Nozzle heat dissipation device of 3D printer

A technology of 3D printers and cooling devices, applied in the field of 3D printing, can solve the problems of other parts being dissolved and burned, affecting the molding quality of 3D printers, etc., and achieve the effect of reducing vibration, reducing speed and enhancing heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

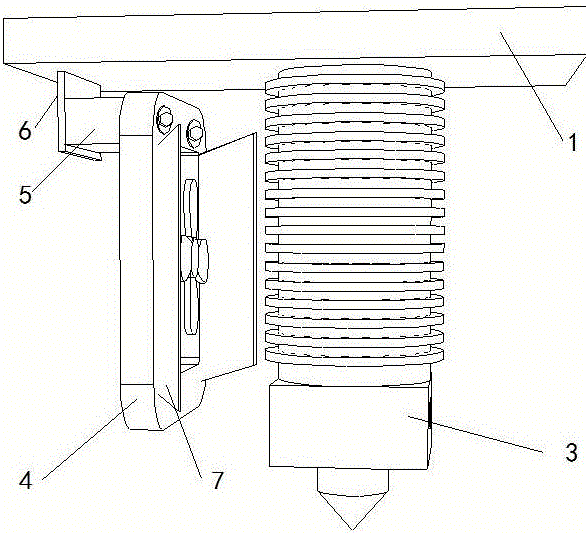

[0010] Such as figure 1 As shown, a nozzle cooling device of a 3D printer includes a cooling fan 4; the cooling fan 4 is arranged on the outside of the nozzle 3 fixedly connected to the support 1 of the 3D printer, and the nozzle cooling device of the 3D printer also includes a connecting plate 6 , an elastic rubber block 5 and two wind gathering plates 7, the connecting plate 6 is vertically arranged, the upper end of the connecting plate 6 is fixedly connected with the support 1 of the 3D printer, and the elastic rubber block 5 is arranged on the cooling fan 4 and the connecting plate 6 Between, the heat dissipation fan 4, the elastic rubber block 5 and the connecting plate 6 are connected by bolts, two wind gathering plates 7 are fixed on both sides of the air outlet of the heat dissipation fan 4, and the two wind gathering plates 7 are all inclined Set, the included angle between two wind gathering boards 7 is an acute angle.

[0011] The air outlet of the cooling fan 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com