Resistance-free balanced-type ripple compensator

A corrugated compensator and balanced technology, which is applied to expansion compensation devices for pipelines, pipes/pipe joints/pipes, mechanical equipment, etc. The wave number limitation of bellows and other problems can achieve the effect of uniform and stable tension, elimination of swing phenomenon and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

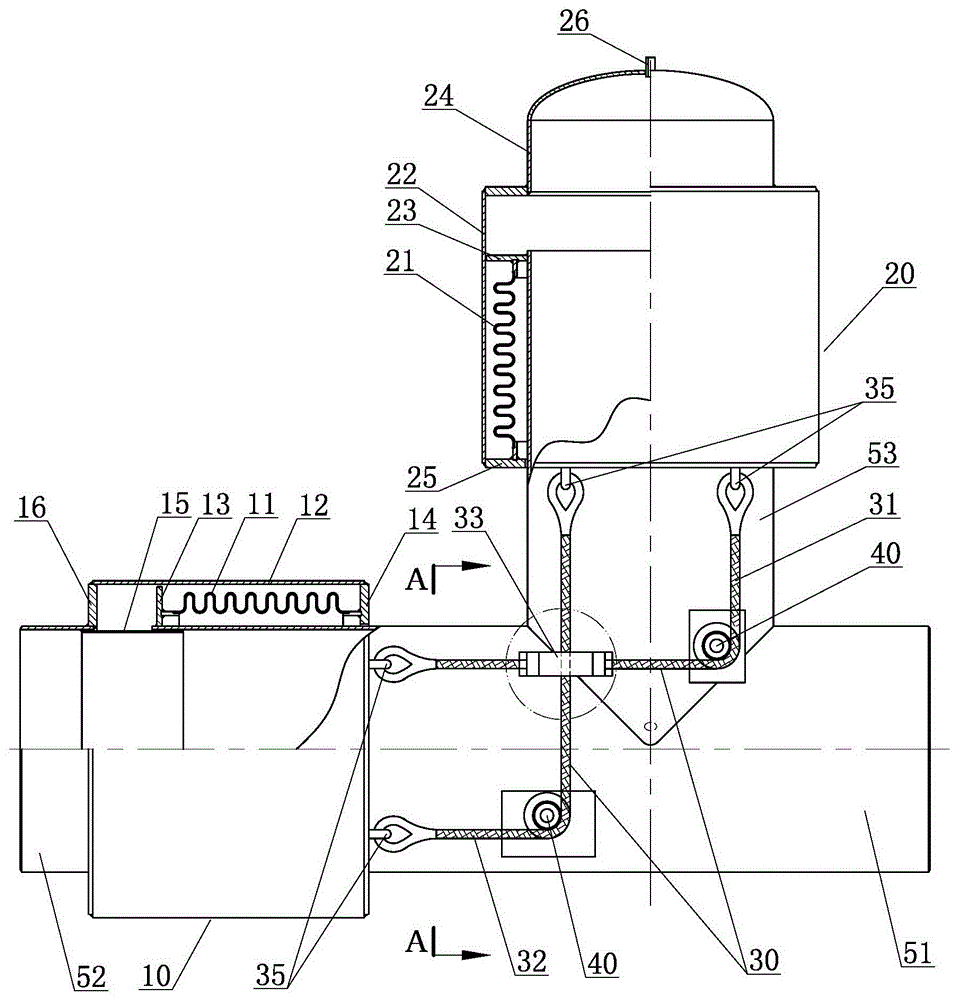

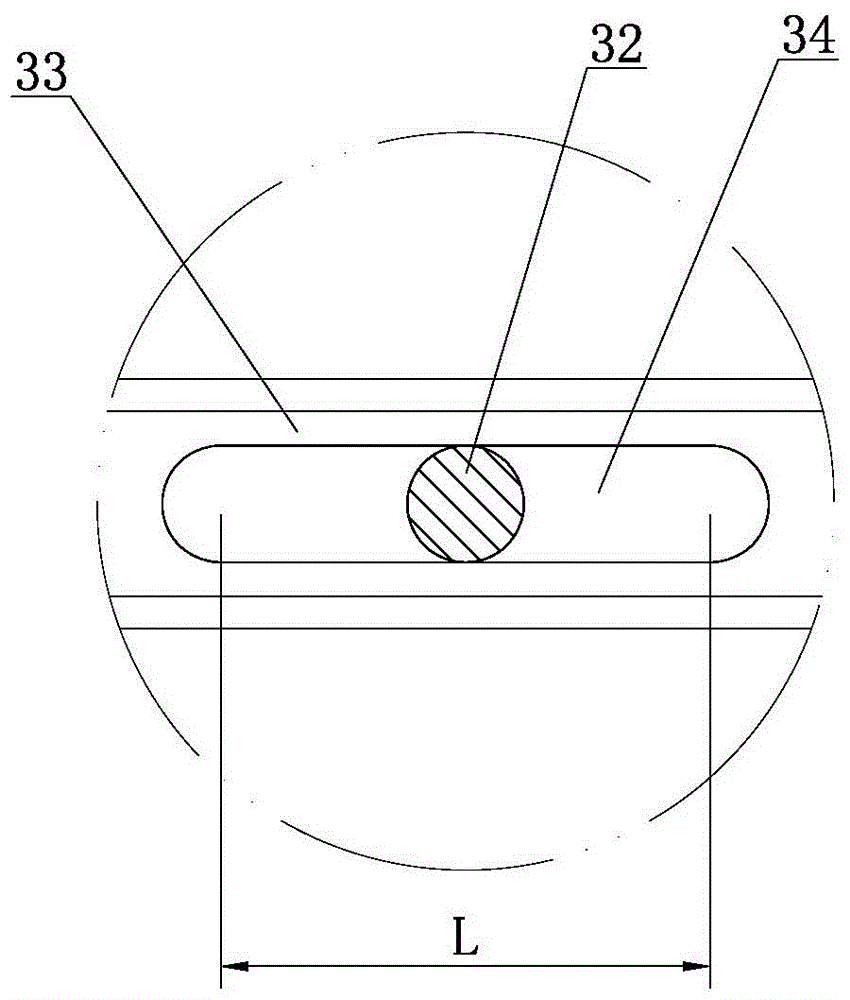

[0030] Such as figure 1 , figure 2 , image 3 , a non-resistance balanced bellows compensator, comprising a working bellows assembly 10 connected to the main pipeline at both ends, and a balanced bellows assembly 20 vertically connected to the main pipeline.

[0031] The structure of the working bellows assembly and the balance bellows assembly is a structure of an external pressure bellows compensator. The conventional external pressure corrugated compensator is provided with an outer cylinder, and the main pipe is divided into two sections in the external pressure corrugated compensator, one is a long pipe and the other is a connecting pipe. The outer cylinder is