A ceramic foam burner for burning waste oil

A foamed ceramic and waste oil technology, which is applied in the burner, combustion method, combustion type and other directions, can solve the problems such as the adhesion of waste oil, insufficient combustion of waste oil, and inability to apply waste oil, so as to avoid poor work, The effect of solving insufficient bonding and burning and reducing maintenance workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

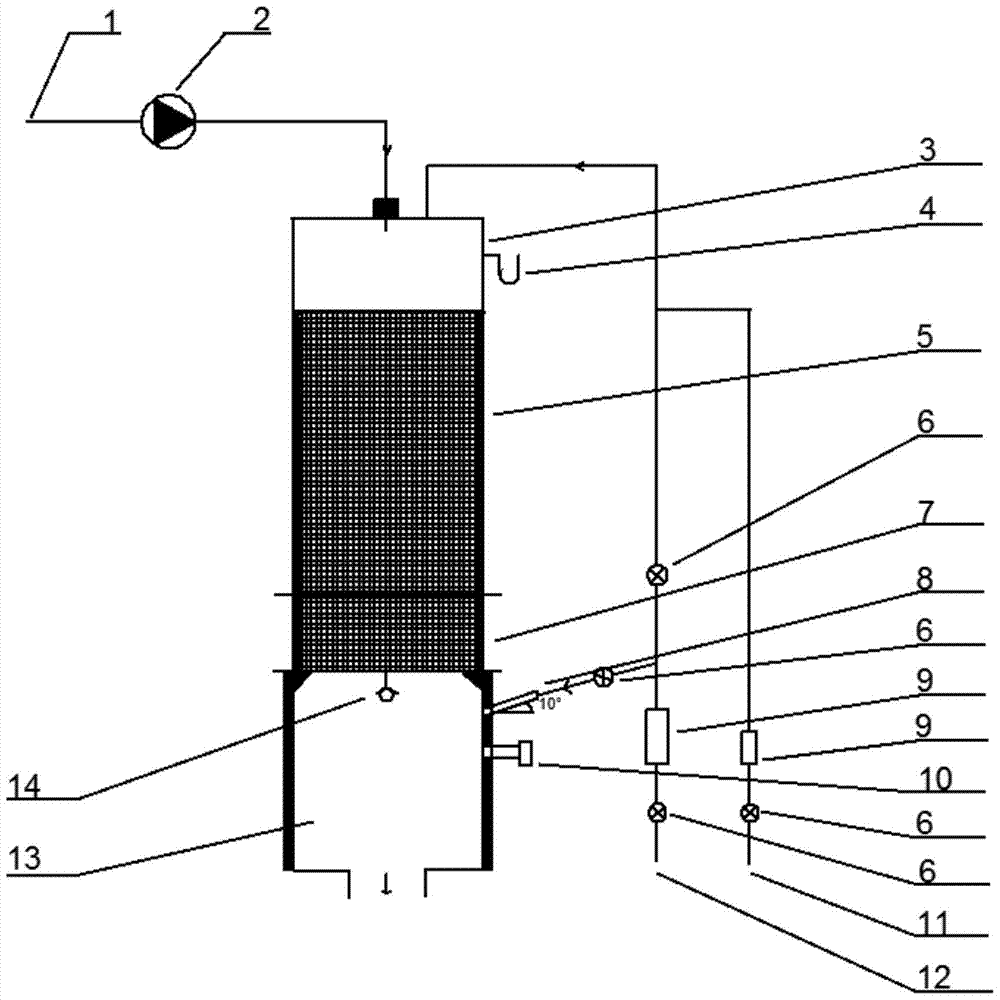

[0015] A new type of ceramic foam burner for burning waste oil, including three parts: a supply device, a ceramic evaporation section and a combustion section.

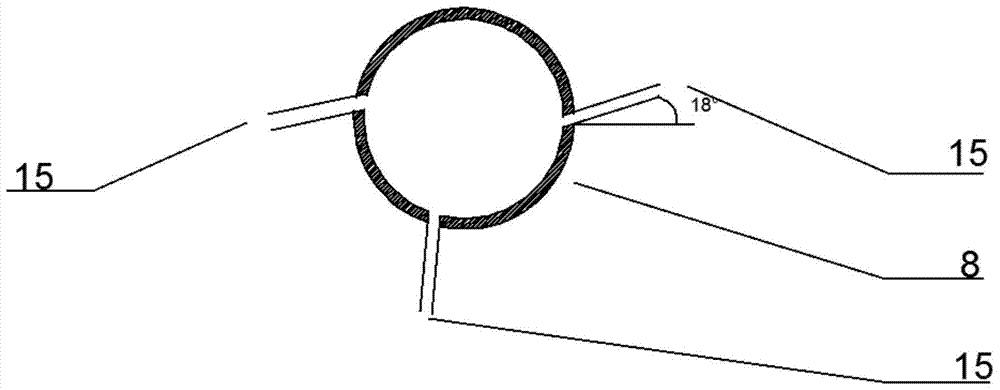

[0016] The waste oil enters the oil injection chamber 3 from the waste oil inlet 1 through the low-pressure oil supply pump 2, the U-shaped pressure gauge 4 is connected with the oil injection chamber 3, the preheating section 5 of the evaporation section is connected with the oil injection chamber 3, and the replaceable main evaporation section 7 is connected with the preheating chamber 3. The hot section 5 is connected, the one-way valve 14 is connected with the main evaporation section 7, the combustion chamber 13 is connected under the main evaporation section 7, the upper part of the combustion chamber 13 is connected with the swirl air intake device 8, and the middle part of the combustion chamber 13 is connected with the igniter 10; the compressed air inlet 12 connects the valve part 6 and the flow meter 9 to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com