Deep hole inner wall strain gauge adhering tool for steel rolling sensor

A strain gauge and sensor technology, which is applied in the field of strain gauge patch tooling on the inner wall of deep holes, can solve the problems of difficulty in separating the strain gauge from the tooling, easy detachment from the strain gauge, and inaccurate patch positions, etc., achieving strong versatility and ease of use The effect of wide range and convenient pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

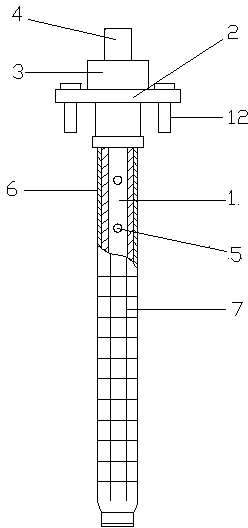

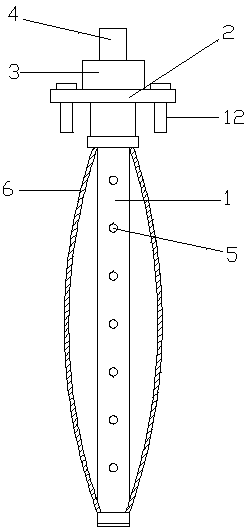

[0027] Embodiment 1: as figure 1 and figure 2 The shown one is a deep hole inner wall strain gauge patch tooling for rolling steel sensors, including a tube body 1 with one end closed, and a positioning seat 2 connected to the opening end of the tube body. The tube body 1 is a stainless steel tube, and the tube body 1 is connected to the positioning The seat 2 is threadedly connected, and a positioning hole is provided around the positioning seat 2, and a positioning pin 12 is arranged in the positioning hole; a ball valve 3 is provided on the positioning seat, and an air joint 4 is provided at the outer end of the positioning seat, and one end of the ball valve 3 is connected to the The inside of the pipe body is connected, and the other end of the ball valve 3 is connected with the gas joint 4. The side wall of the pipe body is provided with a number of vent holes 5, and the outer side of the pipe body is provided with a silicone sleeve 6. The two ends of the silicone sleev...

Embodiment 2

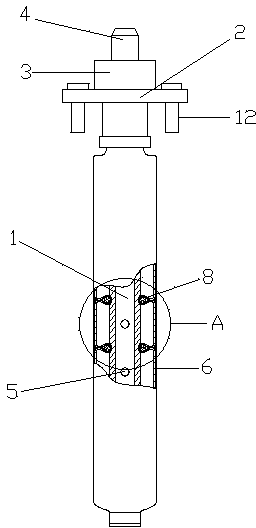

[0028] Embodiment 2: as image 3 The shown one is a deep hole inner wall strain gauge patch tooling for rolling steel sensors, including a tube body 1 with one end closed, and a positioning seat 2 connected to the opening end of the tube body. The tube body 1 is a stainless steel tube, and the tube body 1 is connected to the positioning The seat 2 is threadedly connected, and a positioning hole is provided around the positioning seat 2, and a positioning pin 12 is arranged in the positioning hole; a ball valve 3 is provided on the positioning seat, and an air joint 4 is provided at the outer end of the positioning seat, and one end of the ball valve 3 is connected to the The inside of the pipe body is connected, and the other end of the ball valve 3 is connected with the gas joint 4. The side wall of the pipe body is provided with a number of vent holes 5, and the outer side of the pipe body is provided with a silicone sleeve 6. The two ends of the silicone sleeve 6 It is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com