sheathed outside the long pipe, one end of the outer cylinder is connected to the end of the connecting pipe, and the other end of the outer cylinder is a free end inserted into the long pipe. The bellows is sleeved between the outer cylinder and the long pipe, one end of the bellows is connected with the end of...

Embodiment 2

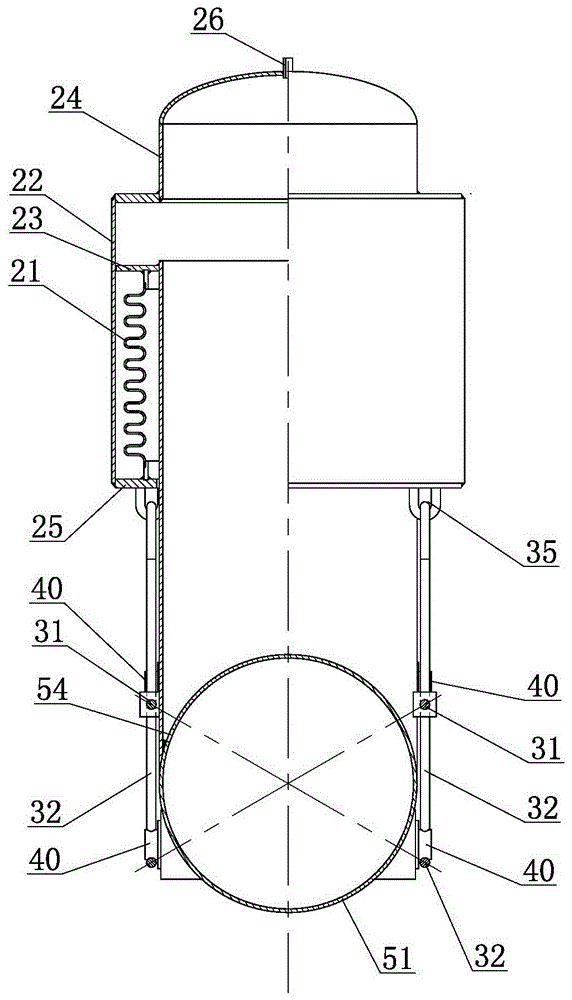

[0043] Such as Figure 4 , a non-resistance balanced bellows compensator, comprising a working bellows assembly 10 connected to the main pipeline at both ends, and a balanced bellows assembly 20 vertically connected to the main pipeline.

[0044] This embodiment is another example of the non-resistance balanced corrugated compensator of the first embodiment. In this embodiment, the balance bellows 53 is arranged under the main pipe (long pipe 51), a communication hole 55 is provided at the low point where the long pipe connects with the balance pipe, and a communication hole 55 is provided at the top (i.e., the lowermost end) of the head 24. Excretion port 27 is arranged. Such an arrangement is beneficial to discharge the medium in the main pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com