Equipment for sharpening blades

A blade and equipment technology, applied in the field of blade sharpening equipment, can solve problems such as output loss and output reduction, and achieve the effect of rapid sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

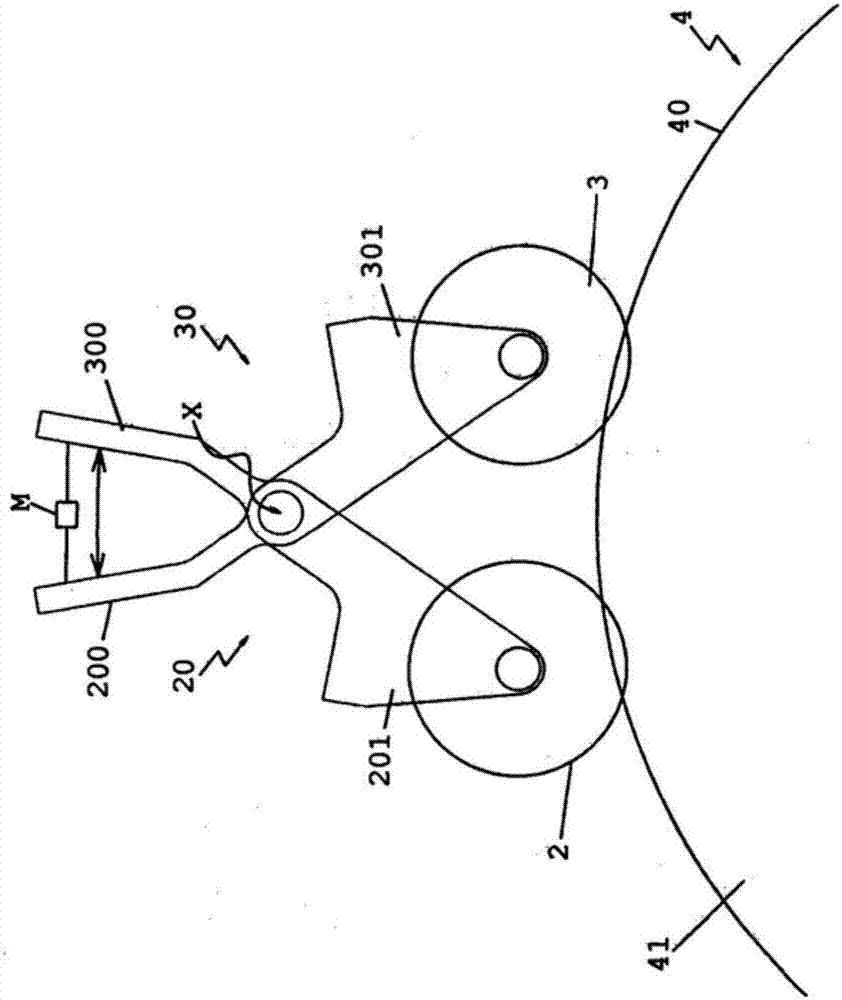

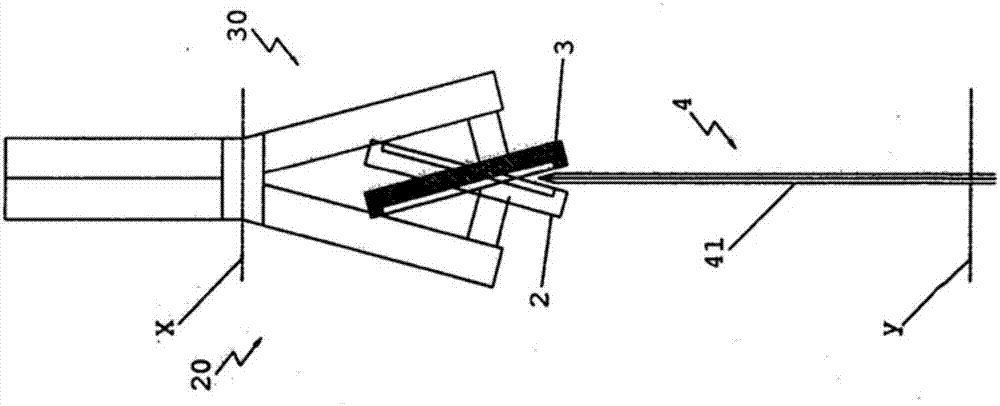

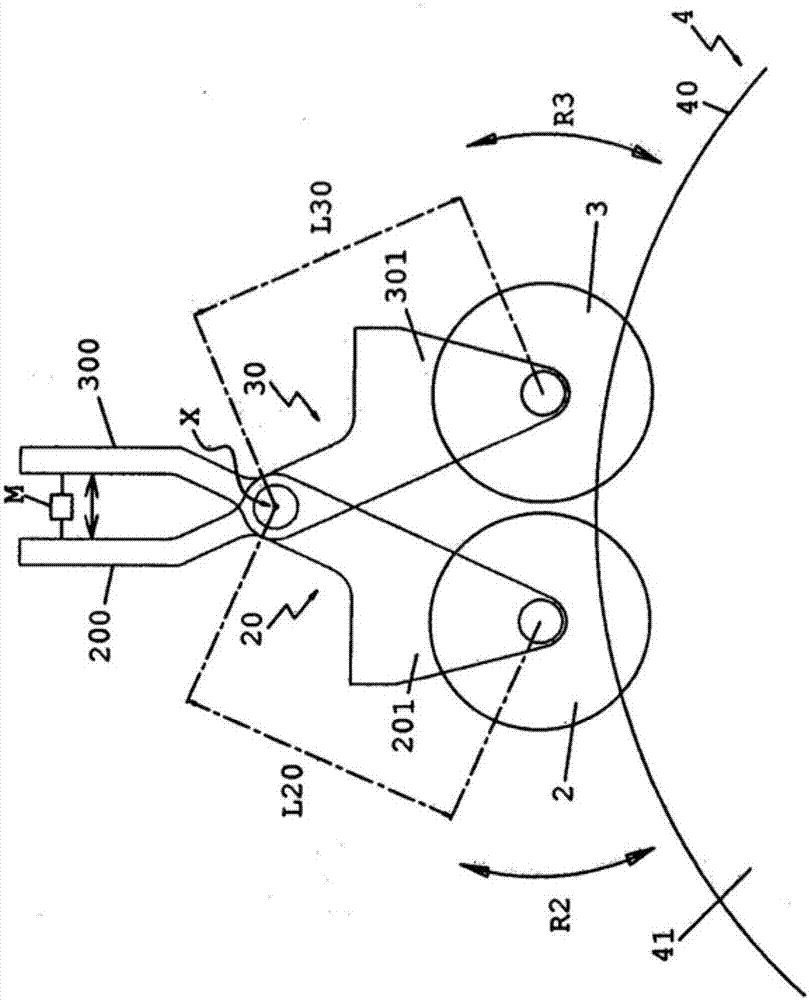

[0023] Referring to the attached drawings (especially Figure 1A to Figure 2B ), the device 1 according to the invention can be used for sharpening blades, in particular for cutting machines provided with blades 4 . The blade 4 is provided with two bevels (bevels) which are connected to each other forming a sharp or cutting edge 40 .

[0024] The device 1 comprises two grinding wheels 2, 3 supported by respective movable arms 20, 30, said arms moving said grinding wheels 2, 3 into contact with said sharpening edge 40 on command to perform a sharpening operation.

[0025] Said arms 20 , 30 form fulcrums with respect to each other so as to define a first type of double lever like scissors with the resistance constituted by the friction generated by the contact of the grinding wheels 2 , 3 with the blade 4 . The fulcrum of the double lever formed by the arms 20 , 30 has an axis x perpendicular to the cutting plane P defined by the sharp edge 40 of the blade 4 . Said axis x is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com