Winding structure of high-power oil-immersed high-voltage variable frequency transformer

A transformer winding, high-voltage frequency conversion technology, applied in the direction of transformer/inductor coil/winding/connection, transformer, transformer/inductor parts, etc., can solve inconvenient transportation, on-site installation, maintenance, large eddy current loss, and speed up winding Insulation aging and other problems, to avoid axial electromotive force and additional eddy current loss, reduce the height of the center of gravity, and reduce the effect of operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

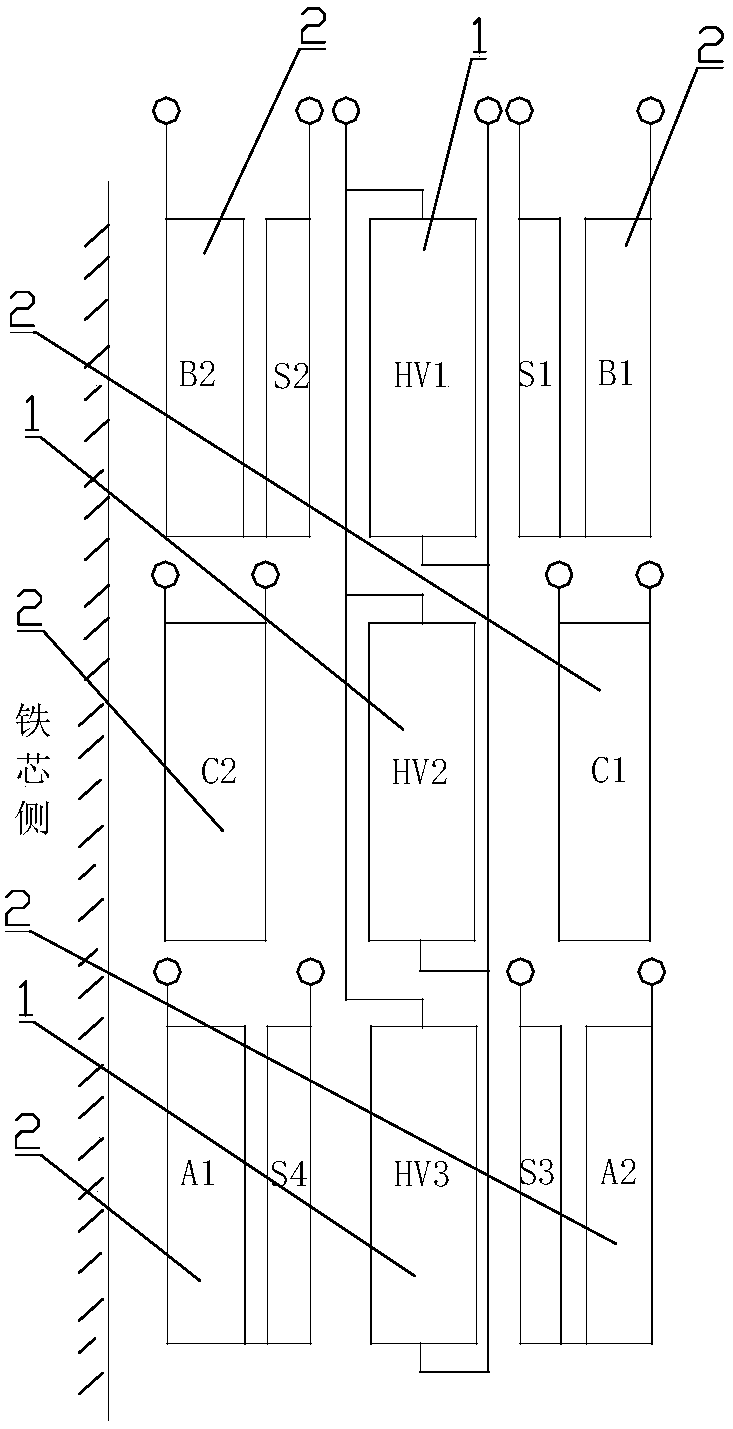

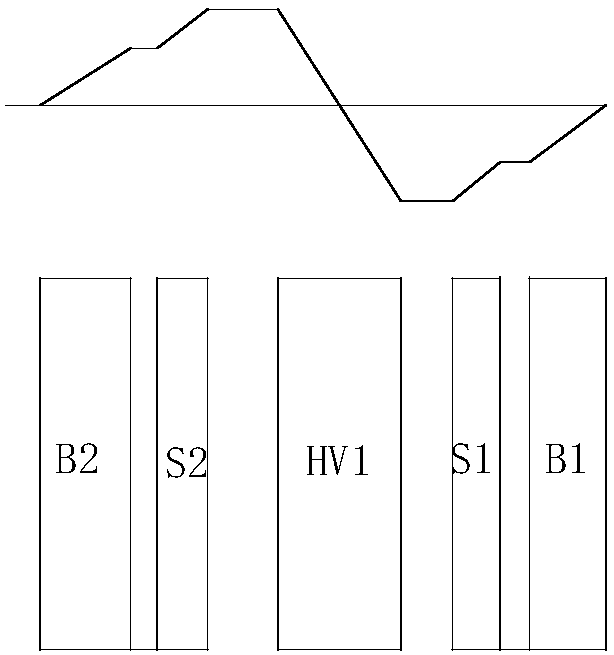

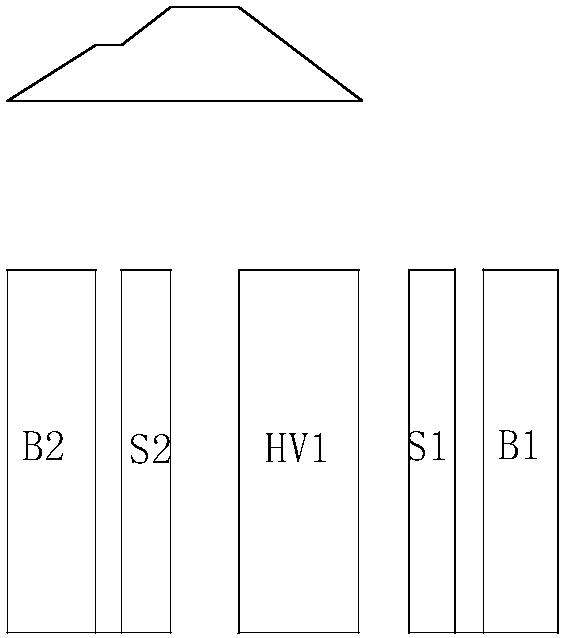

[0016] Such as figure 1 As shown, a winding structure of a high-power oil-immersed high-voltage variable frequency transformer consists of three grid-side windings 1 and six valve-side windings 2, the grid-side winding 1 and valve-side winding 2 are insulated, and the three grid-side windings 1 The capacity and voltage are equal, arranged in an axial split, connected in parallel, six valve side windings 2 The capacity and output voltage are equal, and every two valve side windings 2 form a group, a total of three groups, and the three groups of valve side winding groups are arranged axially Each valve side winding group corresponds to a grid side winding 1, and the two valve side windings 2 and the corresponding grid side winding 1 in the valve side winding group are radially split, and the two valve side winding groups in the valve side winding group Each valve-side winding 2 is located on both sides of the corresponding grid-side winding 1, and the phase shift angle differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com