Vertical axis wind driven generator with blades being opened and closed automatically

A technology for automatic opening and closing of wind power generators, which is applied to wind power generators, wind power motor combinations, and wind power generators at right angles to the wind direction, etc. High investment cost and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

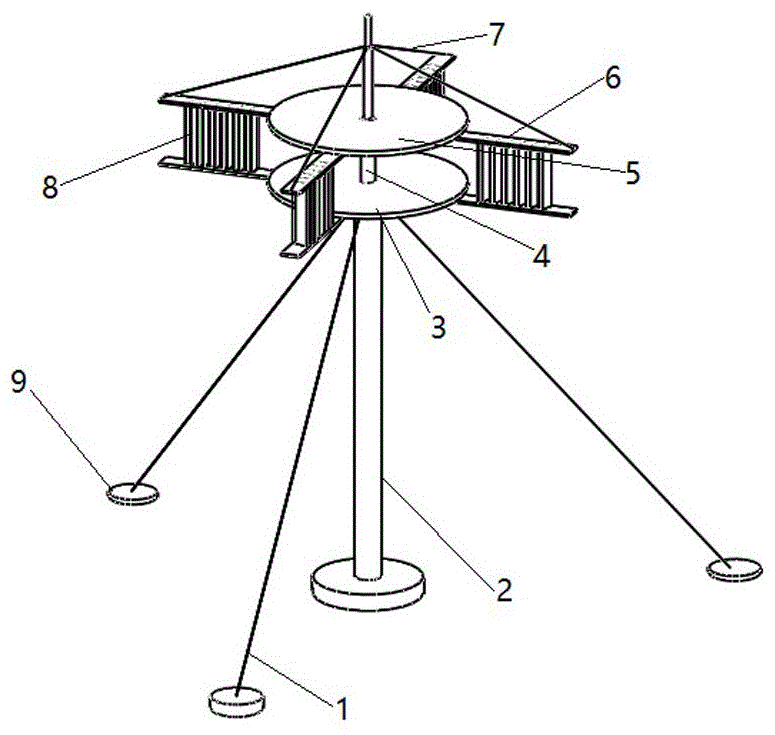

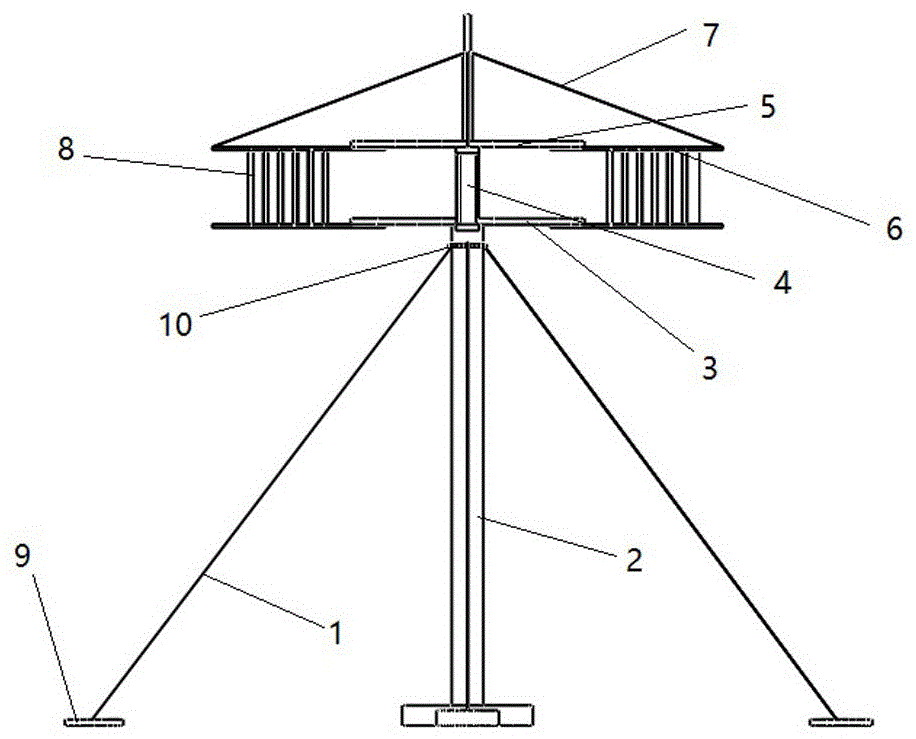

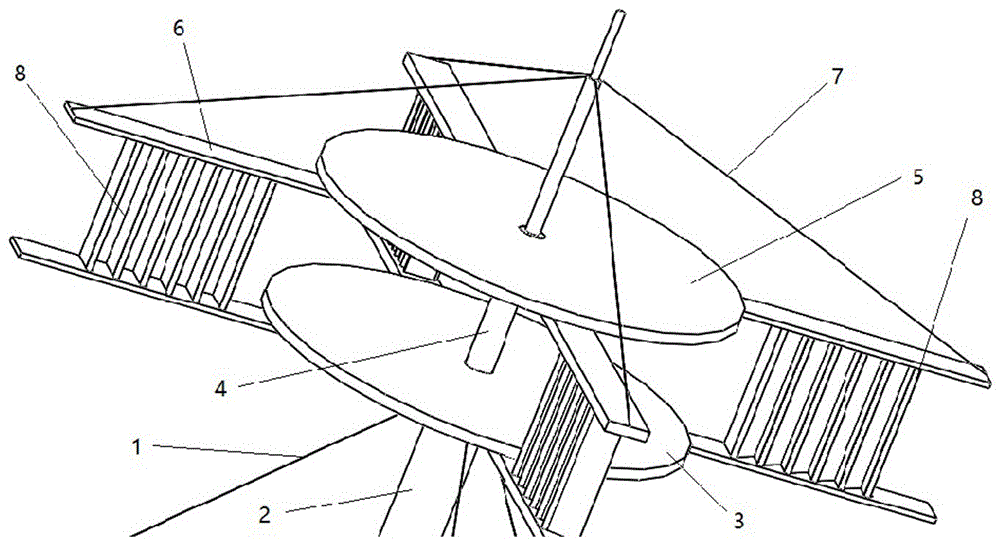

[0079] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a vertical axis wind power generator with automatic blade opening and closing includes a cable reel 9 and a cable 1 connected to the cable reel, and the cable reel is buried in the soil for fixing. Standing on the ground, the pull wire plays the role of stabilizing the pole 2, the pole 2 is connected to the impeller shaft 4 in rotation, the lower disc 3 and the upper disc 5 are fixed on the impeller shaft 4, the lower disc 3 and the upper disc 5 are shaped The same as the quality, the blade bracket 6 is fixed on the upper and lower discs, the blade brackets 6 are symmetrically distributed at equal intervals on the disc, and the wind panel 8 is installed on the blade bracket. The wind panel 8 is composed of two sets of blades, fixed on the blade bracket The blades on 6 are called fixed blades 12. There is a rotating shaft 13 on one side of the fixed blades 12, and the other group of blades rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com