A method for detecting corrosion degree of pipe fittings

A pipe fitting and pipe measuring technology, applied in the field of ultrasonic thickness measurement, can solve the problems of inaccurate thickness, inaccurate ultrasonic sound velocity, no corrosion degree of pipe fittings, etc., and achieve the effect of accurate corrosion degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This example is used to illustrate the method for detecting the degree of corrosion of 20# carbon steel pipe fittings.

[0030] (1) Measure the thickness D of 20# carbon steel pipe fittings at 25°C with a vernier caliper to be 13.15mm;

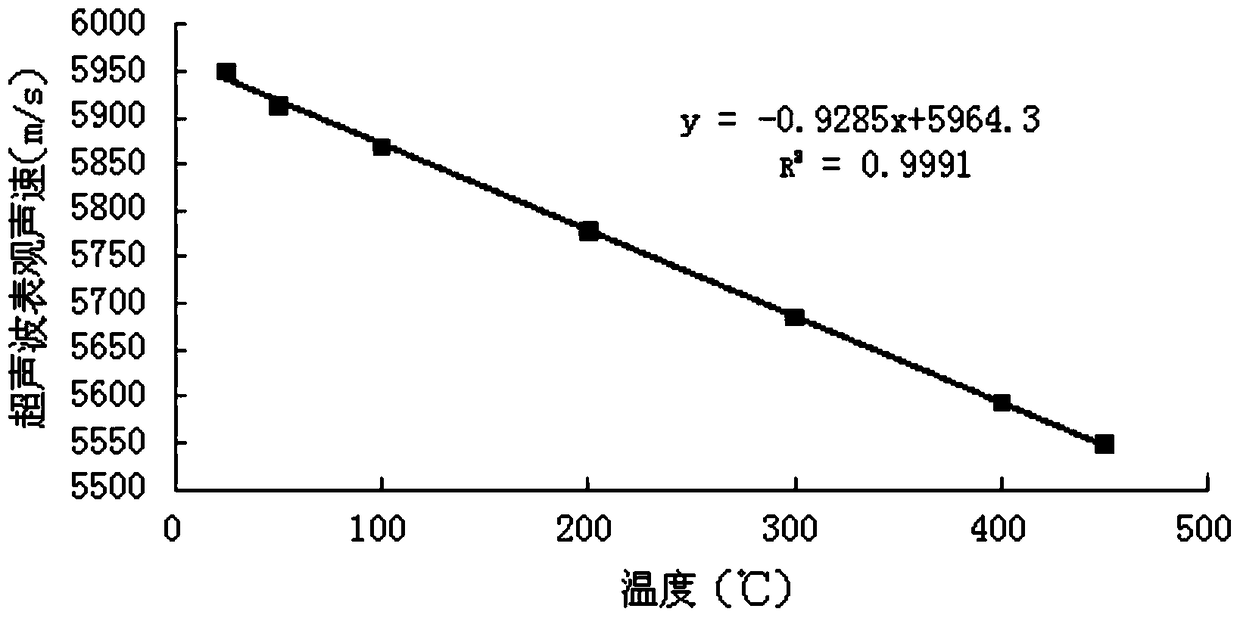

[0031] (2) Take the 20# carbon steel pipe fitting in step (1) as the standard sample, and take the thickness D (i.e. 13.15mm) measured in step (1) as the benchmark, at 25°C, set the ultrasonic sound velocity v to 5000m / s, Using an ultrasonic thickness gauge to measure the thickness of 20# carbon steel pipe fittings at 25°C, the obtained thickness value d is 11.05mm. The time t' used for propagation in 20# carbon steel pipe fittings is 0.00221s, the ratio of the thickness D (ie 13.15mm) measured in step (1) to the time t' (ie 0.00221s) is the ultrasonic wave at 25°C in 20# carbon The superficial sound velocity of ultrasonic waves in steel pipe fittings is 5950m / s.

[0032] (3) Heat 20# carbon steel pipe fittings to 50°C, 100°C, 200°C, ...

