A quarrying method for layered rock mass based on static splitting

A rock mass and static technology, which is applied in open pit mining, earth square drilling, special mining, etc., can solve unfavorable and safe quarrying problems, and achieve the goal of improving quarrying safety, accuracy, and quarrying efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

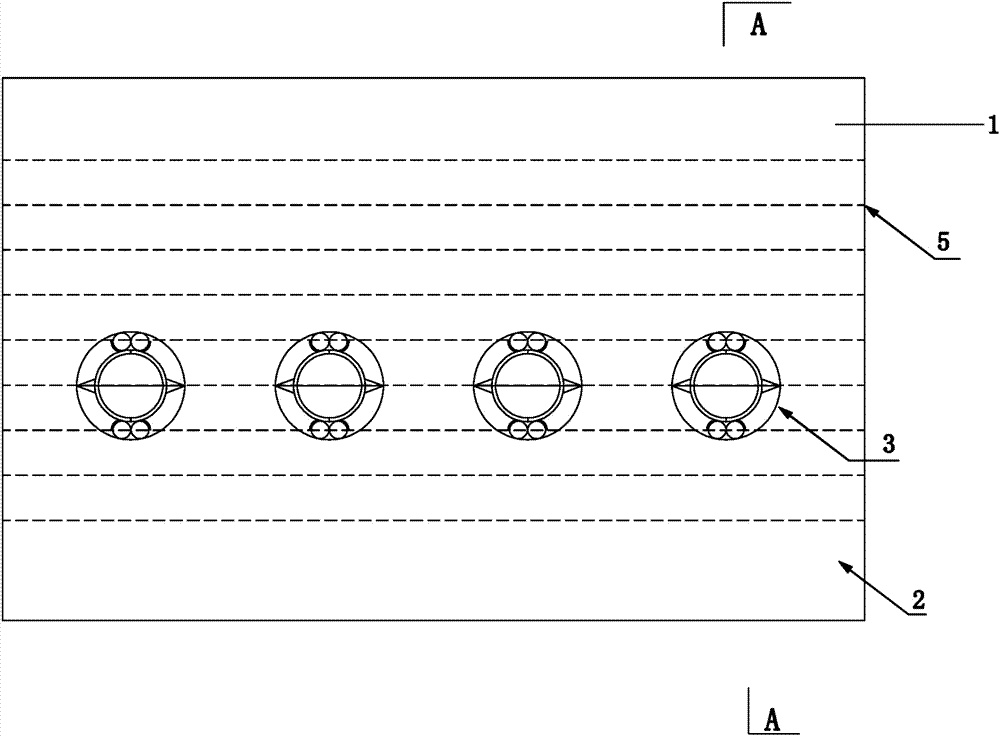

[0035] The mining rock mass is layered sandstone, and the static blasting energy-gathering device 3 and its method of use are a static blasting energy-gathering device and its blasting method disclosed in Chinese Patent Application No. 201510171972.1. The cracking range of the static blasting energy-gathering device 3 is 0.5 meters, and the rock formation is determined to be horizontal through the survey of the rock mass, and the thickness of the rock formation is about 0.2 meters.

[0036] Such as Figure 1-4 Shown, a kind of layered rock mass quarrying method based on static splitting, this method comprises the following steps:

[0037] Step 1: Determine the size of the stones to be collected as L 石 = 1 meter, W 石 = 1 meter, H 石 = 1 meter, available rock mass 1 area L 岩 = 5 meters, W 岩 = 5 meters;

[0038] Step 2: Calculate the number of layers that can be collected on the rock mass 1 that can be mined = the width W of the rock mass that can be mined 岩 / Width of stone...

