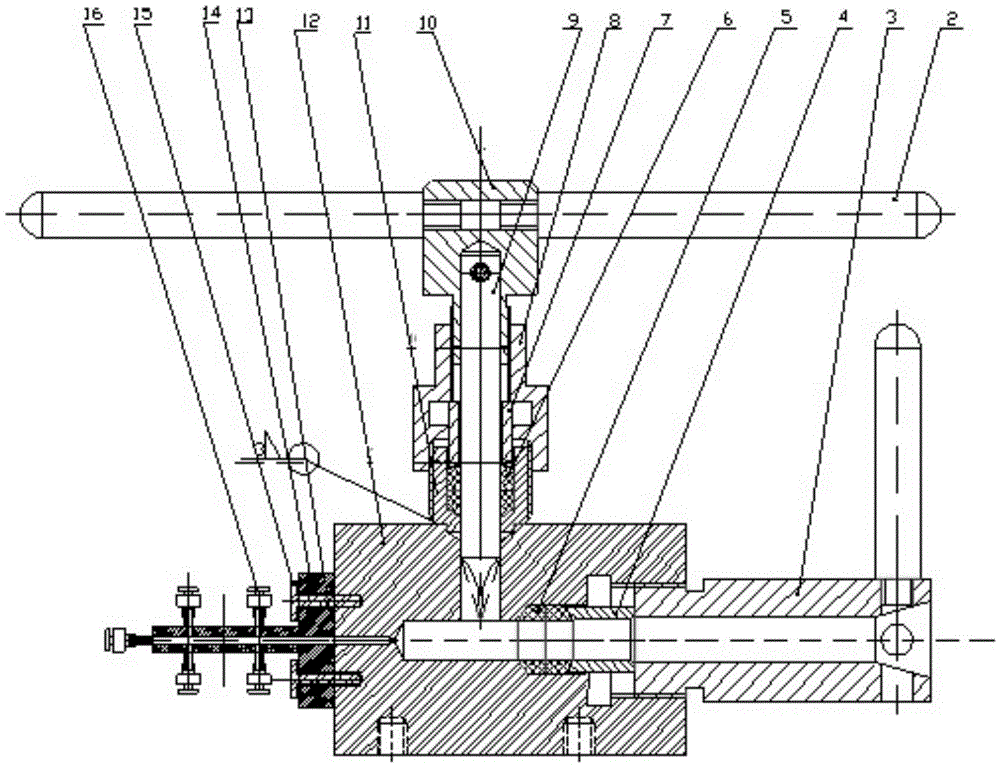

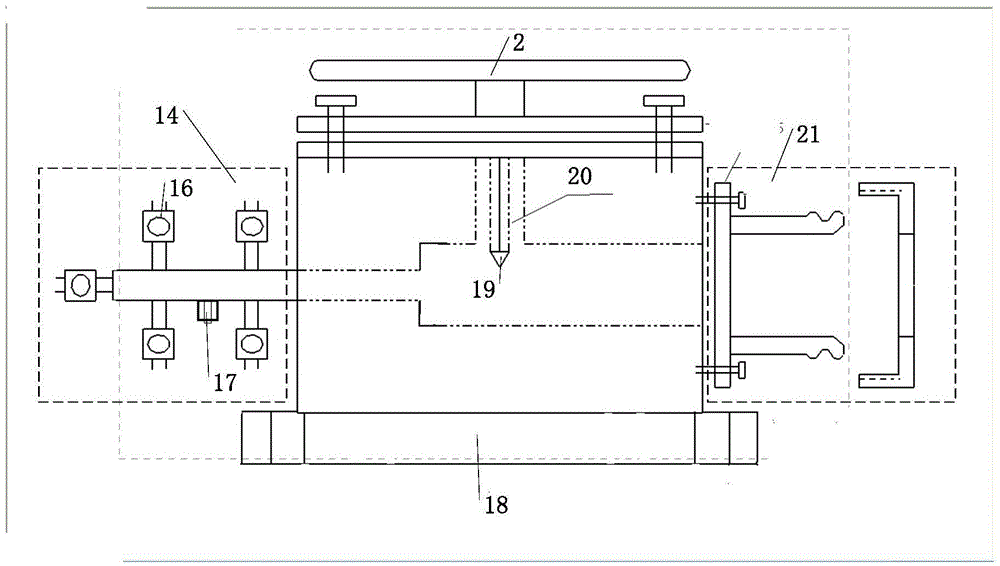

[0039] Such as image 3 As shown, a fuel rod piercing device of the present invention includes a handle 2, a sealing head 3, a first compression sleeve 4, a first sealing ring 5, a second sealing ring 6, a second compression sleeve 7, and a locking sleeve 8 , needle bar 9, rotating head 10, third sealing sleeve 11, measuring chamber 12, fourth sealing ring 13, gas source distributor 14, screw 15, valve 16 and needle 19; the right end of measuring chamber 12 is processed with three-step blind hole , where the stepped hole with the smallest inner diameter is assembled with the fuel rod, the stepped hole with the largest inner diameter is at the far right end of the measurement chamber 12, the stepped hole is processed with internal threads, the outer wall of the left section of the sealing pressure head 3 is processed with external threads, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com