Diesel locomotive asynchronous motor fuzzy speed device control method

An asynchronous motor, fuzzy control technology, applied in motor generator control, electronic commutation motor control, control system and other directions, can solve the problems of limited motor linear model, speed error, poor robustness and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

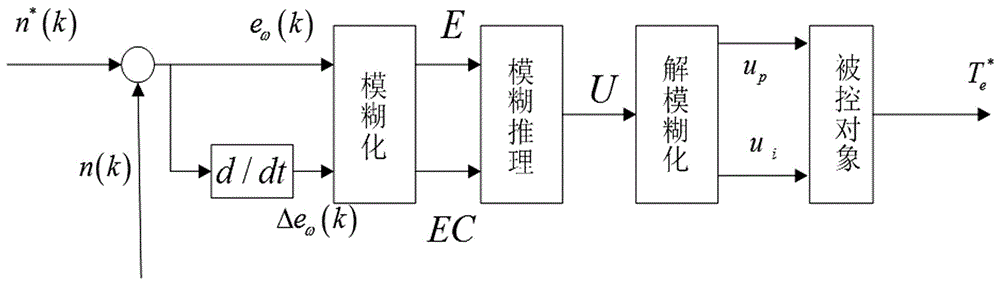

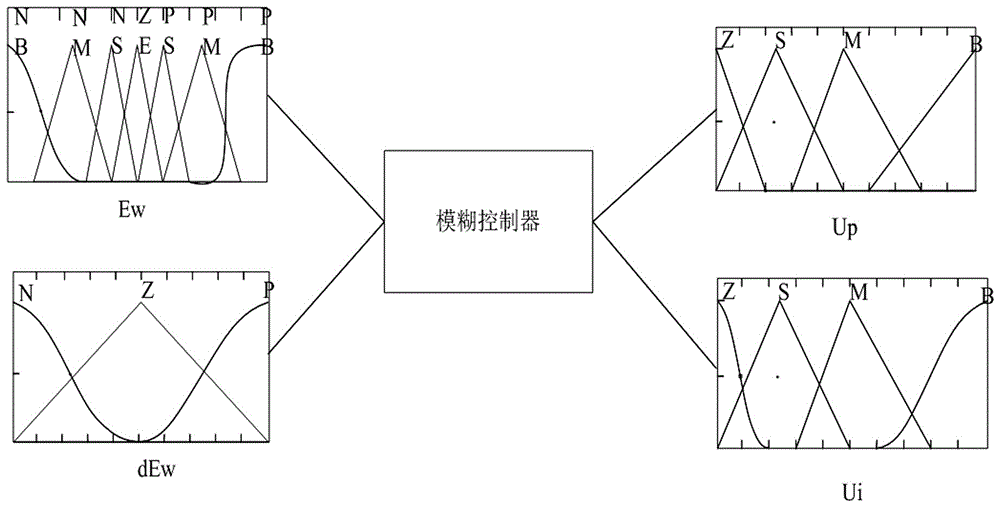

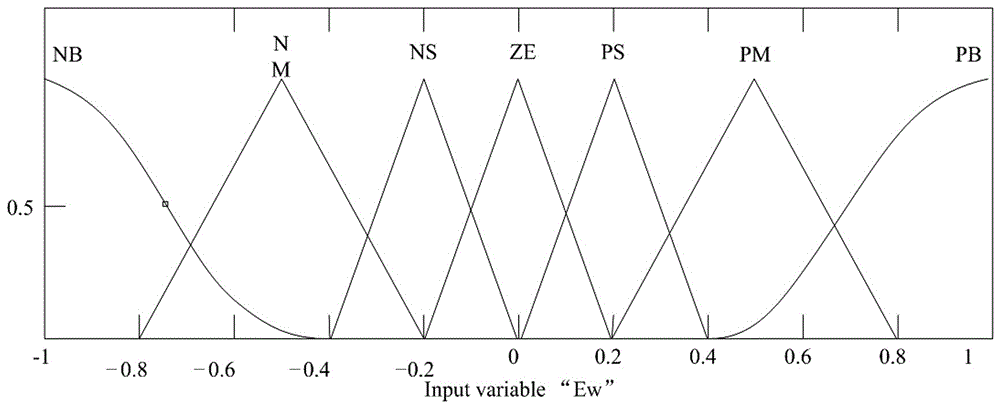

[0026] The invention relates to a fuzzy speed controller control method for an asynchronous motor of an internal combustion locomotive, which is used to improve the torque error and speed error caused by the inability of the asynchronous motor to quickly follow a given speed. Depend on figure 1 It can be seen that the fuzzy speed controller takes the error of the speed as the input and the fuzzy information converted from the precise quantity as the input. Through DSP, the fuzzy reasoning is carried out according to the control parameters and control rules obtained from the manual control experience, and then the fuzzification is defuzzified. Convert fuzzy volumes to precise volumes. like figure 2As shown, the fuzzy controller with 2 inputs and 2 outputs, the input is the speed change Ew, the differential of the speed change dEw, the output is the proportional parameter Up, and the integral parameter Ui; the specific method is as follows:

[0027] (1) Establish fuzzy subset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com