Vibrating assembly having rotating member

A technology of rotating parts and vibration components, applied in non-rotational vibration suppression, lateral relative movement between the chassis and the bogie, earth movers/shovels, etc. It can solve performance limitations and increase high frequency wave transmissibility. and other problems to achieve the effect of improving the vibration quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

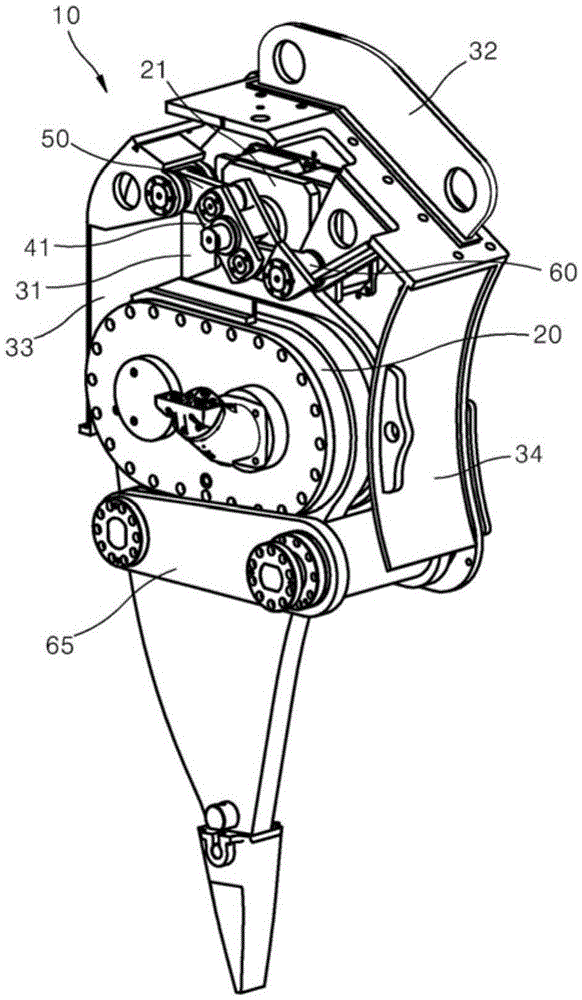

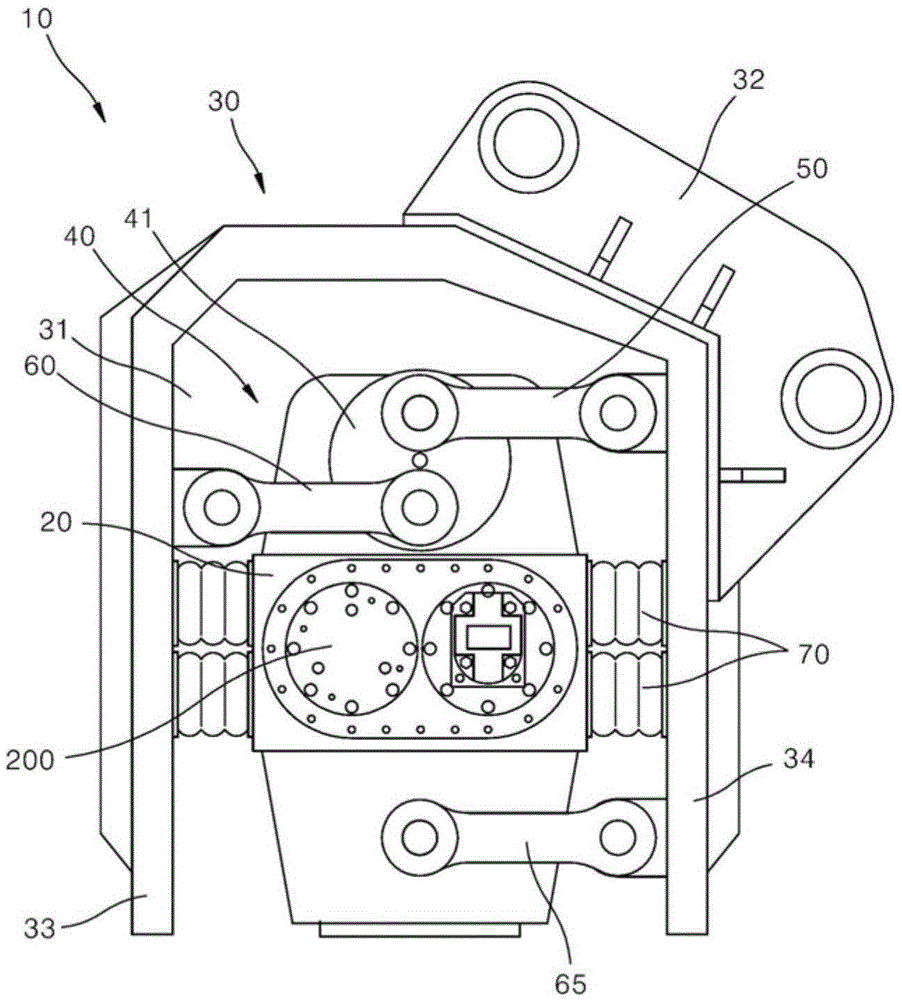

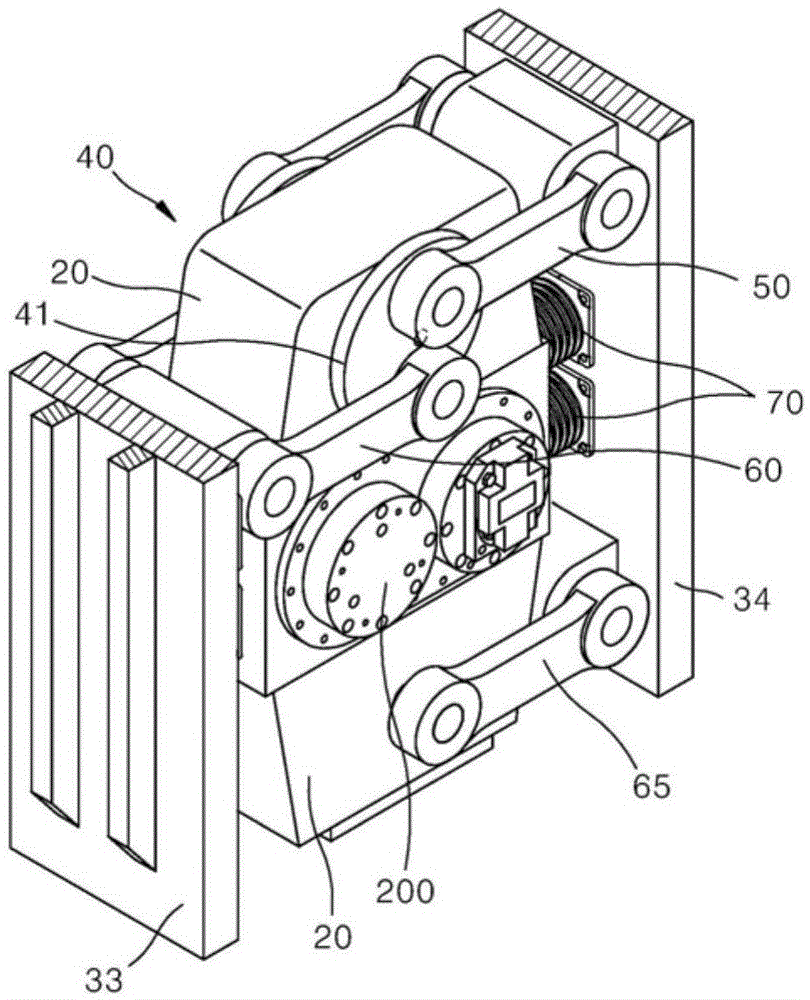

[0032] Figure 1 to Figure 5 An embodiment of a vibratory assembly with a rotating part according to the invention is shown in .

[0033] With reference to accompanying drawing, according to the vibrating assembly 10 of rotating parts of the present invention, comprise vibrating body 20, be used to support the body part 30 of described vibrating body 20 and support vibrating body 20 so that it can vibrate with respect to described body part 30 Vibrator supporting unit 40 .

[0034] The body part 30 may have a vibration space part 31 of the vibrating body 10 . Such as figure 1 As shown, the main body part 30 can be formed with a support bracket 32 on the upper side or side of the main body part 30 for combining with the operating equipment, and in order to form the vibration space part 31, a second side extending from both sides can be formed. 1. Second supporting frame parts 33, 34. The body portion 30 does not necessarily have to be additionally formed with the divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com