Drive mechanism for adjusting motor vehicle components

A technology for driving mechanisms and motor vehicles, which is applied in the directions of power control mechanisms, wing leaf control mechanisms, wing leaf components, etc., can solve problems such as increased conversion noise and wear, insufficient connection, and difficult process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

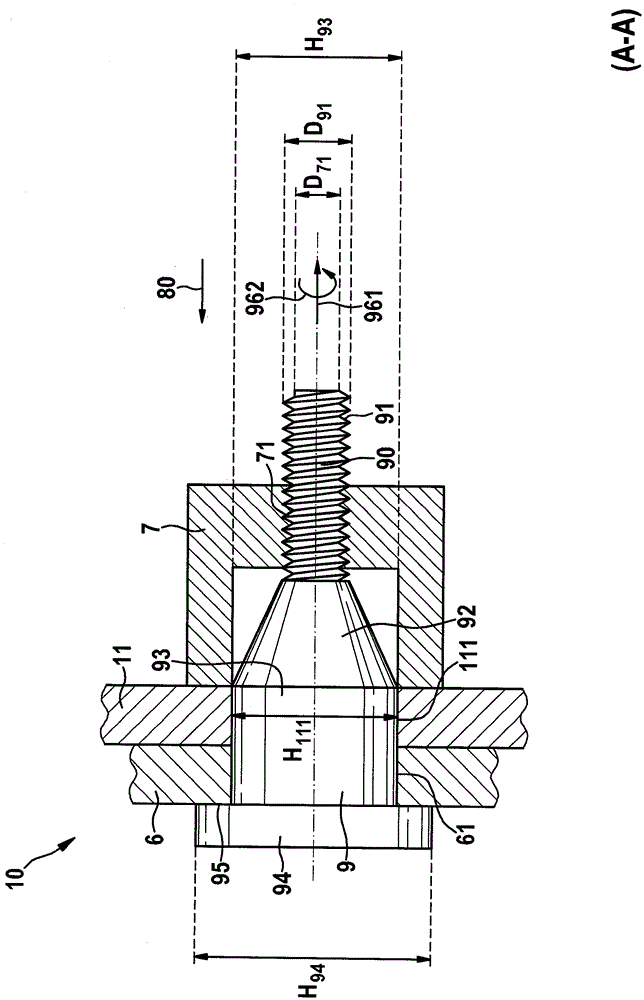

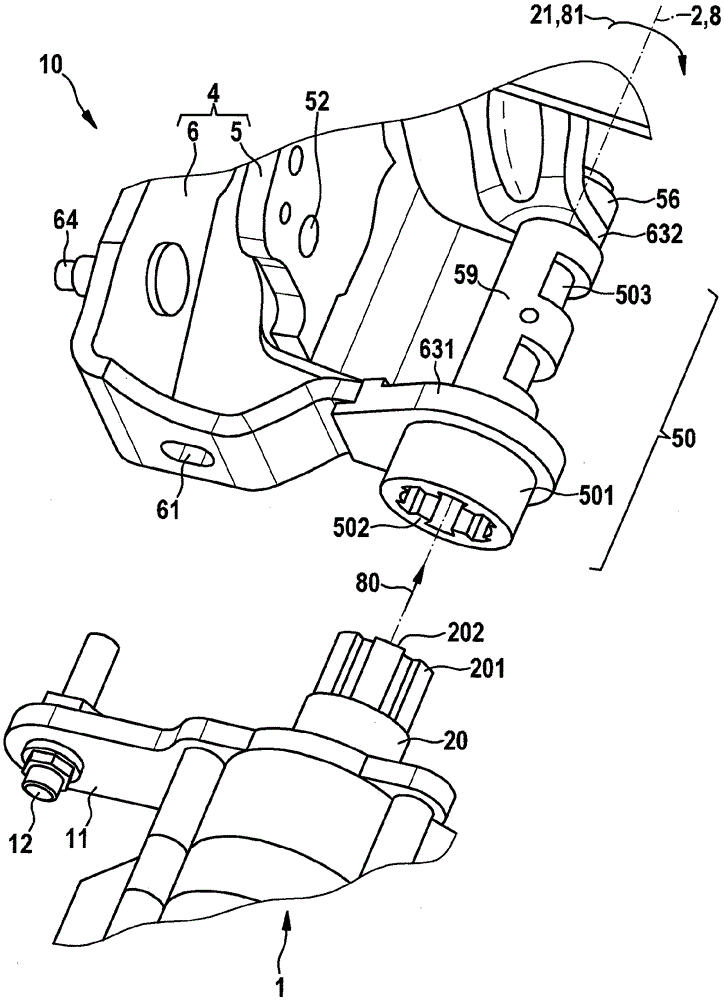

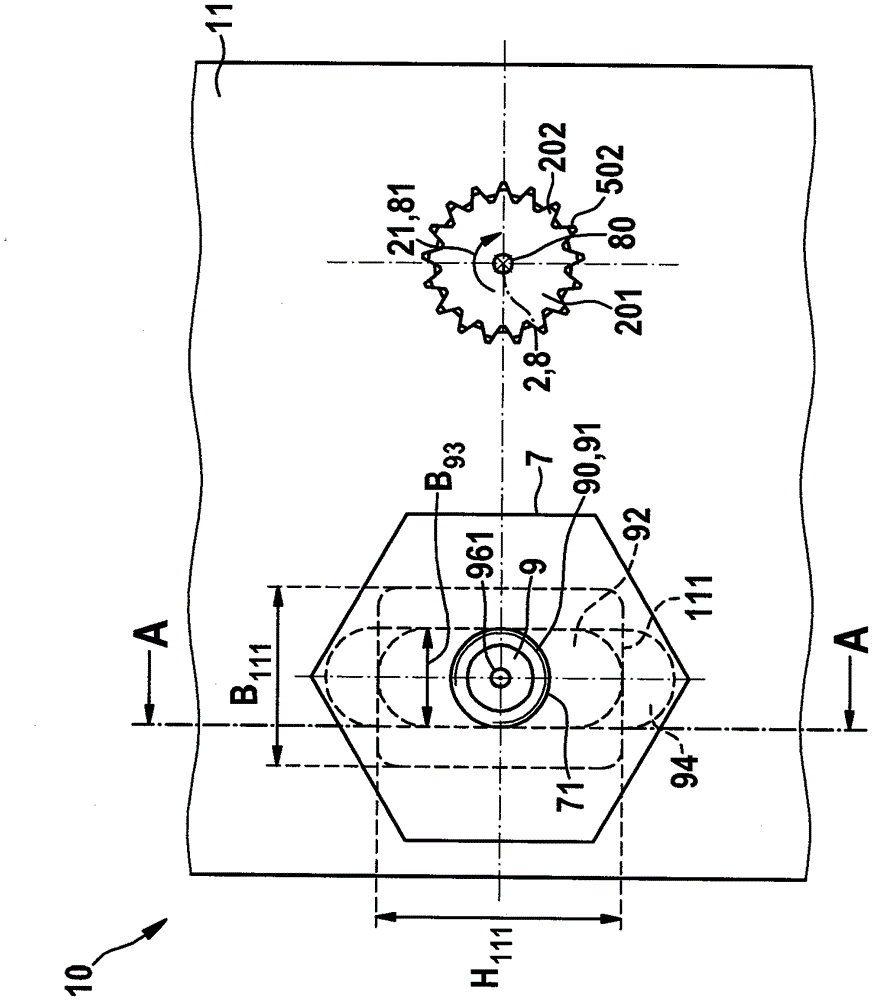

[0032] exist figure 1 The drive mechanism 10 shown in the prior art comprises an adjusting drive 1 with a drive motor and a hinge 4 . The hinge 4 has a first hinge arm 6 and a second hinge arm 5 which is rotatable relative to the first hinge arm 6 about a hinge axis 8 in and against a direction of rotation 81 . The first articulated arm 6 is arranged, for example, in a stationary manner on the vehicle body. The assembly is arranged on said second hinge arm 5 .

[0033] When assembling the drive mechanism 10 , the adjusting drive 1 is pushed onto the hinge 4 in the axial direction 80 and is then fastened to the first hinge arm 6 by means of a support screw 12 , so that The hinge axis 8 and the output axis 2 are arranged aligned with one another, and the adjusting drive 1 and the first hinge arm 6 are arranged in a rotationally fixed manner relative to one another. Depending on the drive mechanism, an assembly in which the hinge is pushed onto the adjusting drive is also pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com