Securing device for an optical body for a motor vehicle headlight

A technology of clamping device and headlight, applied in the direction of headlight, signal device, lighting device, etc., can solve problems such as loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

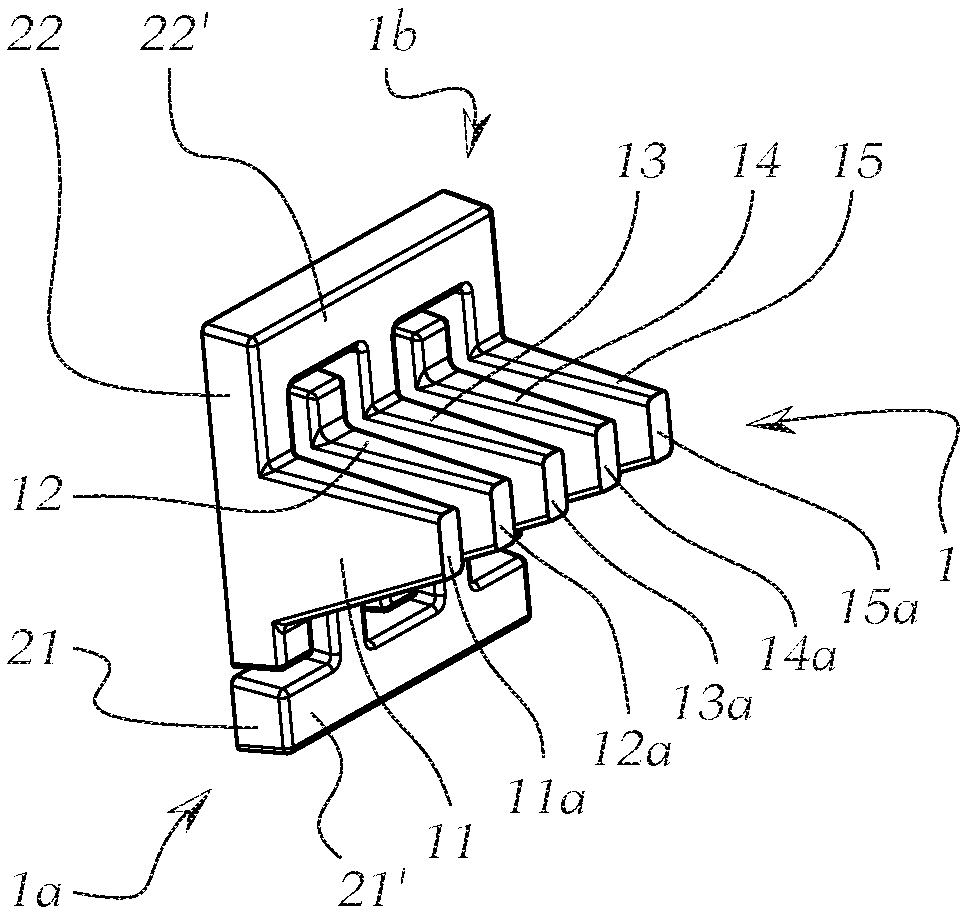

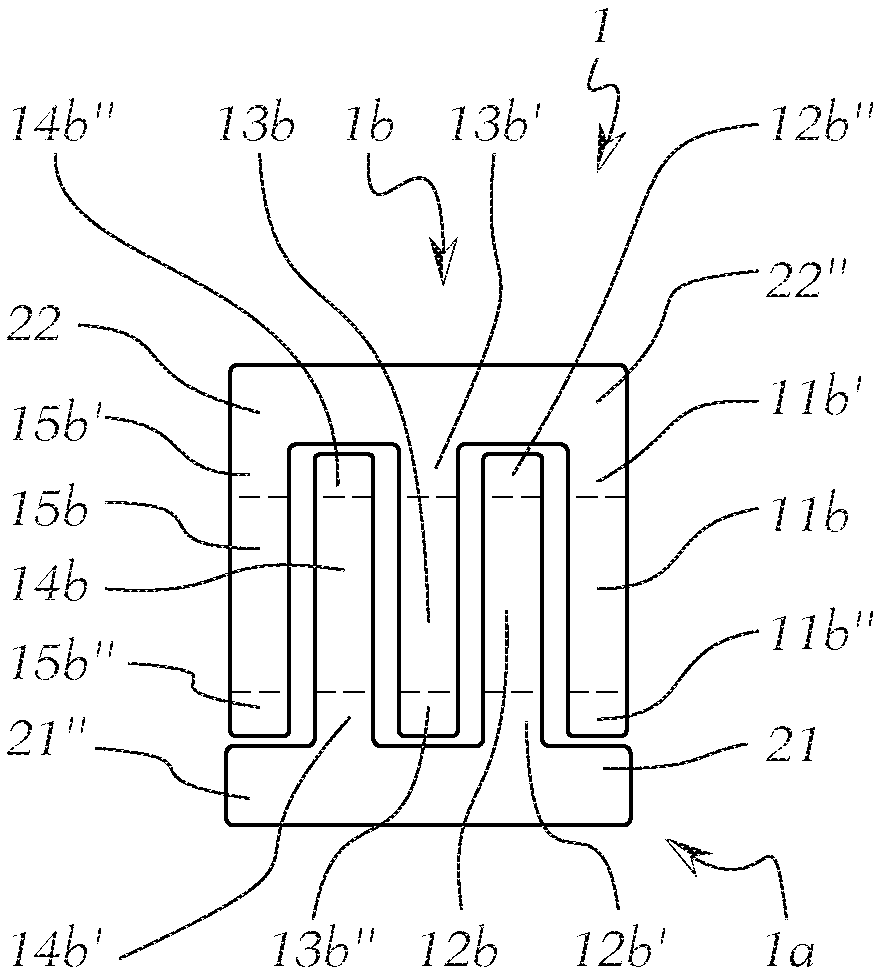

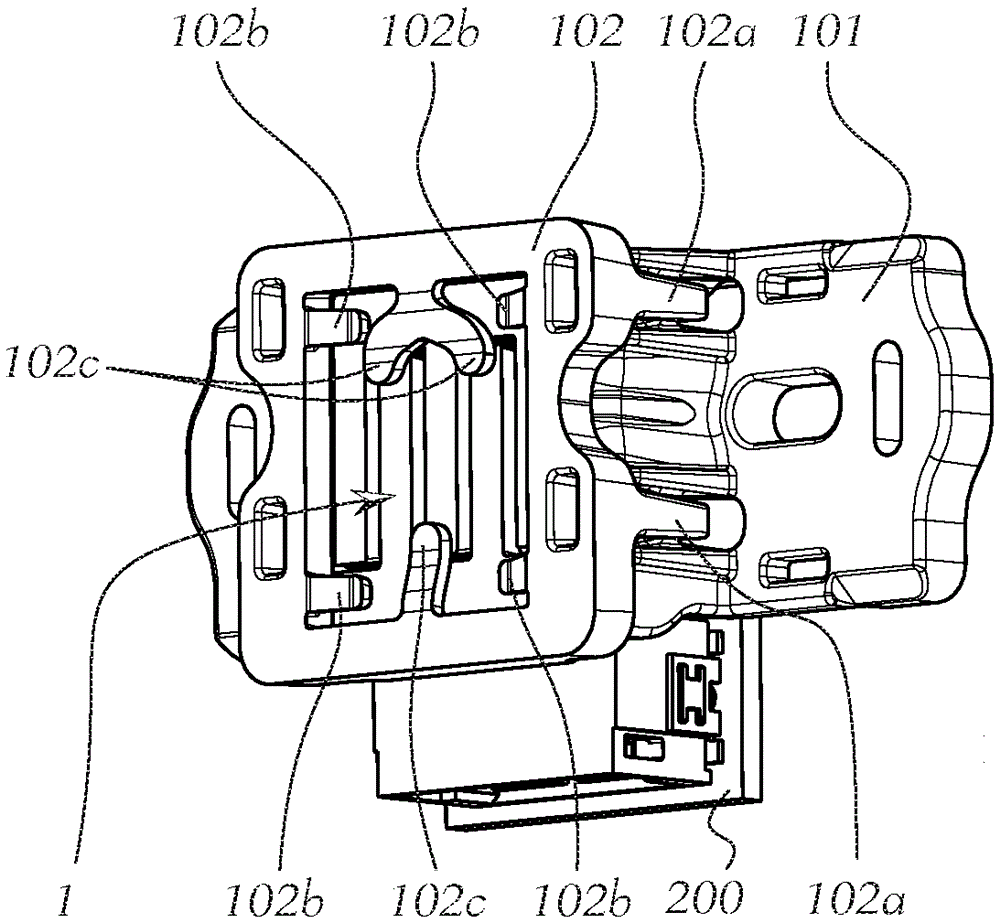

[0061] figure 1 In an assembled state and figure 2 An exploded view shows an optical tool body 1 for a motor vehicle headlight or a clamping device 100 for a light module for a motor vehicle headlight.

[0062] The optical tool body 1 can especially be figure 2 , 5 , 6 and 8 clearly show that the optical tool body includes a certain number of auxiliary optical system 11, 12, 13, 14, 15 arranged side by side, wherein each auxiliary optical system 11-15 All are composed of light guide materials and each auxiliary optical system 11-15 has a light coupling surface 11a-15a ( Figure 5 ) And optocoupler 11b-15b.

[0063] The light coupling-out surfaces 11b-15b of adjacent auxiliary optical tool systems 11-15 here have a distance of a>0 with respect to each other. As shown, the adjacent auxiliary optical tool systems are usually in their entire extended range. The interiors are separated from each other and not only in the region of the light coupling out surface, and are used to preven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com