Pasting device for fiber bragg grating sensor paster

A fiber grating and sticking device technology, which is applied to the surface coating device, connecting member, coating and other directions, can solve the problems of complex and changeable environment, low efficiency, small sensor patch size, etc., to achieve the patch position Accurate, easy to carry, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

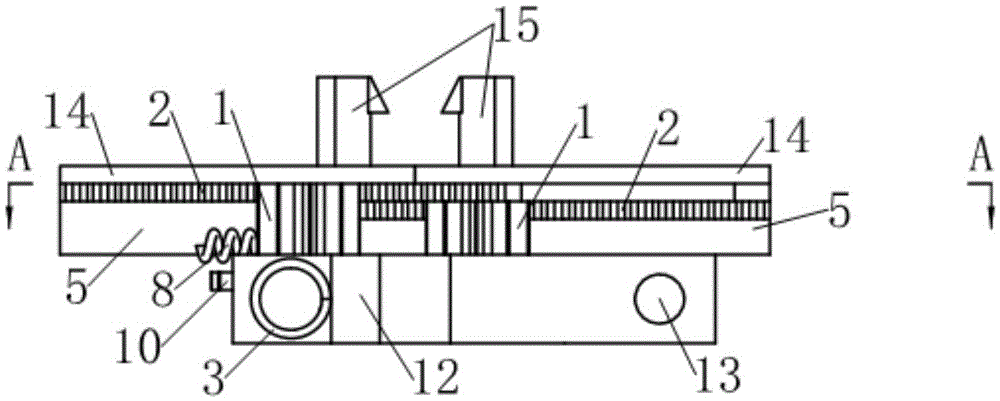

[0048] In this example, the specific implementation method of the pasting device of the present invention is described in detail by taking a king-shaped optical fiber grating sensor patch disclosed in the invention patent application with the publication number of CN104567709A as an example.

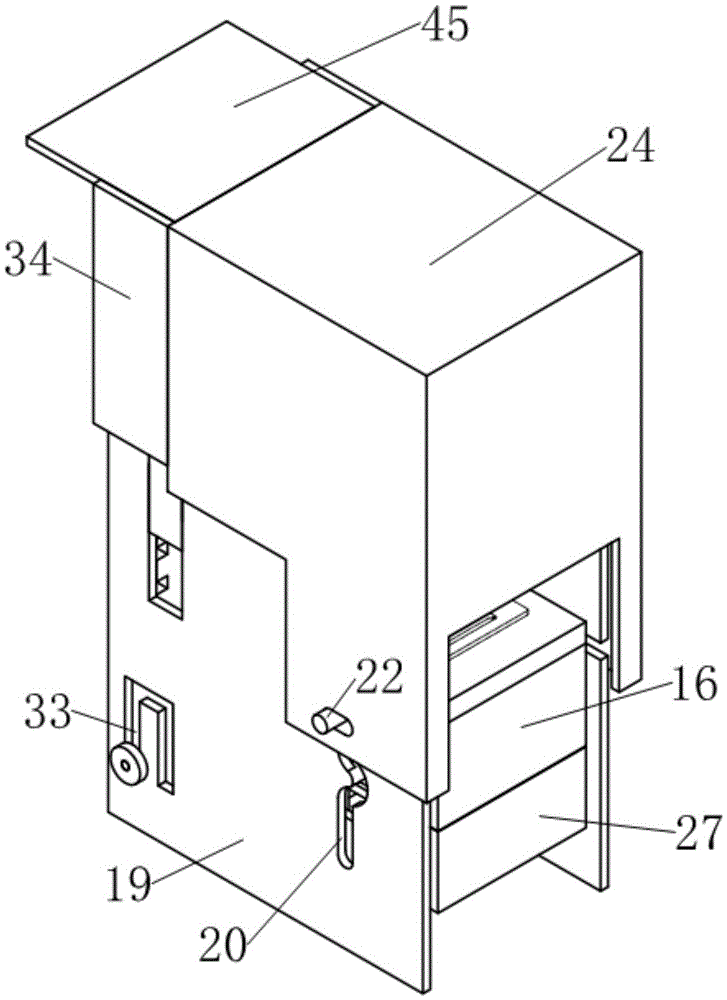

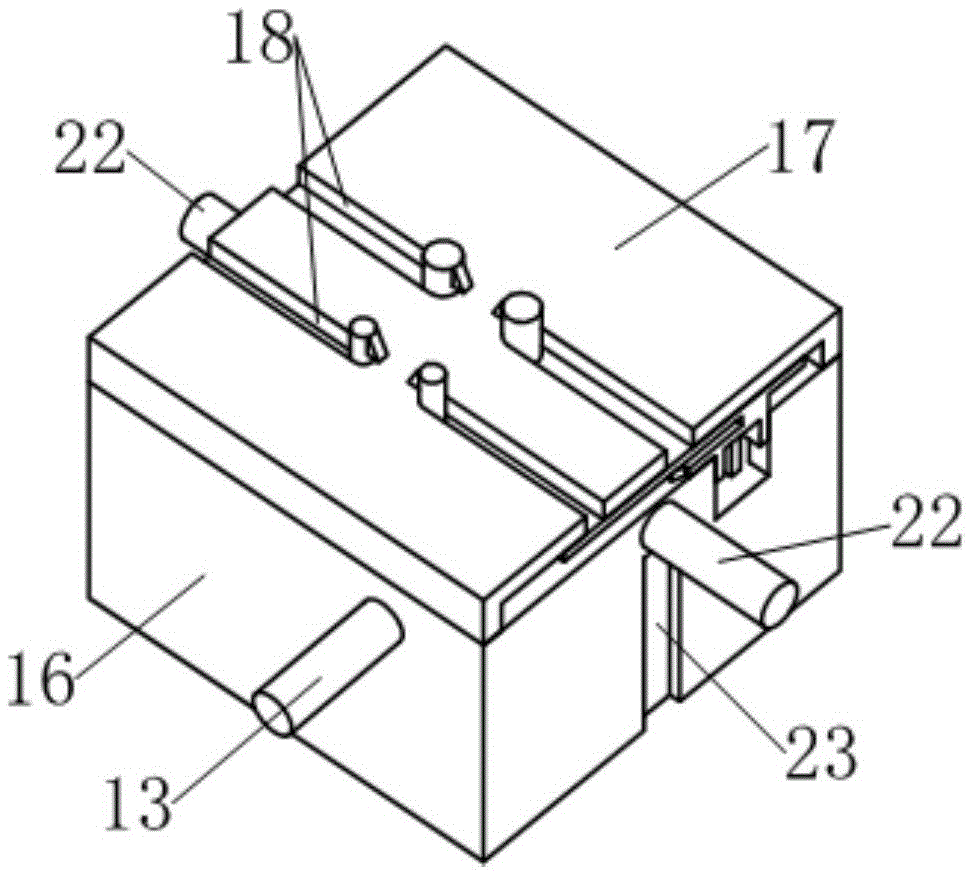

[0049] see figure 1 and combine Figure 18 , the pasting device in this example is made up of frame case 19, overturning control system and gluing control system.

[0050] Below in conjunction with accompanying drawing the structure of rack case 19 is described:

[0051] see Figure 8-10 , the rack box 19 is a cuboid with an open bottom and one side, and a vertical arcuate slot 20 is arranged at the corresponding positions of its front and back, and the arcuate slot 20 consists of two collinear straight segments up and down and a middle It is composed of an arcuate segment connecting two straight line segments; the arcuate segment of the arcuate through groove 20 is semicircular arc-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com