Prefabricated Tunnel and Construction Method of Shield Tunnel Joints at Shield Tunnel Intersection and Small Spacing

A small-spacing, tunnel-based technology, applied in tunnels, earthwork drilling, mining equipment, etc., can solve problems such as risk interference and achieve the effects of breaking through space restrictions, shortening safety, and eliminating impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

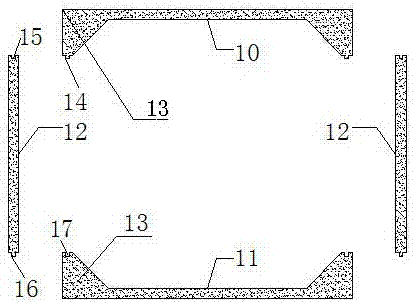

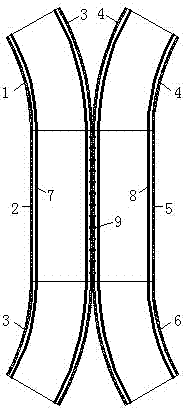

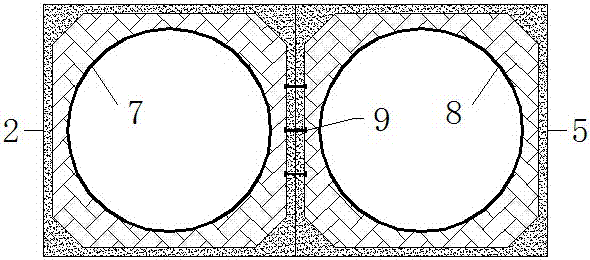

[0040] A prefabricated assembled tunnel with shield intersection and small-pitch shield nodes, which includes two adjacent prefabricated tunnels, namely a left prefabricated tunnel and a right prefabricated tunnel, and each prefabricated tunnel includes a rear curved section, a straight section, and a front curved section respectively. Sections, that is, the rear curve section 1 of the left precast tunnel; the straight section 2 of the left precast tunnel; the front curve section 3 of the left precast tunnel; the rear curve section 4 of the right precast tunnel; the straight section 5 of the right precast tunnel; the front curve section of the right precast tunnel 6. The butt joints of each part are connected with bolts 9; each part of the prefabricated tunnel is integrally cast and formed, and the prefabricated tunnel includes a top plate 10, a bottom plate 11, and a side wall 12 that is connected with the top plate and the bottom plate. A chamfer 13 is provided at the connect...

Embodiment 2

[0044] A construction method for prefabricated assembled tunnels with shield intersections and small-spacing shield nodes, comprising the following steps:

[0045] (1) Manufacture of prefabricated tunnel sections outside the construction site

[0046] The prefabrication steps of the prefabricated tunnel section are as follows: making the formwork of the prefabricated tunnel section, binding the steel cage, reserving bolt holes at the bolt connection parts of the side walls of the prefabricated tunnel section, reserving bolt holes at the butt joints of the longitudinal sections, pouring concrete, curing, and dismantling Template;

[0047] (2) Foundation pit excavation and support

[0048] (1) Excavate the foundation pit to the design depth of the prefabricated tunnel floor, and carry out foundation pit side slope support;

[0049] (2) The bottom of the pit is compacted or grouted within 3-5 meters below the bottom of the pit to reinforce the bottom of the pit;

[0050] (3) I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com