U-folding and feeding mechanism for rectangular enameled wire

An enameled wire and wire feeding technology, which is applied in the field of rectangular enameled wire folding U wire feeding mechanism, can solve the problems of prolonging the time of enameled wire storage process and incoherent two-step operation, and achieve the effects of facilitating follow-up work, improving continuity and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is described further as follows:

[0032] The "up" and "down" in the direction indicated in this manual are attached figure 1 Shown applies.

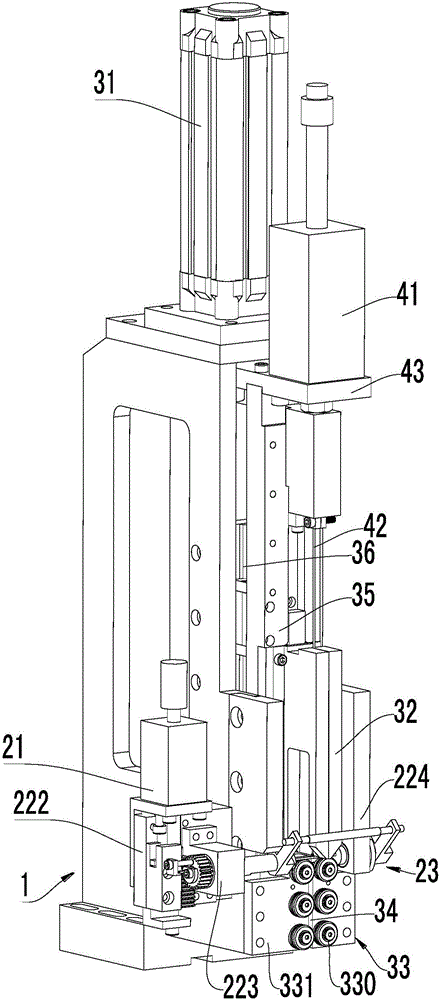

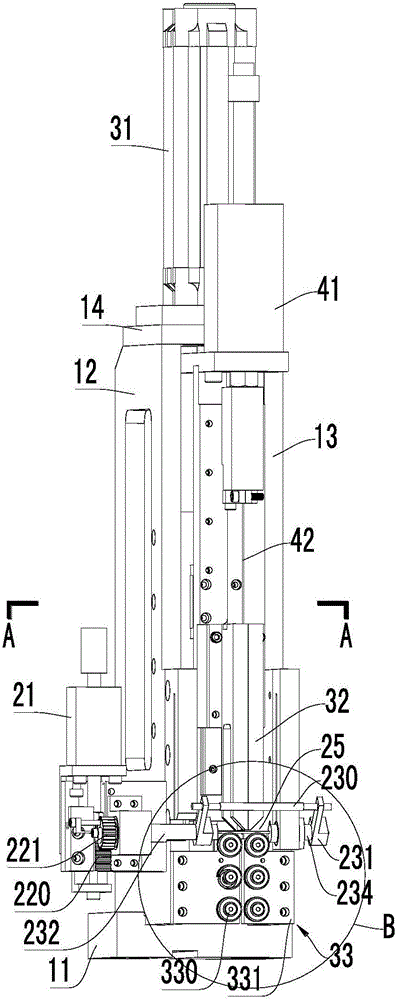

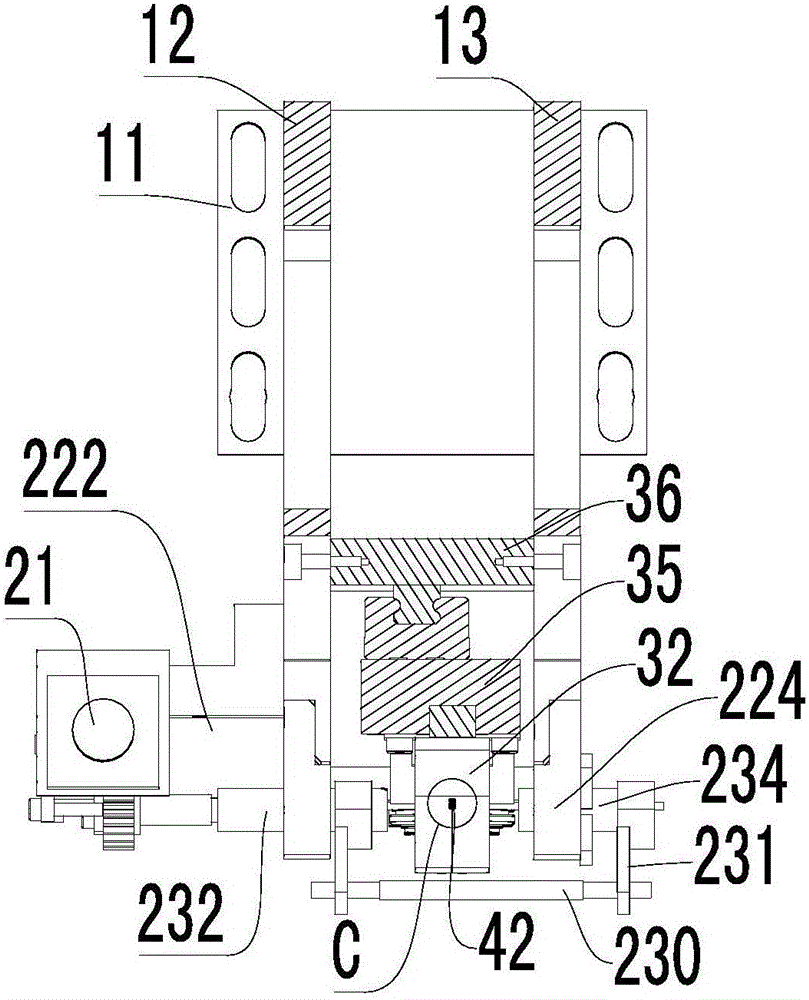

[0033] Such as Figure 1-Figure 9 As shown, the rectangular enameled wire folding U wire feeding mechanism includes a base 1, a folding U mechanism, a wire feeding mechanism and an enameled wire turning mechanism; the enameled wire turning mechanism includes a turning driving mechanism 21, a transmission mechanism and a turning member 23; the turning driving mechanism The mechanism 21 is connected to the turning part 23 through the transmission mechanism, and the turning part 23 is driven to turn over; the turning part 23 is provided with a line entry channel arranged in the horizontal direction, and a folding U operation space 25 is provided on the line entry channel; Described folding U mechanism comprises folding U cylinder 31, folding U head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com