Cold rolling band steel plate shape intelligent optimization control method

A technology of intelligent optimization and control method, applied in the field of cold-rolled strip steel, can solve the problems of low quality control of cold-rolled strip product shape, incomplete consideration of factors affecting the shape of transmission time lag, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

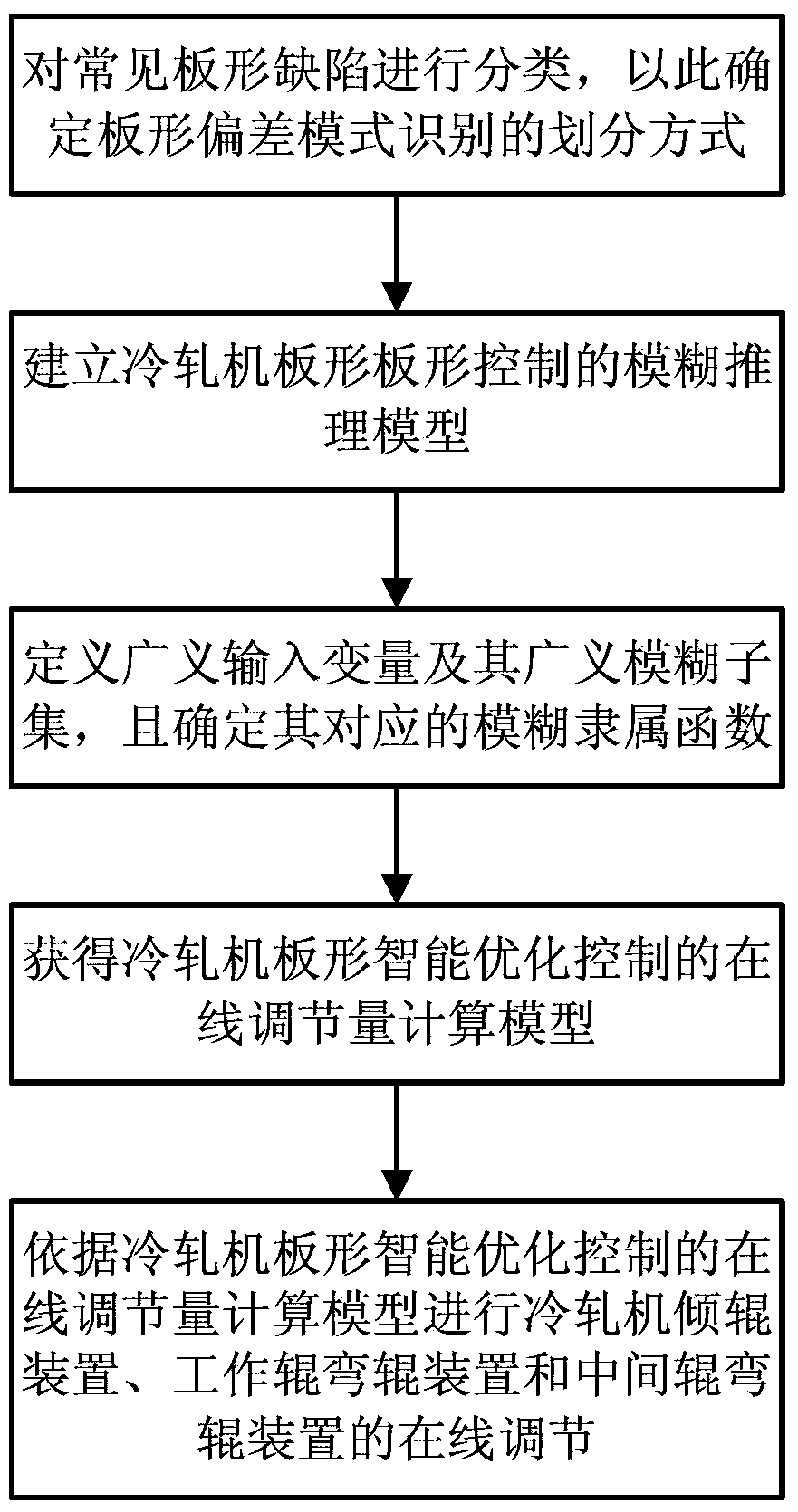

[0032] figure 1 It is a method flowchart of an embodiment of the present invention, and it comprises the following steps:

[0033] 1) Classify common plate shape defects, which are divided into: left wave, right wave, middle wave, double-sided wave, quarter wave and side middle wave; among them, left wave and right wave, middle wave and double-sided wave, and quarter wave The wave and the wave in the middle are two opposite types of plate defects, and only one of the plate defects will appear in the two at a certain moment. Based on the above principles, the shape deviation signal is divided into left wave and right wave components Δ by pattern recognition 1 , intermediate wave and bilateral wave components Δ 2 , and the quarter wave and edge-median wave components Δ 3 (unit is I);

[0034] 2) For strips of the same specification, establish the fuz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com