Embodiment 2

[0035] This example is used to illustrate the method for detecting the corrosion degree of 321 stainless steel pipe fittings.

[0036] (1) Measure the thickness D of 321 stainless steel pipe fittings at 25°C with a vernier caliper to be 24.32mm;

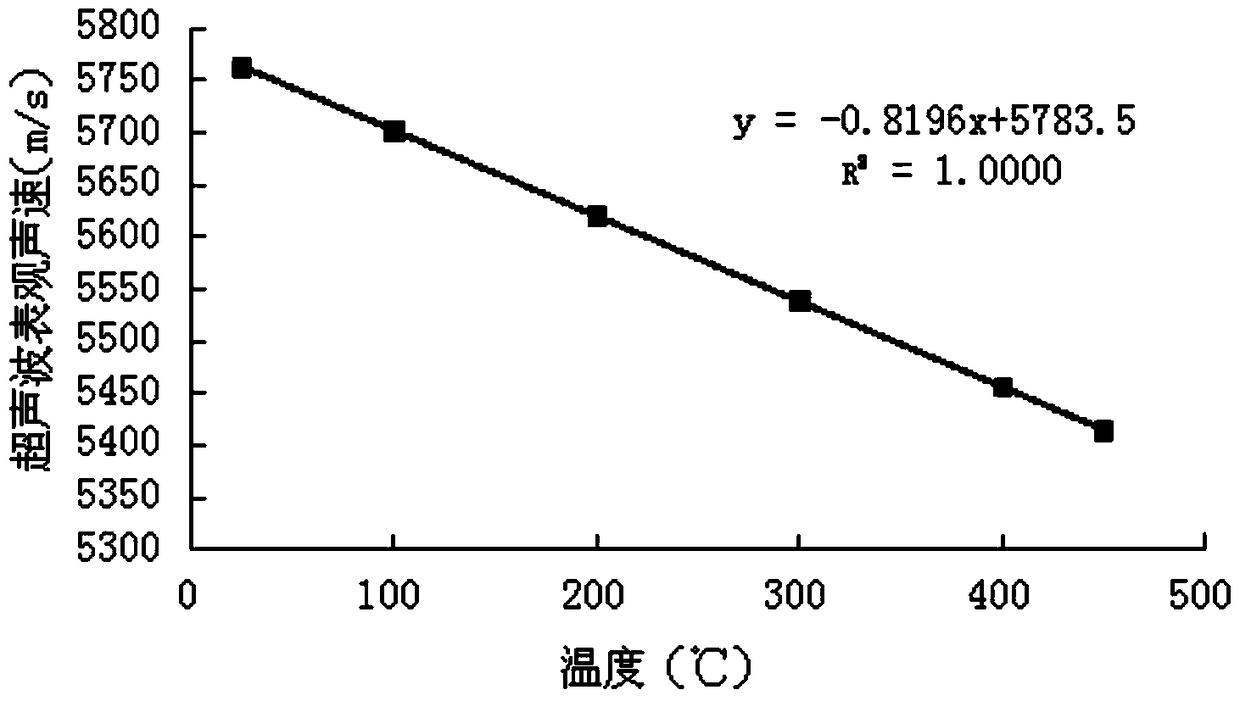

[0037] (2) Take the 321 stainless steel pipe fitting in step (1) as the standard sample, and take the thickness D (ie 24.32mm) measured in step (1) as the reference, set the ultrasonic sound velocity v to 5000m / s at 25°C, and use ultrasonic The thickness gauge measures the thickness of 321 stainless steel pipe fittings at 25°C, and the obtained thickness value d is 21.10mm. The time t' used for propagation is 0.00422s, and the ratio of the thickness D (ie 24.32mm) measured in step (1) to the time t' (ie 0.00422s) is the superficial sound velocity of ultrasonic waves in 321 stainless steel pipe fittings at 25°C , is 5763m / s.

[0038] (3) Heat the 321 stainless steel pipe fittings to 100°C, 200°C, 300°C, 400°C and 450°C respectively,...

