Ophthalmic Direct Ophthalmoscope Dustproof Jacket

An ophthalmoscope and dust-proof clip technology, which is applied in the fields of ophthalmoscope, medical science, surgical equipment, etc., can solve the problems of insufficient attraction, increased workload, and inability to cooperate with inspections, so as to prevent dust from entering, improve work efficiency, and be beneficial to clinical practice. Check the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

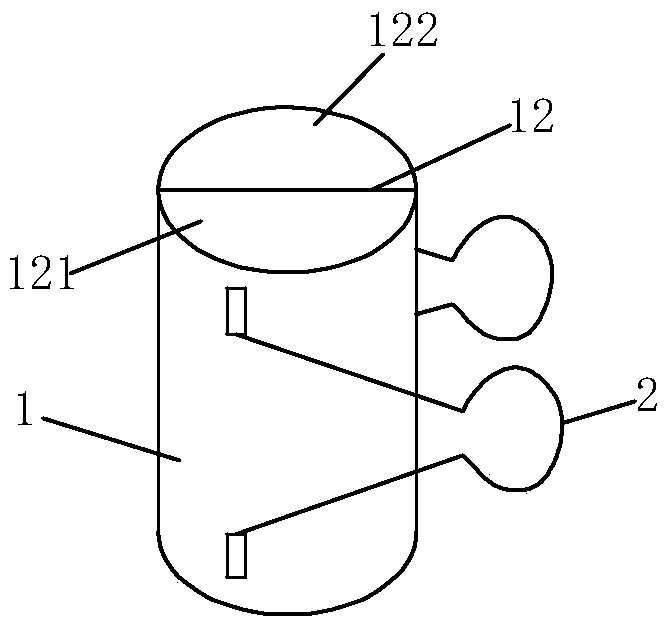

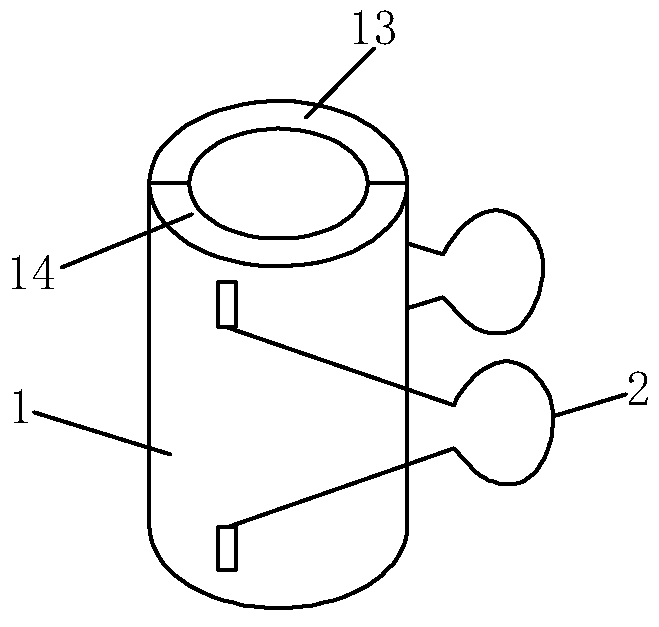

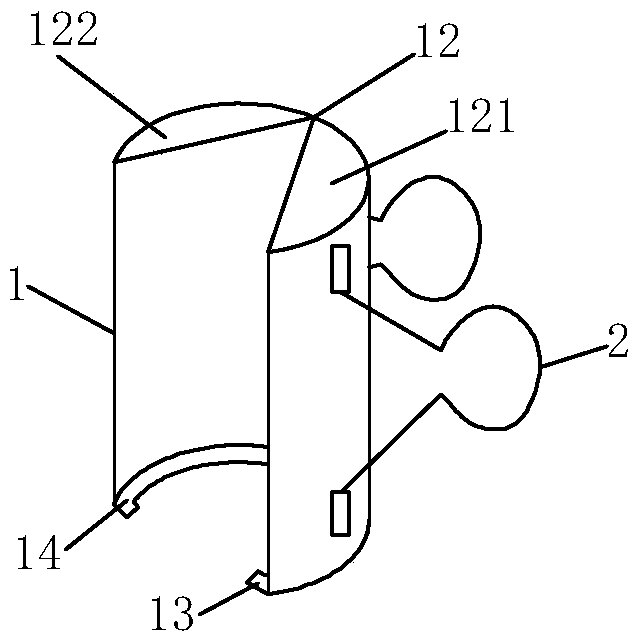

[0026] A dust-proof jacket for direct ophthalmoscope in ophthalmology, including a sleeve body 1 for covering the direct ophthalmoscope. The sleeve body 1 is a hollow elastic sleeve body with one end closed and one end open. The sleeve body 1 is provided with The inlet and outlet for direct ophthalmoscope entry and exit can be opened or closed. The sleeve body 1 is provided with a handle 2 for opening the inlet and outlet. Pressing the handle 2 by external force can open the inlet and outlet on the sleeve body 1 without external force Under action, the inlet and outlet on the sleeve 1 are in a closed state. In order to attract children's attention, the cover body 1 can be arranged in a cartoon appearance structure.

[0027] The cover body 1 includes elastic clips I111, elastic clips 113 and elastic clips II112. The elastic clips I111 and elastic clips II112 are connected by elastic clips 113 to form a hollow shell 11 with openings at both ends. , the shell 11 is an elliptical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com