An automatic natural casing processing system

A processing system and casing technology, applied in the direction of cleaning the intestines, etc., can solve the problems of difficult to achieve cleanliness, low accuracy of manual measurement, bacterial contamination of casings, etc., and achieve the effects of easy promotion, simple structure, and low machine cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

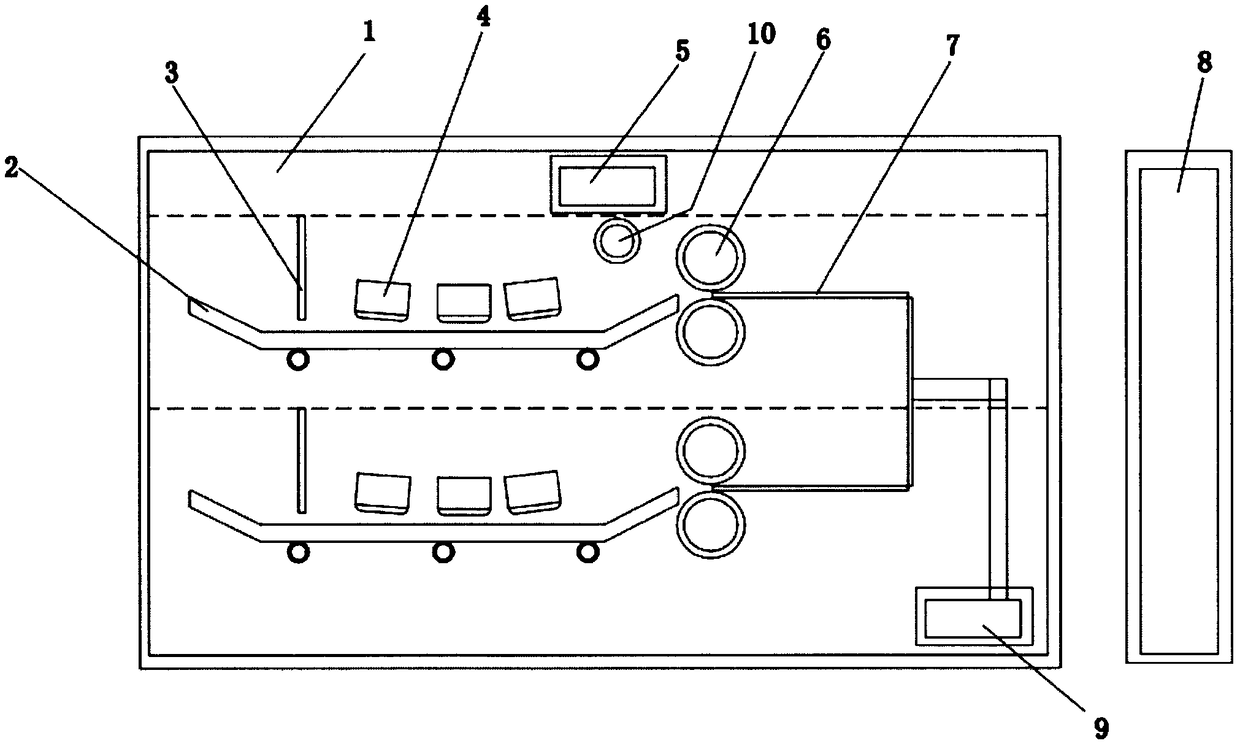

[0032] The automatic natural sausage casing processing system disclosed by the present invention will be further described below in conjunction with the accompanying drawings.

[0033] Such as figure 1 The shown automatic natural casing processing system includes a frame 1, two sets of assembly lines carried on the frame 1 and a PLC programming system for controlling the assembly line; the assembly line includes a feeding trough 2 and a distance measuring mechanism 3 , intestinal scraping mechanism 4, salt sprinkling mechanism 10, sleeve shrinkage mechanism; two groups of assembly lines share a water storage mechanism 9 or each use a water storage mechanism 9.

[0034] The distance measuring mechanism 3, the intestinal scraping mechanism 4, and the salt spreading mechanism 10 are sequentially arranged above the feeding chute 2; The groove 2 is divided into a front section, a middle section and a back section, and both the front section and the back section are inclined upward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com