Intelligent traction system of self-locking winch

A winch, self-locking technology, applied in the direction of the hoisting device, the spring mechanism, etc., can solve the problems of energy waste, accidents, affecting the alignment accuracy, etc., to protect the air environment, improve service life, and reduce maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

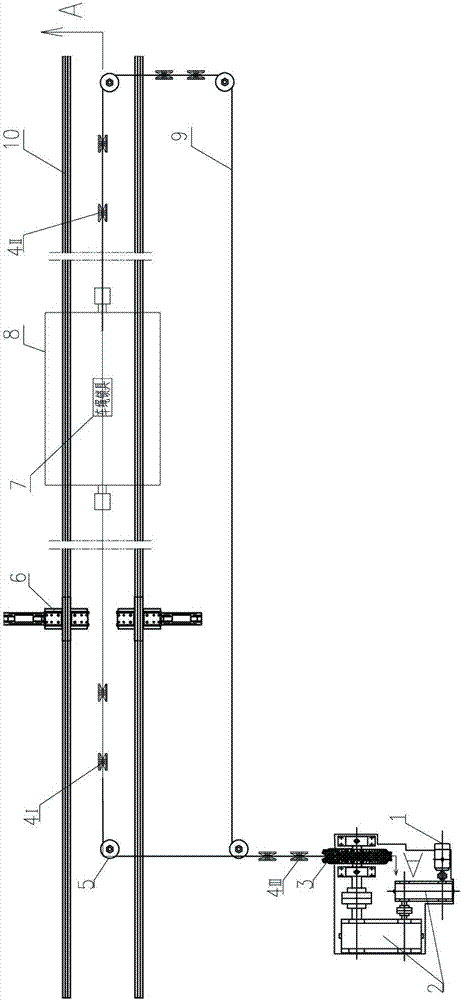

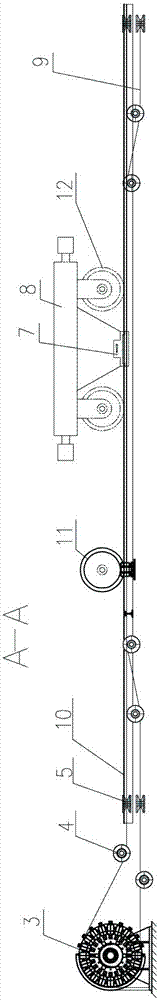

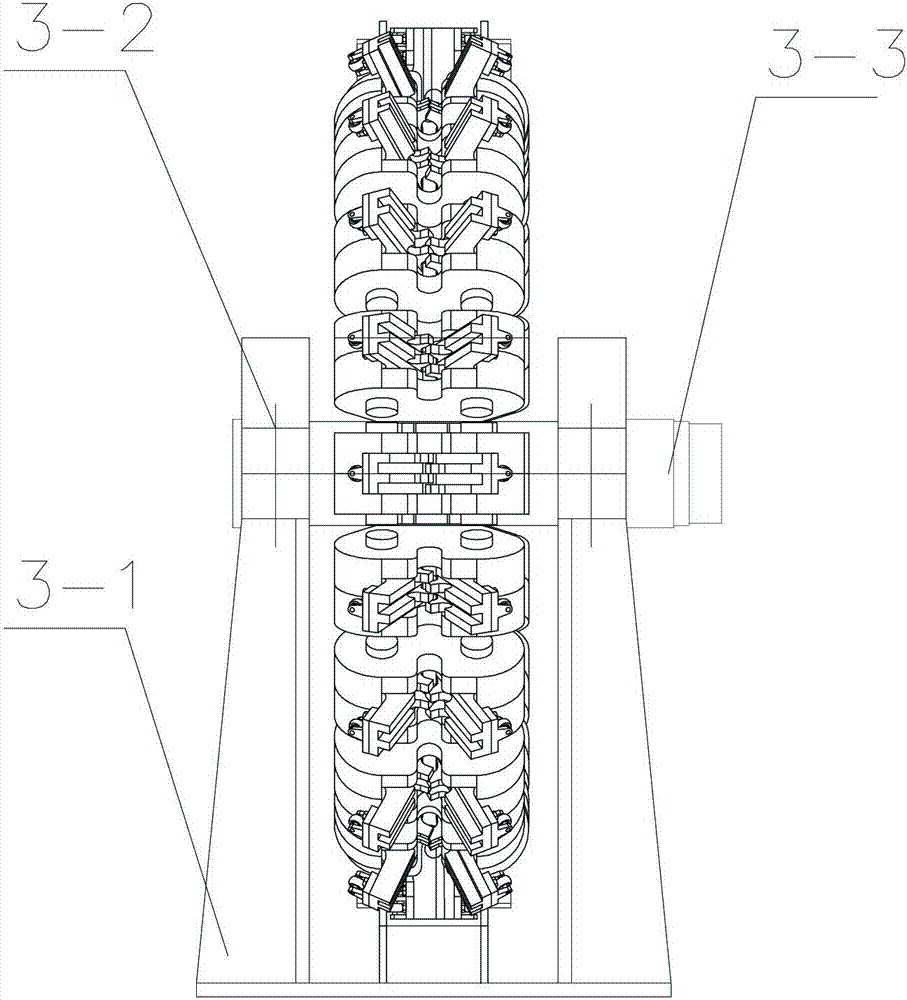

[0030] Such as Figure 1-Figure 2 As shown, a self-locking winch intelligent traction system of the present invention is characterized in that: it includes a driving mechanism composed of a hoisting motor 1 and a secondary reducer 2 arranged on the end side of the rail 10, through a coupling and a secondary reducer The self-locking winch 3 connected with the machine 2, the vertical guide wheel 4, the horizontal guide wheel 5, the traction steel rope 9, the hydraulic brake 6, the car rope lock 7 and the walk-in tractor 8, the hydraulic brake 6 is set On both sides of the rail 10, the walk-in tractor 8 is arranged on the rail 10, and the vertical guide pulley 4 is arranged on the lower part of the rail by two vertical guide pulleys 4I arranged at the center head of the lower part of the rail. Two vertical guide pulleys 4II at the center tail and two horizontal vertical guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com