Wastewater flushing type closestool

A technology for toilets and waste water, which is applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc. It can solve problems such as environmental pollution, easy wear and tear of parts, and short service life, and achieves convenient and simple use, good sealing performance, and easy to use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are preferred embodiments of the present invention, but they do not limit the protection scope of the present invention.

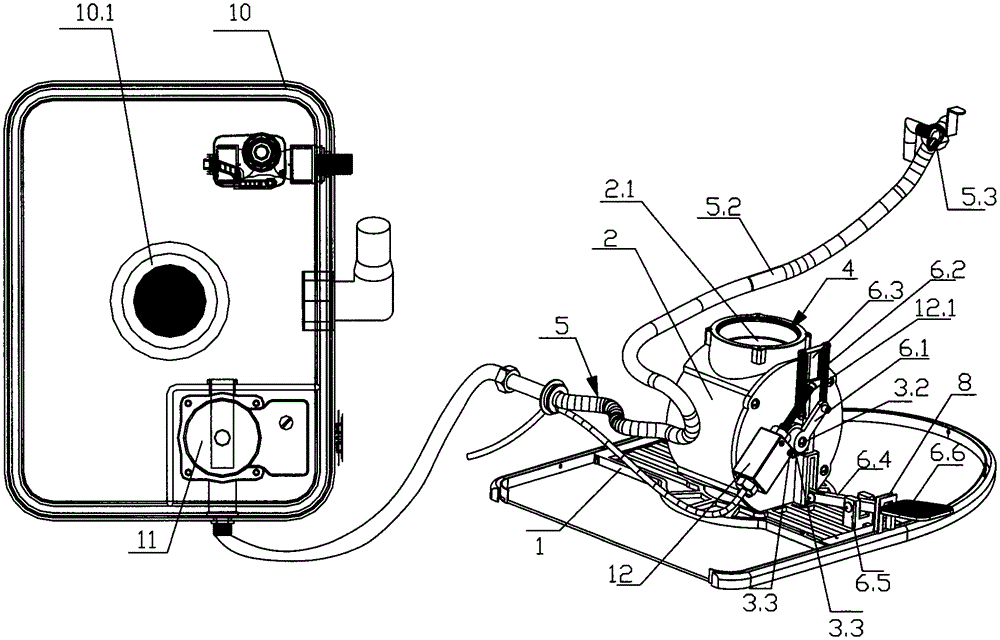

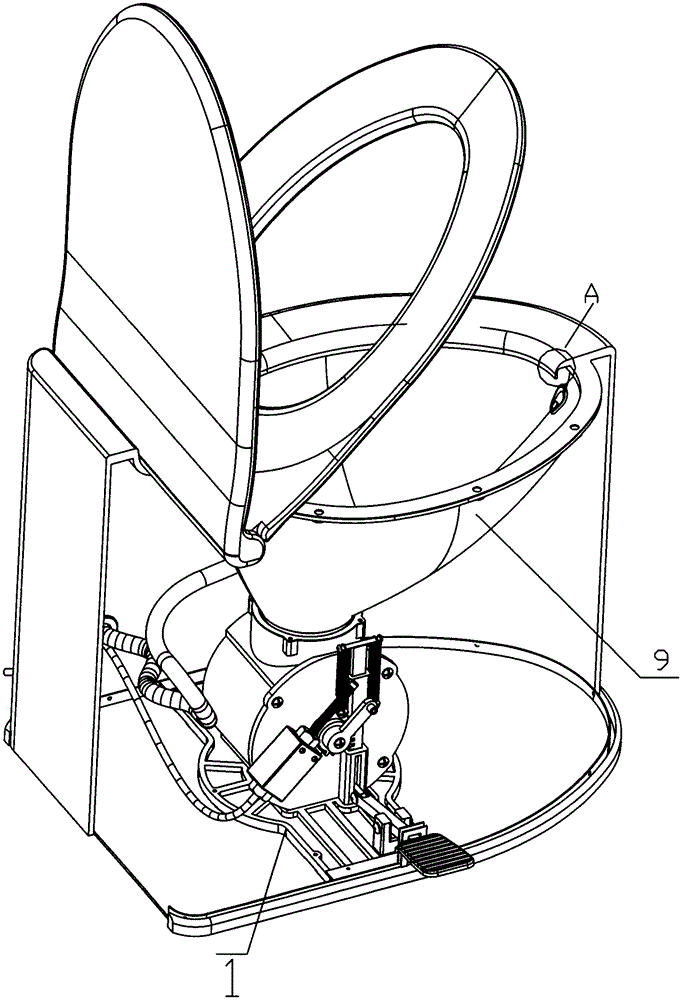

[0026] refer to Figure 1-Figure 8 A waste water flushing toilet is shown, comprising a water storage tank 10, a liquid suction pump 11, an electric control assembly 12, a toilet body 9 and a discharge mechanism, the discharge mechanism communicates with the bottom of the toilet body 9, and the liquid suction pump 11 communicates with the water storage tank 10 and the The toilet body 9, the electric control component 12 controls the operation of the suction pump 11, and the excretion mechanism controls the operation of the electric control component 12.

[0027] The discharge mechanism includes a mounting plate 1, the mounting plate 1 is provided with a valve seat 2, the valve seat 2 is provided with an upper through-hole 2.1 and a lower through-hole 2.2 that penetrate up and down, and the mounting plate 1 is designed to be through at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com