Domestic rubbish disposal device convenient for slag discharging

A technology of domestic garbage and treatment equipment, applied in the direction of indirect carbon dioxide emission reduction, combustion method, combustion type, etc., can solve problems such as land erosion, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

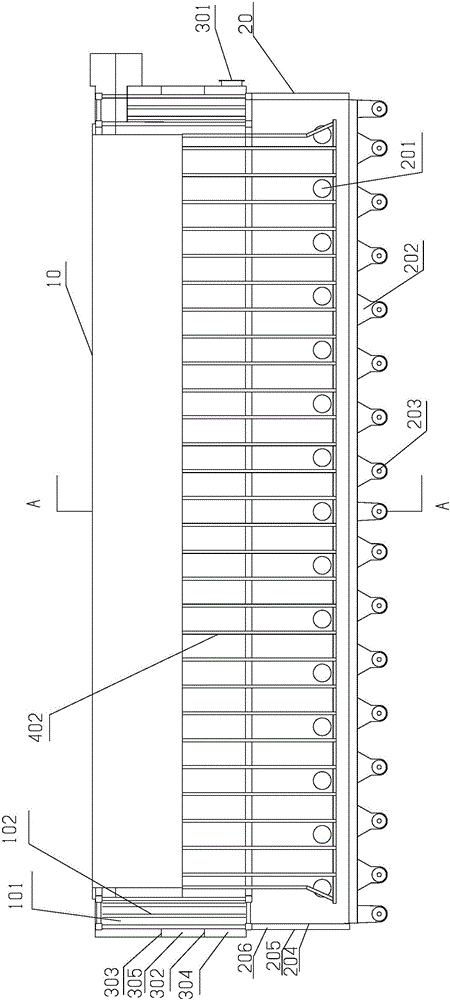

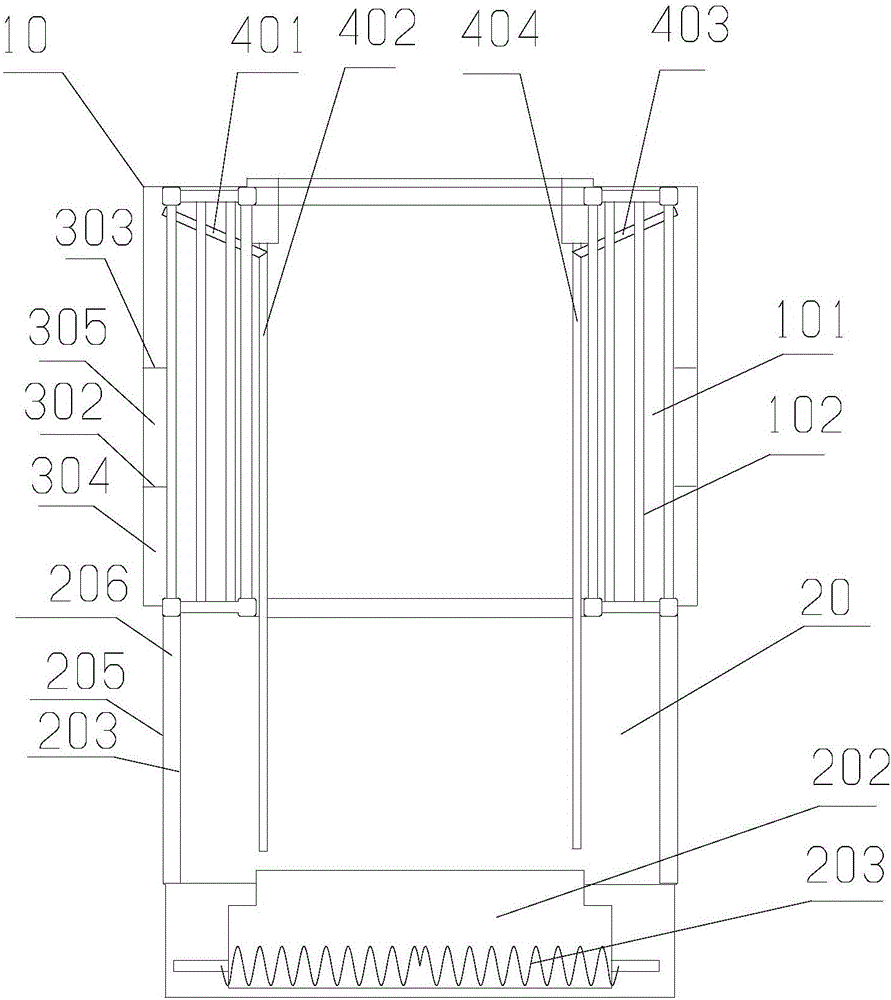

[0015] refer to figure 1 , figure 2 , the present invention proposes a domestic waste treatment device that is convenient for slag removal, including a combustion furnace body, an intake air preheating mechanism and an air guiding mechanism, and the combustion furnace body includes an upper furnace body 10 and a lower furnace body 20 connected to each other, wherein:

[0016] The upper body of furnace 10 is provided with a first annular cooling chamber 101, the furnace wall of the upper body of furnace 10 is provided with a third gas outlet communicating with the first annular cooling chamber 101, and the first annular cooling chamber 101 is provided with the lower furnace body 20 connected to the second air inlet, the first annular cooling cavity 101 is vertically arranged with multi-layer cooling pipes 102, and cooling water is provided in the cooling pipes 102.

[0017] The lower furnace body 20 includes an inner casing 204 and an outer casing 205, a second annular coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com