Blocking prevention suction nozzle

An anti-clogging and suction nozzle technology, which is applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using gas flow, etc., can solve the problem that the suction nozzle is not easy to absorb dust from the network disk, the suction nozzle parts are stuck, and the network disk is blocked. No deadlocks and other problems, to achieve the effect of simple structure, prevent blockage, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

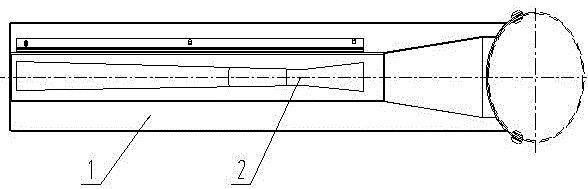

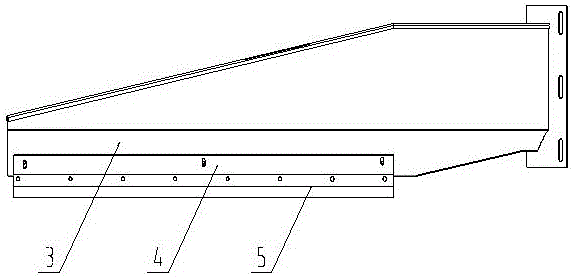

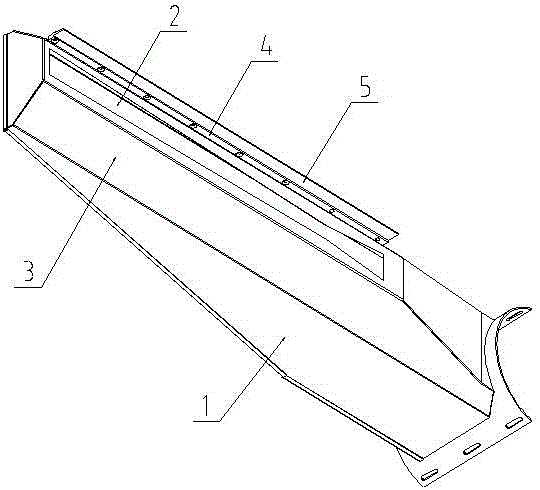

[0023] Such as Figure 1~Figure 3 As shown, an anti-clogging suction nozzle in this embodiment includes a suction nozzle body 1, a suction port 2 is provided in the middle of the bottom of the suction nozzle body 1, and bevel angles are provided on the left and right sides of the bottom of the suction nozzle body 1. 3. A fixed installation plate 4 is arranged on one side of the suction port 2, and a scraper 5 is arranged on the fixed installation plate 4, and the scraper 5 is located on the side opposite to the rotation direction of the suction nozzle body 1.

[0024] The suction port 2 adopts an hourglass shape.

[0025] The nozzle body 1 is formed by tailor welding of steel plates.

[0026] In addition to the above-mentioned embodiments, the present invention also includes other implementations, and any technical solution formed by equival...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com