Computer senaille embroidery die head

A technology of drill piece embroidery and machine head, which is applied to the mechanism of embroidery machine, embroidery machine, automatically controlled embroidery machine, etc. reliability and reliability, improve work efficiency, and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further described in detail below with reference to the embodiments of the accompanying drawings.

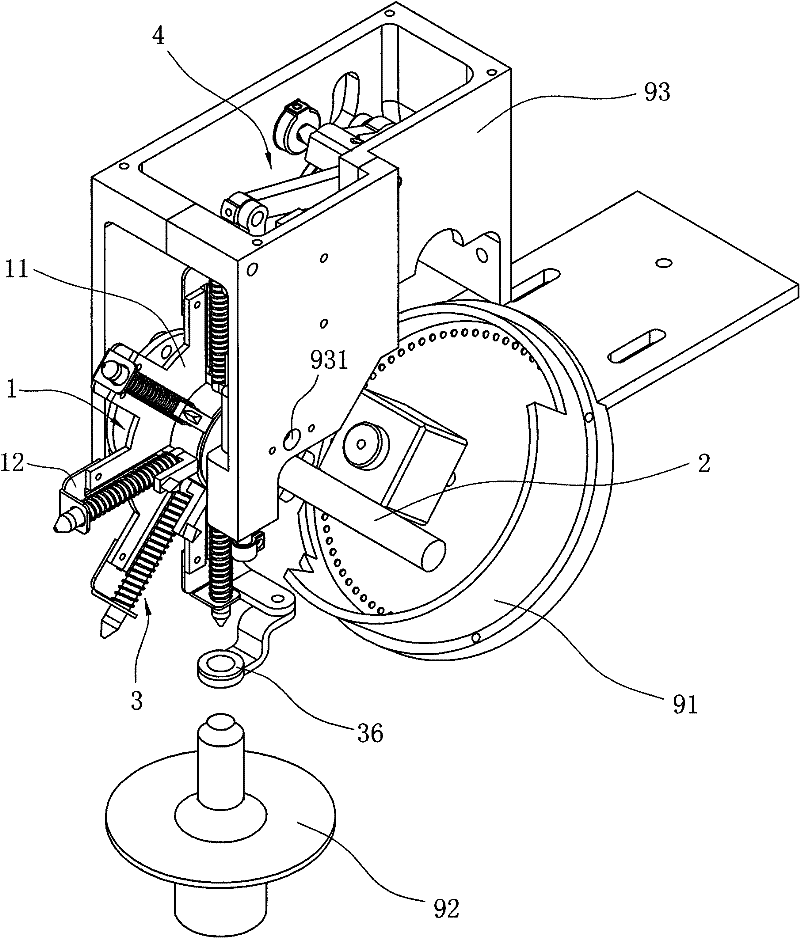

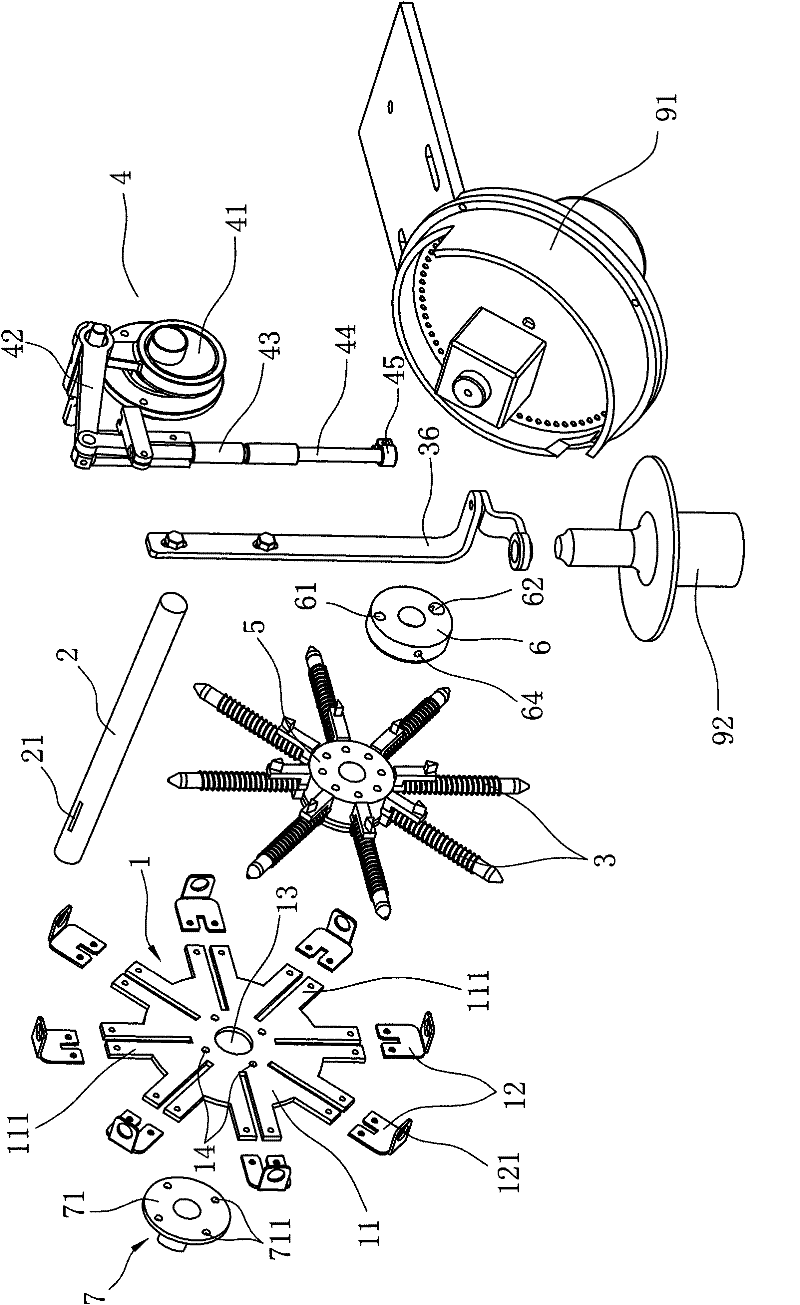

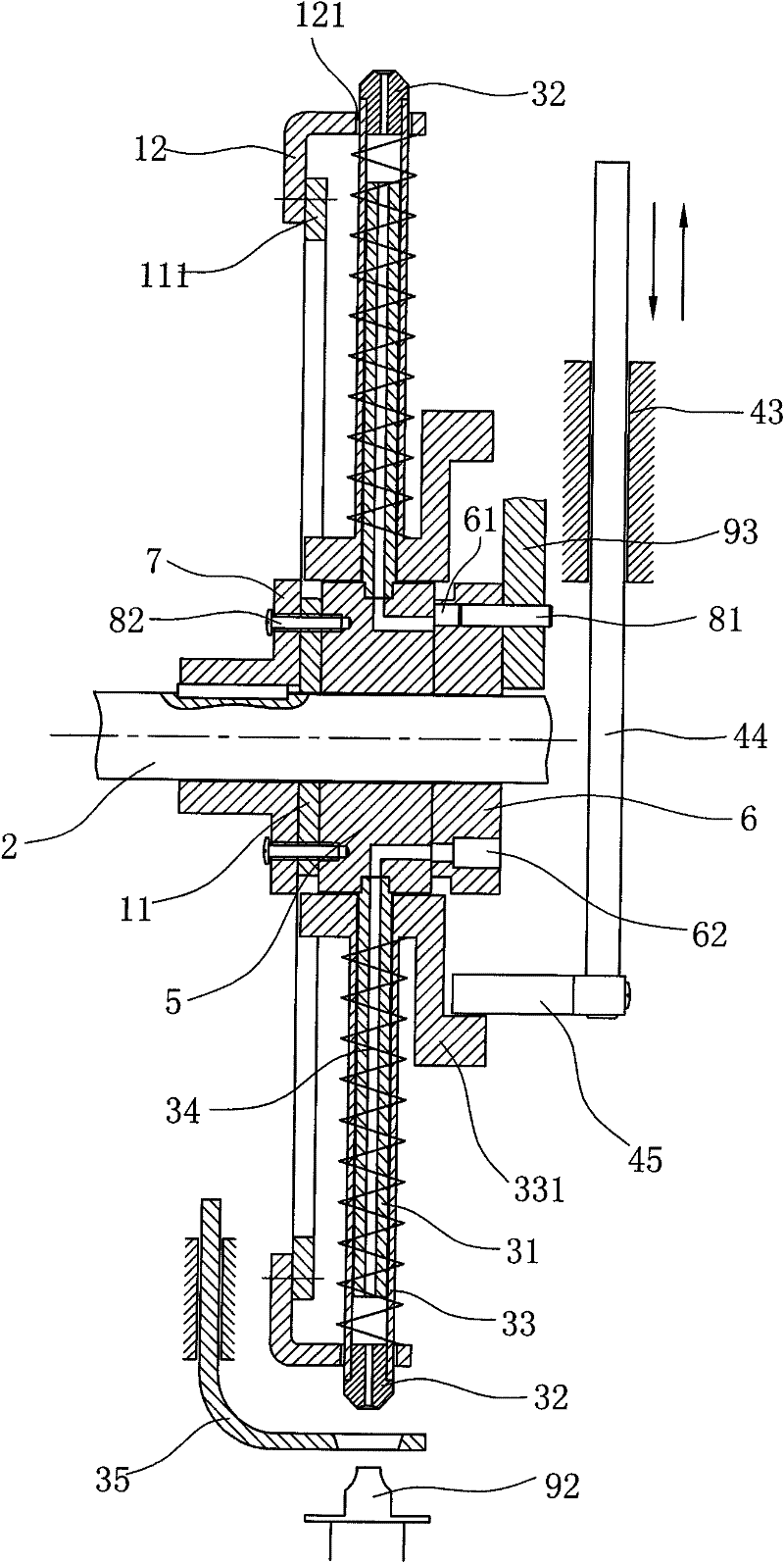

[0031] like Figure 1 to Figure 5 As shown, it is a schematic diagram of the structure of the drill head embroidery head of the present invention, and the head includes a suction claw mechanism, a pressing rod mechanism and an air supply device;

[0032] Among them, the suction claw mechanism has a rotatable claw plate 1, the claw plate 1 has a central hole 13 and is directly penetrated on the M-axis 2, and the claw plate 1 includes a main body 11 and a bracket 12 detachably connected to the main body. 11 has a circular fixed plate in the center and claw feet 111 radially arranged in a spoke shape along the circumference of the fixed plate. At the end of each claw foot 111, in order to facilitate the replacement and disassembly of the suction rod, the bracket 12 is L-shaped. Small hole 121, the vertical edge of the L-shaped bracket 12 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com