On-line production method and on-line production device for coiled material/plate glass composite board

A flat glass, production method technology, applied in chemical instruments and methods, layered products, lamination devices, etc., can solve the problems of high cost, heavy quality, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

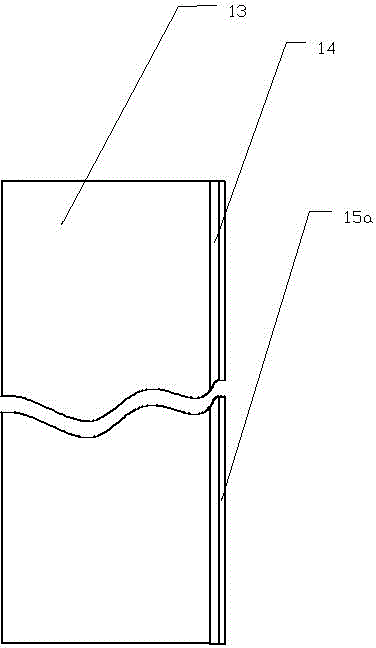

[0022] figure 1 In the process, the glass plate (13) and the silk fabric (15) are compounded together by UV glue (14), the UV glue solution penetrates the silk fabric, and the silk fabric is submerged and fixed in the glue layer.

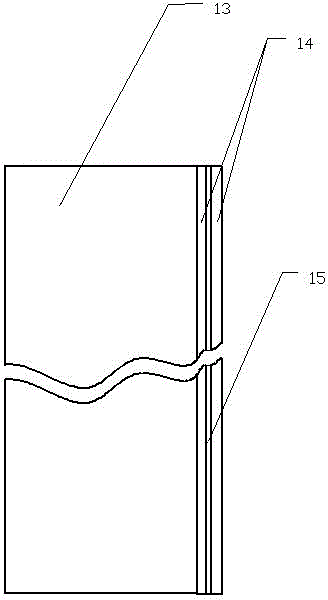

[0023] figure 2 In the process, the glass plate (13) is combined with other rolls (15a) except silk fabric by UV glue (14).

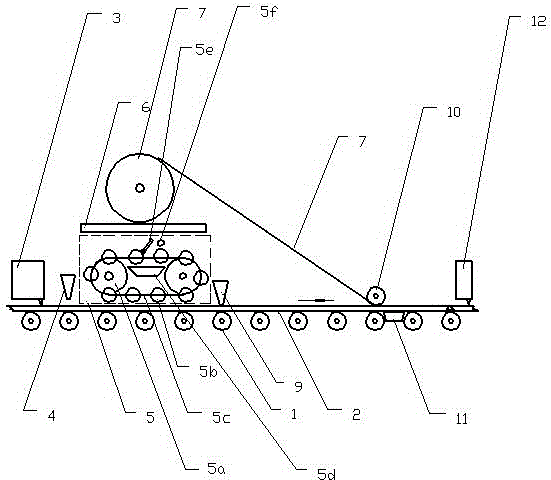

[0024] image 3 It describes a composite process of a transparent plastic film roll and an online glass plate (2). First, use the cross-cutting machine (3) in the traditional mechanical knife wheel cutting equipment and the slitting machine (16) in the traditional mechanical knife wheel cutting equipment to scratch the surface of the glass plate, but do not break it; The cleaning equipment (4) cleans the floating dust on the upper surface of the glass plate (2) running online, and the finer dust is removed by the cleaning and purification equipment (5) on the surface of the glass plate; the UV adhesive tape equipment (9) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com