Embodiment 2

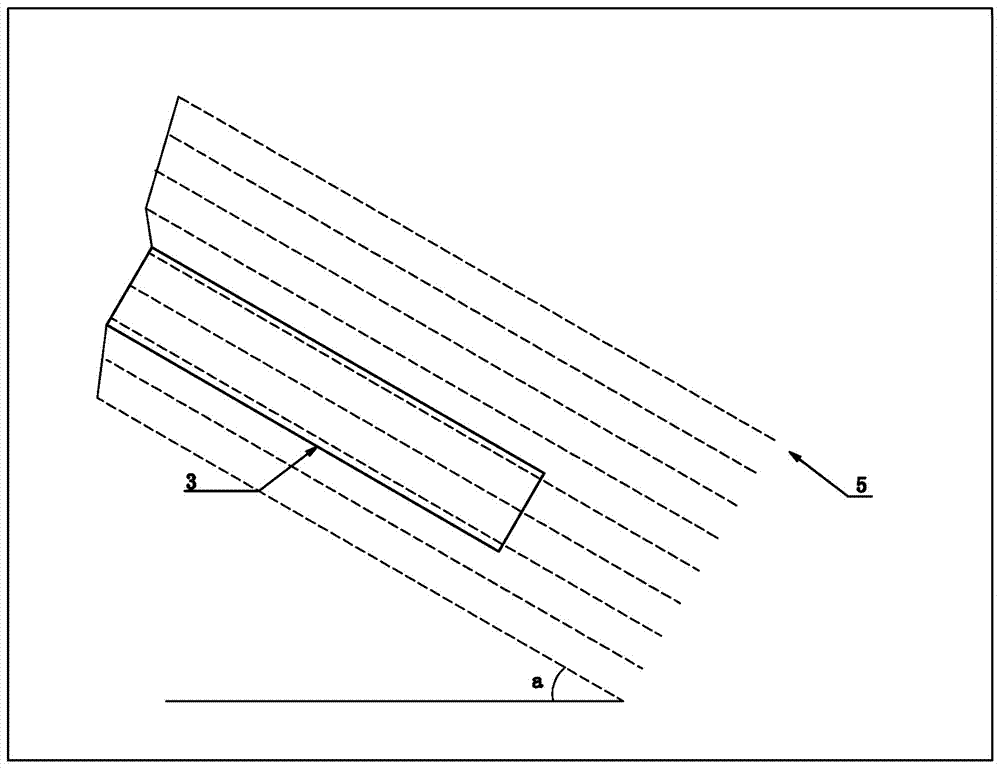

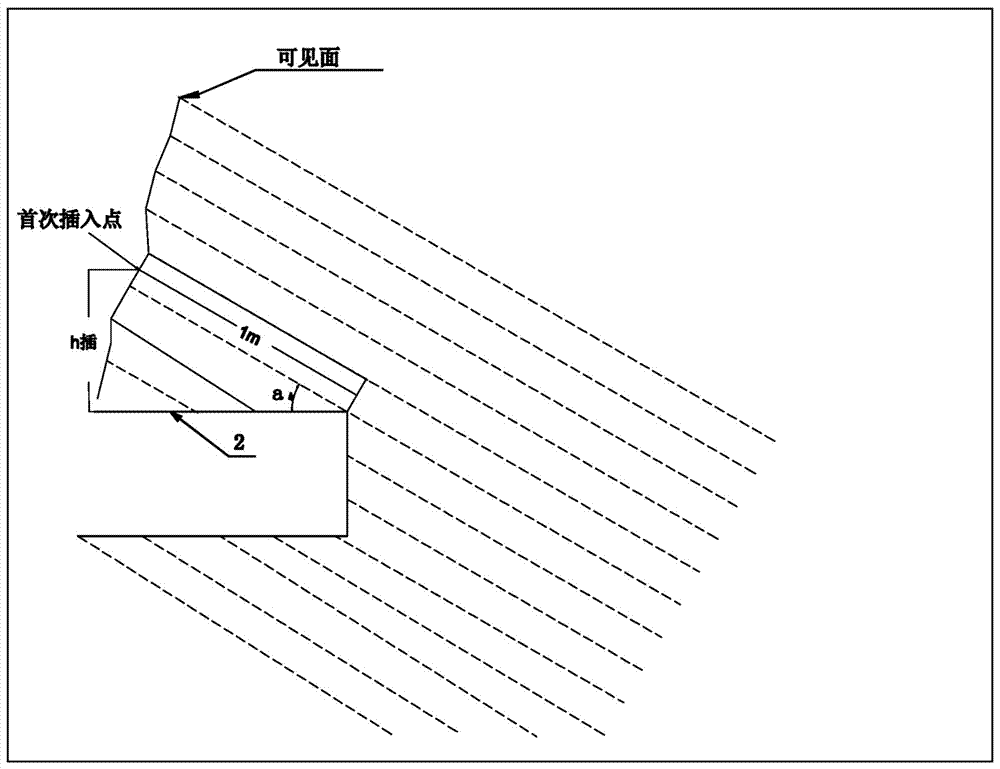

[0056] The rock mass to be mined is mica schist, and the static blasting energy gathering device 3 used and its method of use are a static blasting energy gathering device and its blasting method disclosed in Chinese Patent Application No. 201510171972.1. The cracking range of the blasting energy-gathering device 3 is 0.4 meters. It is determined through the survey of the rock mass that the bedding of the rock mass is about 30 degrees, and the thickness of the rock layer is about 0.1 meter.

[0057] Such as Figure 5-7 Shown, a kind of layered rock mass quarrying method based on static splitting, this method comprises the following steps:

[0058] Step 1: Determine the size of the stones to be collected as L 石 = 2 meters, W 石 = 1 meter, H 石 = 1 meter, available rock mass 1 area L 岩 = 8 meters, W 岩 = 8 meters;

[0059] Step 2: Calculate the number of layers that can be collected on the rock mass 1 that can be mined = the width W of the rock mass that can be mined 岩 / Widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com