Heavy-loaded stepless speed changer

A technology of continuously variable transmission and speed control device, applied in belt/chain/gear, mechanical equipment, transmission device, etc., can solve problems such as difficult to ensure effective friction, unsuitable for heavy-load transmission occasions, torque size limitation, etc. The effect of large effective friction, high transmission reliability and less slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The descriptions of orientations such as top and bottom are quoted in the following, which are based on the orientations shown in the drawings of the specification. In fact, these orientations are relative, and are only for the purpose of clearly and objectively describing the orientation and swing of each component. Orientation does not affect the orientation of the device during actual use.

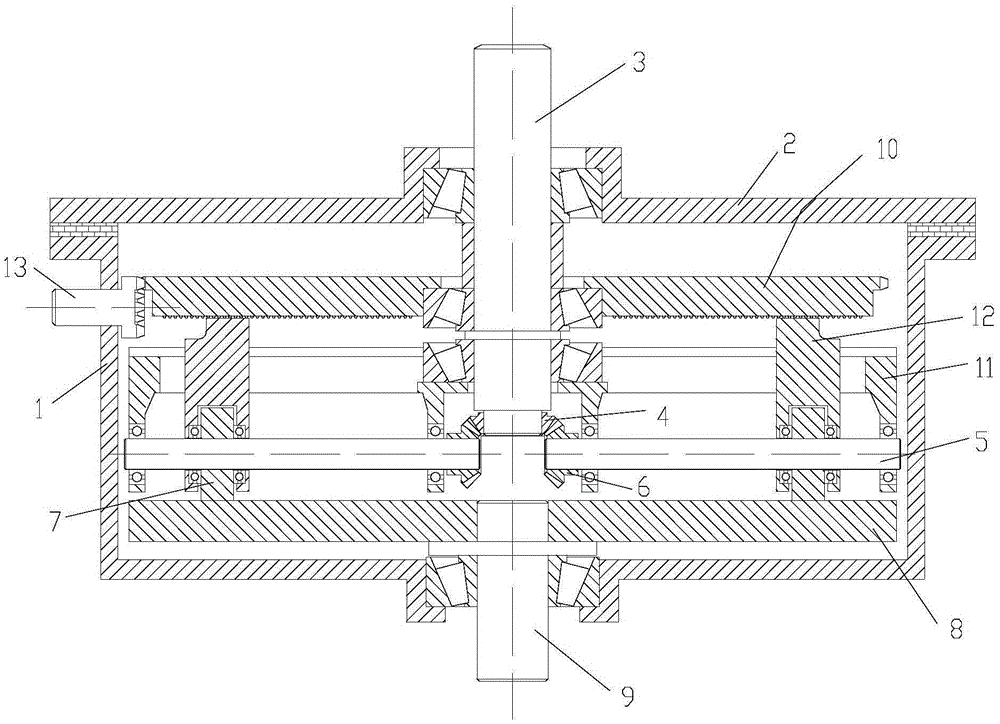

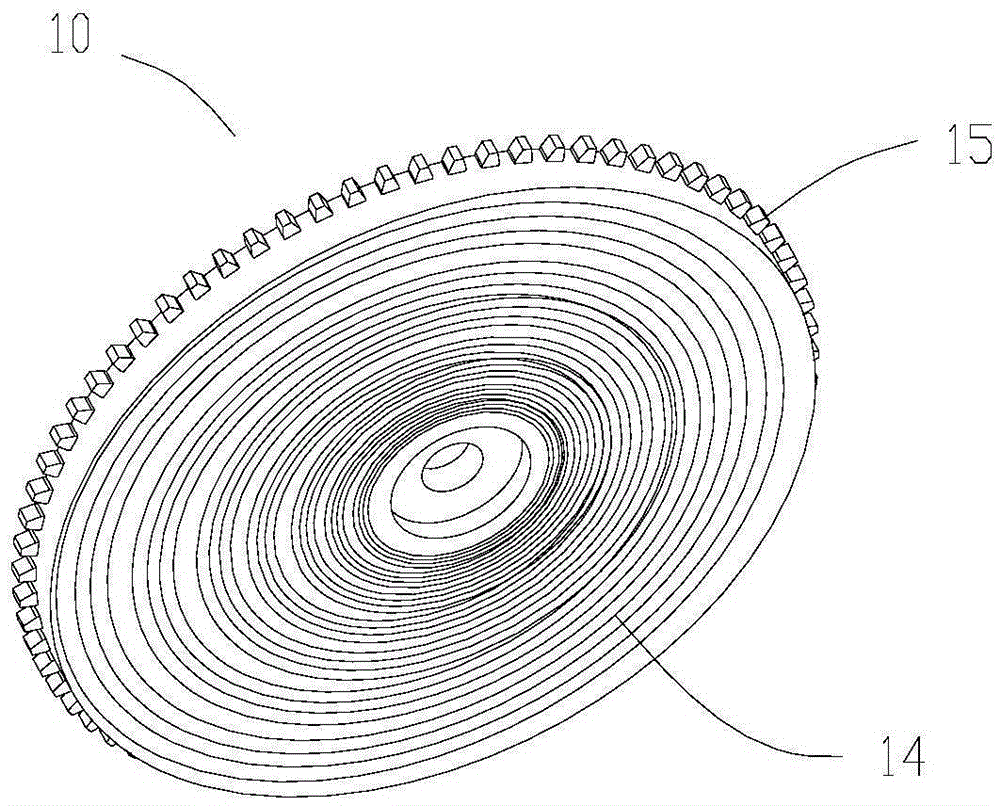

[0033] see figure 1 , the invention discloses a heavy-duty continuously variable transmission, comprising a casing 1, a cover 2, a driving shaft 3, a driving bevel gear 4, a driven shaft 5, a driven bevel gear 6, a speed regulating device, a transmission wheel 7, a turntable 8 and the output shaft 9; the bottom end of the driving shaft 3 is driven and connected with the driving bevel gear 4; the speed regulating device is arranged on the top, the driving shaft 3 passes through the center of the speed regulating device, and the driven shaft 5 is arranged below the speed regulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com