Comprehensive determination method of quality characteristic of blend threshed tobacco leaves

A judging method and technology of quality characteristics, applied in the field of tobacco leaf threshing and redrying, to achieve the effect of improving work efficiency and simplifying the operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

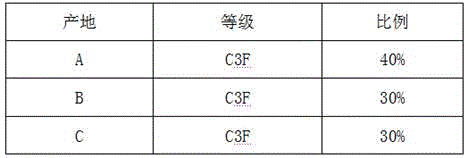

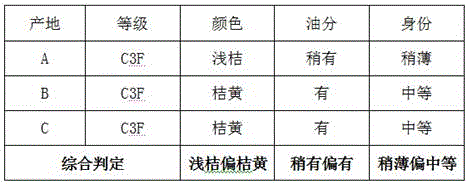

[0034] The comprehensive judgment method of formula threshing tobacco leaf quality characteristic of the present invention is carried out according to the following steps:

[0035] Step 1: Determine the indicators for judging the quality of single-grade tobacco leaves

[0036] The indicators for judging the quality of single-grade tobacco leaves are determined as three indicators: "color", "oil content" and "identity".

[0037] Step 2: Determine the different grades of single-grade tobacco leaf quality judgment indicators

[0038] The "color" index, from lemon yellow to orange, determines 3 grades, namely: lemon yellow, light orange, orange

[0039] The "oil content" indicator, from less to more, determines 4 grades, namely: less, slightly, yes, and more

[0040] The "identity" index, from thin to thick, determines 5 grades, namely: thin, slightly thin, medium, slightly thick, thick

[0041] Step 3: Assign values to different grades of single-grade tobacco leaf quality in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com