Embodiment 3

[0041] This example is used to illustrate the method for detecting the corrosion degree of 304 stainless steel pipe fittings.

[0042] (1) Measure the thickness D of 304 stainless steel pipe fittings at 25°C with a vernier caliper to be 9.55mm;

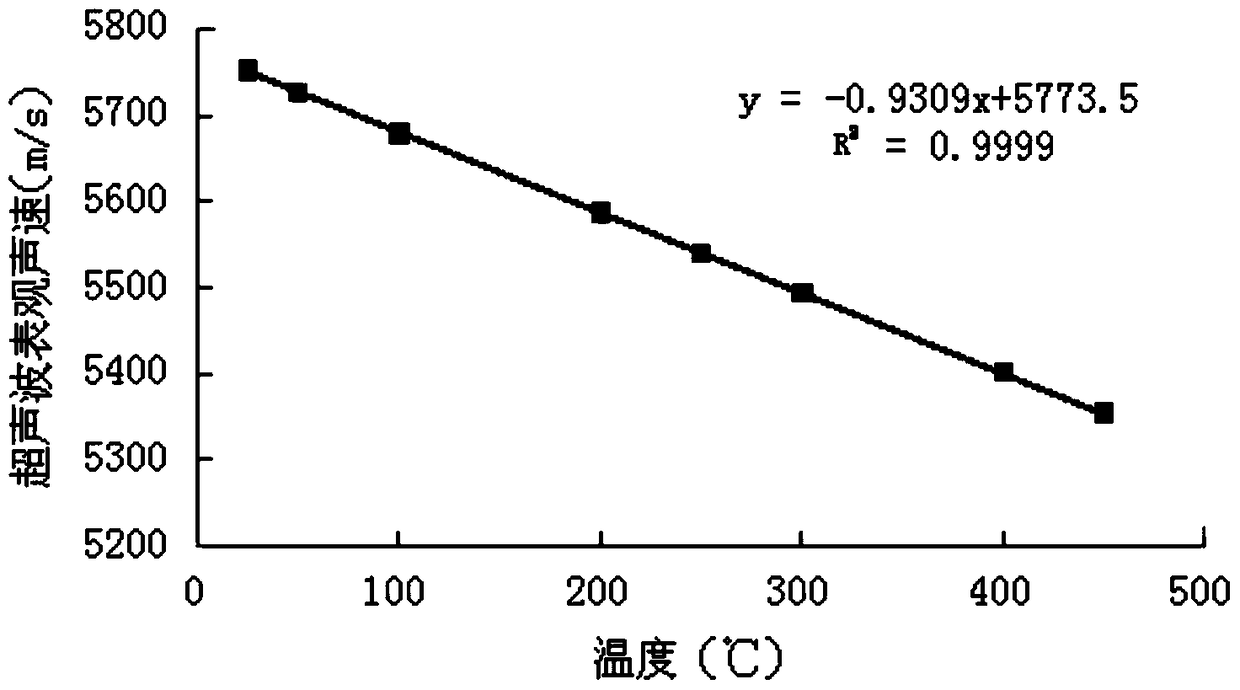

[0043] (2) Take the 304 stainless steel pipe fitting in step (1) as the standard sample, and take the thickness D (9.55mm) measured in step (1) as the reference, set the ultrasonic sound velocity v to 5000m / s at 25°C, and use ultrasonic The thickness gauge measures the thickness of 304 stainless steel pipe fittings at 25°C, and the obtained thickness value d is 8.30mm. The time t' used for propagation is 0.00166s, and the ratio of the thickness D (ie 9.55mm) measured in step (1) to the time t' (ie 0.00166s) is the superficial sound velocity of ultrasonic waves in 304 stainless steel pipe fittings at 25°C , is 5753m / s.

[0044] (3) Heat the 304 stainless steel pipe fittings to 50°C, 100°C, 200°C, 250°C, 300°C, 400°C and 450°C respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com