Vacuum overload fuse

A fuse and vacuum technology, which is applied in the field of vacuum overload fuses, can solve the problems of large volume, insensitivity, and complex structure of combined electrical appliances, and achieve the effects of sensitive action, no explosion hazard, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings of the embodiments.

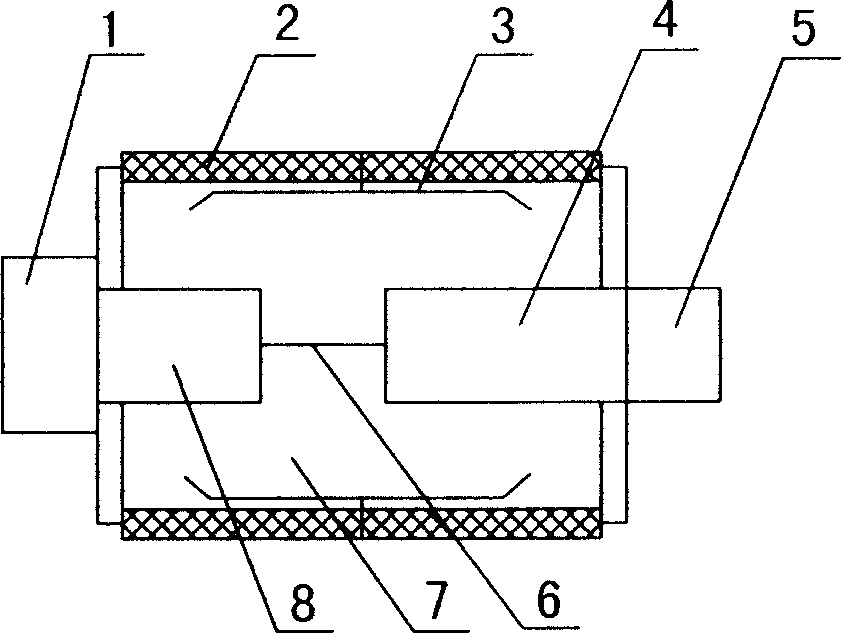

[0016] Such as figure 1 As shown, the vacuum overload fuse of the present invention is a small-sized product, and the melt (copper-nickel alloy wire) 6 is sealed in the vacuum chamber 7 of the insulating porcelain sleeve 2, and the vacuum degree of the vacuum chamber 7 is 5×10 -4 Pa, a metal shield 3 is set between the melt 6 and the insulating porcelain sleeve 2, and the two ends of the melt 6 are connected to the external terminals 1 and 5 through conductive rods (oxygen-free copper rods) 8 and 4 . Terminals 1 and 5 can be processed into any shape suitable for installation as required.

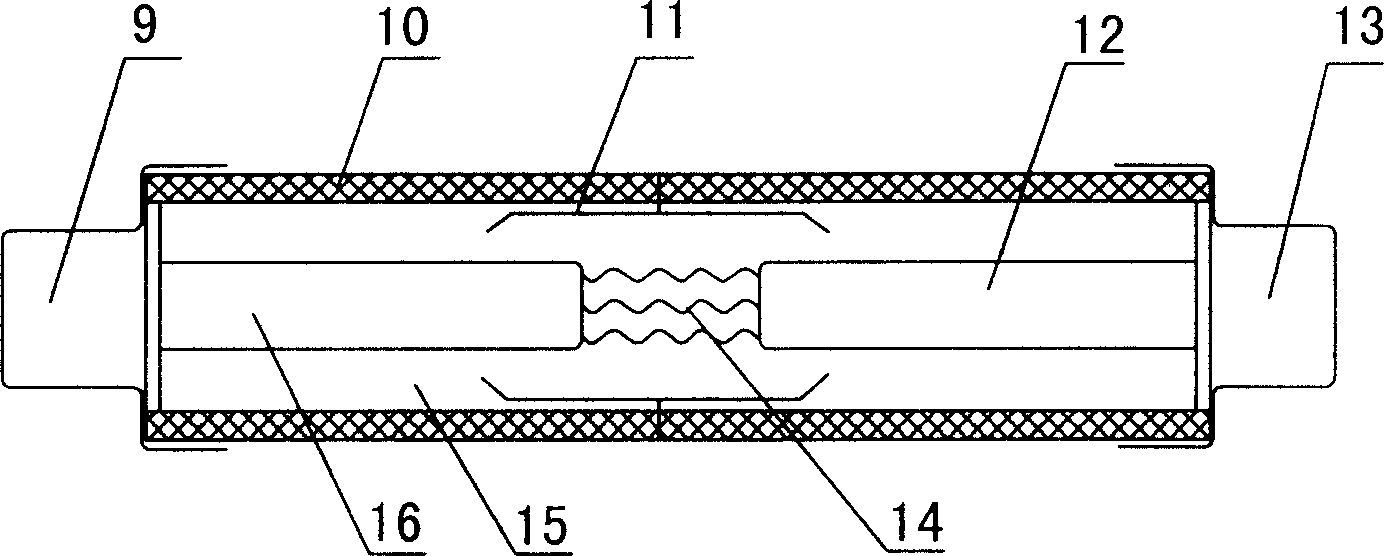

[0017] Such as figure 2 As shown, the vacuum overload fuse of the present invention is a medium-sized and large-sized product with a long length, and the melt (copper-nickel alloy strip) 14 is sealed in the vacuum chamber 15 of the insulating porcelain sleeve 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com