Prediction method of beer flavor refreshing time

A prediction method and technology for beer flavor, applied in measurement devices, special data processing applications, instruments, etc., can solve problems such as time-consuming, cumbersome operation, and inconsistency in evaluation results, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

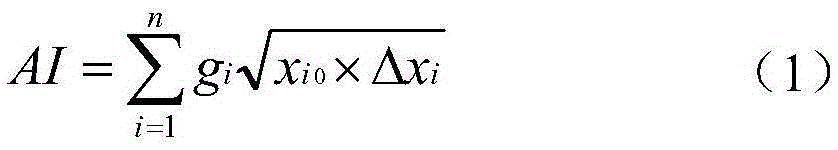

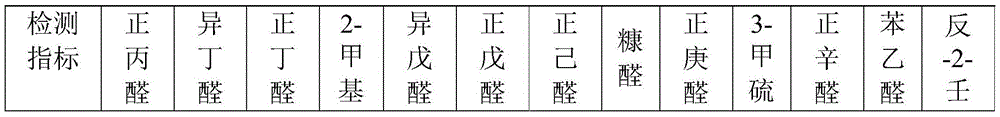

[0034] Example 1. Establishing a Prediction Model for the Freshness Period of Beer Flavor Based on Aldehyde Substances

[0035] Follow the steps below to establish a beer flavor preservation period prediction model:

[0036] (A) Establishment of prediction model

[0037] A-1) Collect 129 10-degree beer samples with a time span of 12 months, evaluate and score the aging taste of beer, and detect the aging aldehyde content at the same time, and calculate the contribution rate of each aldehyde to aging. The operation is as follows:

[0038] 1) Tasting and scoring of beer sample aging: The wine tasting staff shall be persons who have undergone systematic wine tasting training and obtained the national wine tasting judge certificate, and the number shall not be less than 10. The scoring criteria are as follows: only the aging taste of beer is scored, and the scoring is carried out in the form of a 9-point system. The higher the score, the more serious the aging of the beer. 5 (5....

Embodiment 2

[0119] Embodiment 2, using the model in embodiment 1 to predict the flavor preservation period of the beer sample to be tested

[0120] The 10°P pure draft beer produced by the thirteenth packaging workshop of Beijing Yanjing Beer Co., Ltd. on October 26, 2010 was selected, and the just-filled beer samples were randomly selected on the production line, and the aldehydes were determined according to Example 1. Method, the contents of aging aldehydes in the initial and fortified samples of the beer samples were determined respectively, and the results are shown in Table 4.

[0121] Table 4. Detection results of aged aldehydes in 10°P pure draft beer produced in the 13th packaging workshop on 2010.10.26

[0122]

[0123] The calculated AI value of the sample is 0.203, and the F value is 105.8 days. The samples were stored at room temperature and subjected to aging tastings every 10 days and were scored as follows:

[0124] Table 5, 2010.10.26 13th Packing Workshop Production...

Embodiment 3

[0127] Embodiment 3, use the model in embodiment 1 to predict the flavor preservation period of the beer sample to be tested

[0128] Select the 10 ° P refreshing beer produced by the fifteenth packaging workshop of Beijing Yanjing Beer Co., Ltd. on October 8, 2010, randomly extract just-filled beer samples on the production line, and according to the assay method of aldehydes in Example 1, The content of aged aldehydes in the initial and fortified samples of the beer samples were measured respectively, and the results are shown in Table 6.

[0129] Table 6. 2010.10.8 15th Packing Workshop Produced 10°P Refreshing Beer Aged Aldehyde Test Results

[0130]

[0131] The calculated AI value of the sample is 0.308, and the F value is 39.3 days. The samples were stored at room temperature and subjected to aging tastings every 10 days and were scored as follows:

[0132] Table 7, 2010.10.8 15th Packing Workshop Production 10°P Refreshing Beer Aging Score Results

[0133]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com