Spot welder pulse output control circuit adopting transformer to output direct current pulses

A pulse output and control circuit technology, applied in welding power supply, manufacturing tools, welding equipment, etc., can solve the problems that pulse amplitude and width cannot be adjusted at will, DC pulse polarity is single, and cannot be switched at any time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

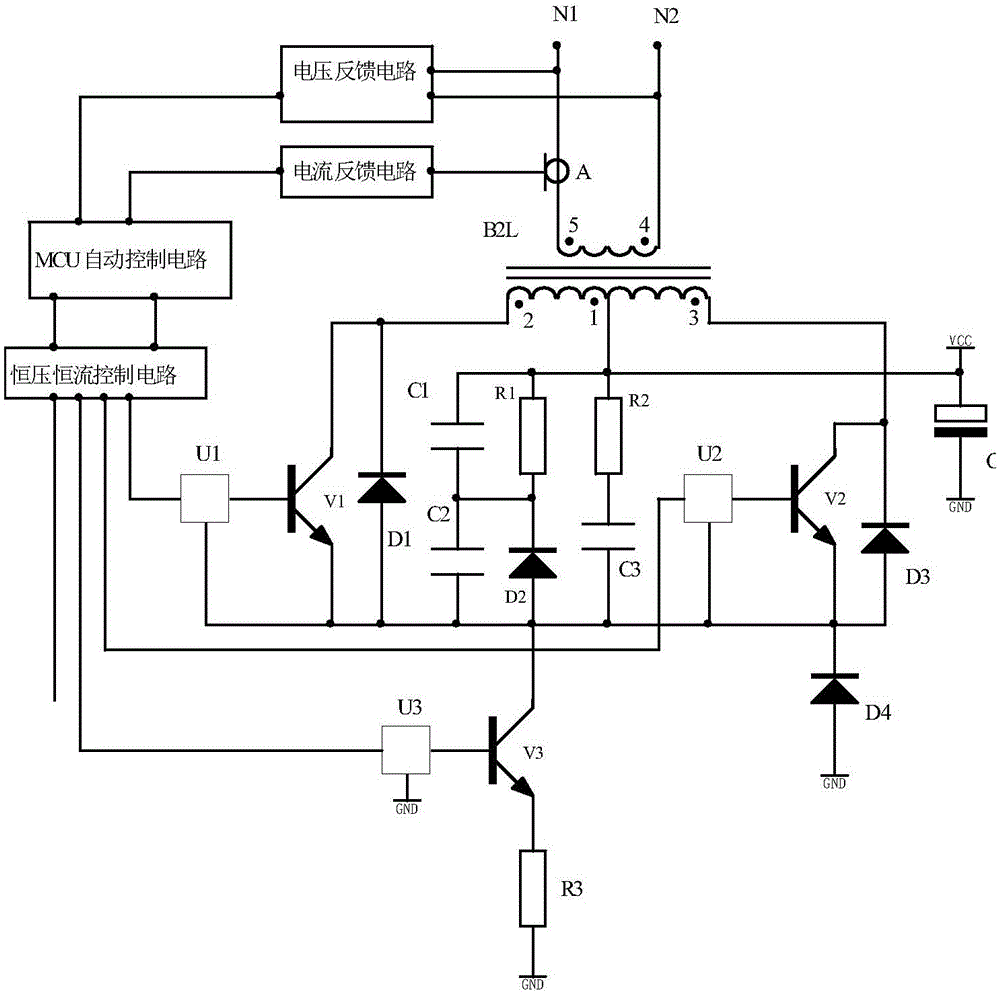

[0024] Such as figure 1 As shown, it is the spot welding machine pulse output control circuit of the first embodiment of the present invention, including MCU automatic control circuit, constant current and constant voltage control circuit, pulse transformer B2L, energy storage capacitor C, first power switch V1, second power The switch V2, the third power switch V3 and other basic components; the MCU automatic control circuit and the constant current and constant voltage control circuit belong to the conventional technology in this field, and are not the protection focus of the present invention, so the specific circuits are not disclosed here and replaced by modules. In this embodiment, the first power switch V1, the second power switch V2, and the third power switch V3 are triodes.

[0025] The connection relationship of the above components is: the output terminal of the MCU automatic control circuit is connected to the constant current and constant voltage control circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com