A vertical filter disc filter concentrator

A concentrator and filter disc technology, applied in the field of concentrators, can solve the problems of low underflow concentration and large floor space per unit production capacity, and achieve the effects of large filtration area, compact structure and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

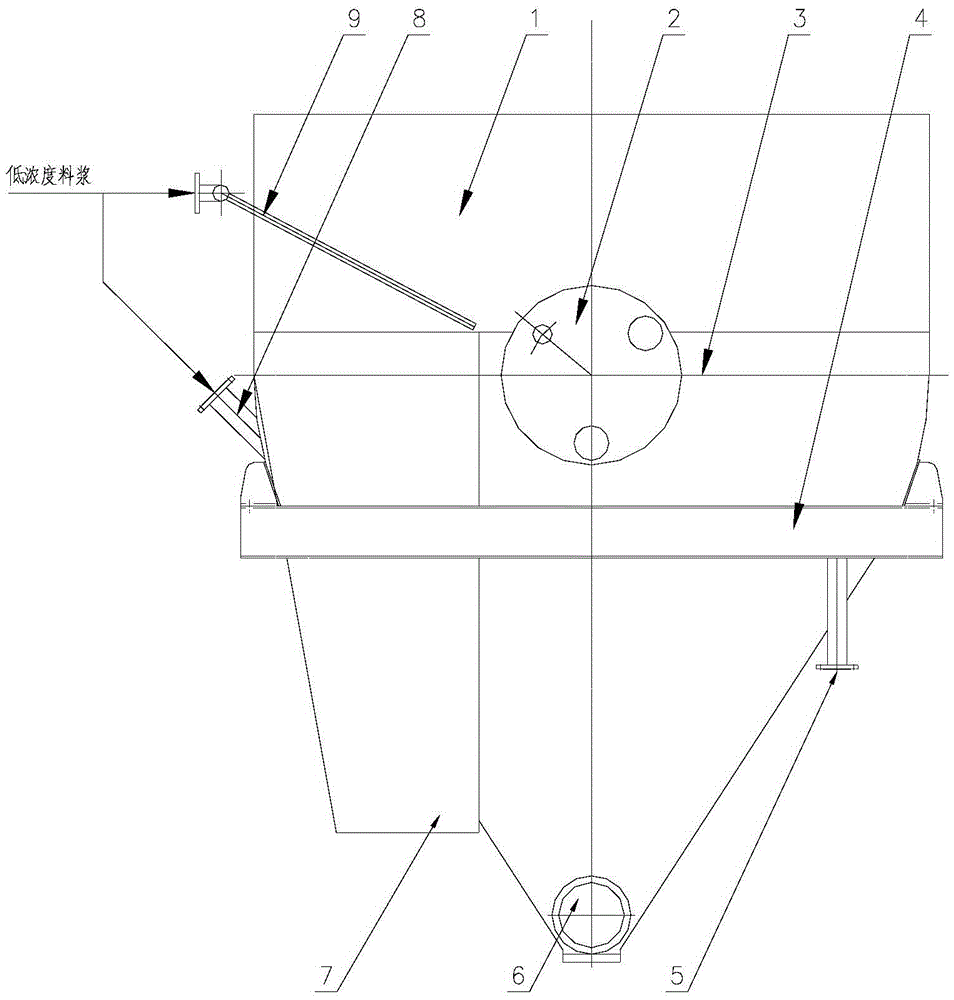

[0032] The present invention provides a vertical filter disc filter concentrator, the concentrator includes a filter disc 1, a material bin 3, a hollow main shaft, a driving device, a distribution valve 2 and a frame 4; the material bin 3 is provided with the filter disc 1, the hollow main shaft passes through the filter disc 1 horizontally, one end of which is provided with the distributing valve 2 and is connected to the driving device, and the silo 3 and the hollow main shaft are supported by the frame 4.

[0033] The filter disc 1 includes a filter disc body and a filter cloth, and the filter cloth covers the filter disc body. There are 1 to 10 filter discs 1 .

[0034] The silo 3 is parallel to the hollow main shaft, and its cross section is an inverted triangle with an opening, and a spiral slagging device 6 is provided at the opening.

[0035] The si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com