A cold -shaped steel plate cutting and warping method and equipment

A control method and cold forming technology, applied in metal processing equipment, manufacturing tools, metal rolling, etc., can solve the problems that residual stress cannot be released or eliminated evenly, lack of annealing process, and cannot be used normally, so as to achieve cutting warpage The effect of eliminating quality defects, eliminating or balancing internal stress, and improving the flatness of the board surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention is further described below.

[0008] A method for controlling warpage defects in cold forming steel plate cutting, including fine orthopaedic adjustment and ruler roller pressure adjustment.

[0009] 1. Adjustment of fine orthodontic machine:

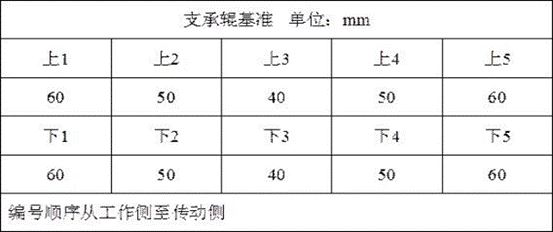

[0010] When the strip enters the cross-cutting orthodontic machine orthodontics, through the adjustment of the pressure amount, angle and support roller of the fine orthodontic machine, the upper and lower surfaces of the strip are repeatedly bent to eliminate some of the plate shape defects, improve the flatness and straightness of the plate surface, realize the elimination or equalization of the overall stress of the cold formed steel plate after shearing, and avoid the warp quality defects of the steel plate during further striping processing.

[0011] (1) Pressure reduction adjustment: When producing cold-formed steel plates with a thickness of 0.8-1.2mm, the roll seam value is set to -2.0mm~-1.5mm. When the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com