Method and device for acid washing of alkylation reaction effluent

A technology of alkylation reaction and effluent, which is applied in the field of alkylation waste acid treatment, can solve the problems of removing sulfuric acid and sulfuric acid ester, corrosion of downstream equipment, failure to fully utilize sulfuric acid, etc., to improve utilization efficiency and promote separation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

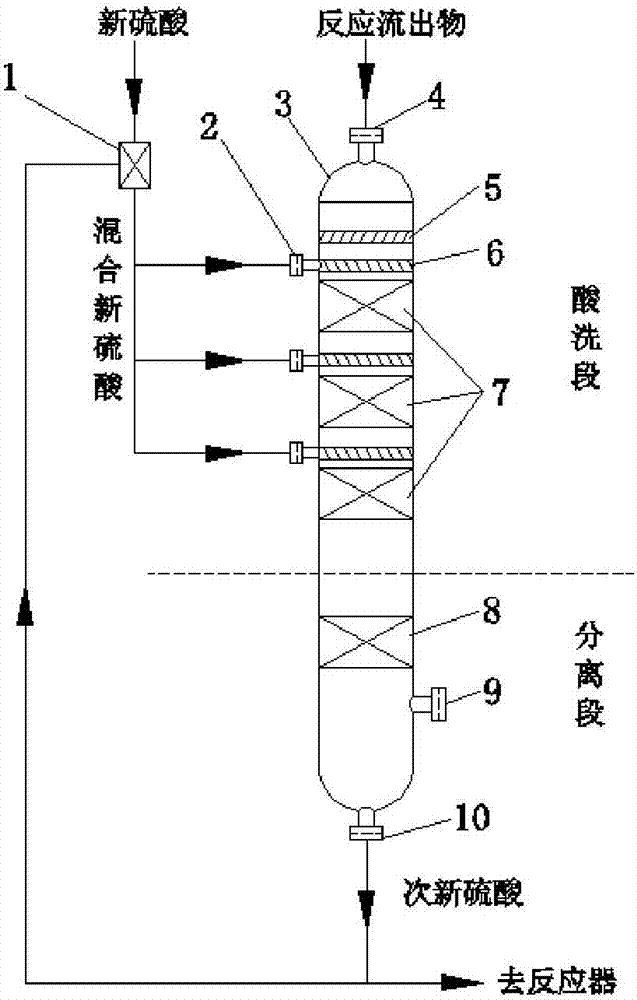

[0063] according to figure 1 The process of pickling the alkylation reaction effluent shown is carried out, wherein the microchannel screen is randomly woven with a 316L wire mesh with a diameter of 100 μm, its thickness is 400 mm, and the porosity is 70%. The distance between each section of screen is 300mm, and the top of each section of screen is 80mm away from the mixed new sulfuric acid liquid distributor; 2 sections of separation packing are used, and the distance between each section of separation packing is 350mm. The porosity is 75%.

[0064] The main parameters of the pickling process of the alkylation reaction effluent: the working pressure of the pickling tank is 0.55MPa; the concentration of new sulfuric acid is 98% (WT), and the flow rate is 2.5m 3 / h; Alkylation reaction effluent treatment capacity is 100m 3 / h, its sulfuric acid content is 2000ppm, and total sulfur content is 990ppm.

[0065] Experimental results:

[0066] After pickling by the method and d...

Embodiment 2

[0068] according to figure 1 The process of pickling the alkylation reaction effluent shown is carried out, wherein the microchannel screen is randomly woven with 80 μm metal fiber material, the thickness of the screen is 300 mm, and the porosity is 70%. Three sections of screen are set, The distance between each section of wire mesh is 320mm, and the distance between the top of each section of wire mesh is 70mm from the mixed new sulfuric acid liquid distributor; the separation section of the pickling tank adopts 2 sections of separation packing, and the distance between each section of separation packing is 300mm. The porosity of the filler is 80%.

[0069] The main parameters of the pickling process of the alkylation reaction effluent: the working pressure of the pickling tank is 0.55MPa; the concentration of new sulfuric acid is 98% (WT), and the flow rate is 20m 3 / h; Alkylation reaction effluent treatment capacity is 600m 3 / h, its sulfuric acid content is 1800ppm, and...

Embodiment 3

[0073] according to figure 1 The process of pickling the alkylation reaction effluent shown is carried out, wherein the microchannel screen is woven with 60 μm fiber material, its thickness is 400 mm, and the porosity is 55%. Three sections of screen are set, and each section of screen is The distance between them is 300mm, and the top of each section of wire mesh is 80mm away from the mixed new sulfuric acid liquid distributor; 1 section of separation packing is used, the porosity of the separation packing is 75%, the thickness is 250mm, and 316L metal fiber and polytetrafluoroethylene fiber are used The material is woven.

[0074] The main parameters of the pickling process of the alkylation reaction effluent: the working pressure of the pickling tank is 0.55MPa; the new sulfuric acid concentration is 98% (WT), and the flow rate is 30m 3 / h; Alkylation reaction effluent treatment capacity is 1000m 3 / h, its sulfuric acid content is 2000ppm, and total sulfur content is 870p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com